Operation & leakage tests, Leakage tests (figure 8), Operational tests (figure 8) – Bendix Commercial Vehicle Systems INLET REG VALVE COMP 3/04 User Manual

Page 4

4

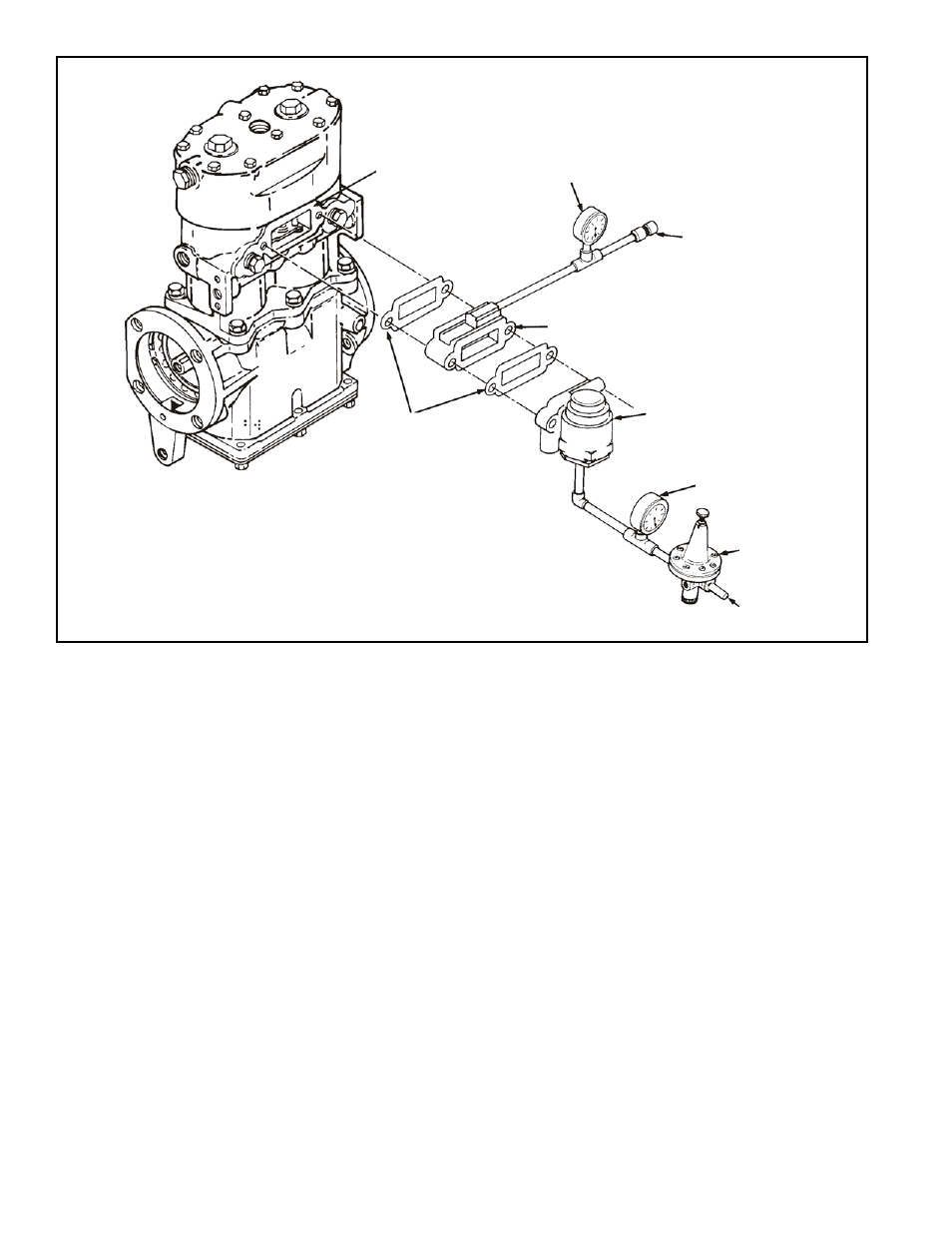

FIGURE 8 - IRV

™

VALVE TEST APPARATUS

OPERATION & LEAKAGE TESTS

(Figures 7 & 8)

GENERAL

In order to test the operation of the IRV

™

valve it will be

necessary to install the equipment and apparatus as

illustrated in Figure 8.

The Bendix compressor inlet adapter in Figures 7 and 8 can

be obtained at the nearest Bendix parts outlet. In most cases

the inlet adapter will be required, however, if the IRV

™

valve

being tested has a 1/8 inch NPT access port in the area of

its flange, the adapter is not needed.

In addition to the inlet adapter two test gauges of known

accuracy and a pressure regulating valve capable of

graduation in the 5-30 psi range will be required to complete

the tests.

LEAKAGE TESTS (FIGURE 8)

1. With the engine off and vehicle air system pressure above

15 psi, apply 15 psi shop air pressure at the turbo supply

port of the IRV

™

valve. When pressure stabilizes on test

gauge ‘A’, proceed to Step 2.

2. Using a soap solution check for leakage at the IRV

™

valve vent in the body, around the two inch cap nut and

at the exhaust plug of the safety valve. Leakage in excess

of a one inch bubble in one second is unacceptable.

OPERATIONAL TESTS (FIGURE 8)

1. Drain the air pressure from the vehicle reservoirs.

2. Apply 25 psi shop air pressure to the turbo supply port

of the IRV

™

valve, start the engine and allow it to run at

an idle (approximately 600-700 RPM). When vehicle air

system pressure rises above 25 psi, proceed to Step 3.

3. Using the pressure regulating valve and test gauge B,

adjust the shop air pressure being delivered to the IRV

™

valve in 5 psi increments between 5 and 25 psi. Pause

15-20 seconds at each pressure setting and note that

the compressor inlet pressure, as indicated by test gauge

‘A’, is 12 psi or less. If the pressure exceeds 12 psi

more than momentarily, the IRV

™

valve should be repaired

or replaced.

Note: The tests described in this step must be made

with the compressor loaded.

TYPICAL

MULTI-CYLINDER

COMPRESSOR

INLET GASKETS

(243430)

TEST

GAUGE A

ADAPTER

(236701)

COMPRESSOR

INLET CAVITY

AIR LINE

QUICK

COUPLER

TEST

GAUGE B

PRESSURE

REGULATING

VALVE

TO SHOP AIR

IRV