8 gas piping & connections – Bosch 250 SXO NG User Manual

Page 10

6 720 607 440

10

Appliance details

2.8

Gas piping & connections

Before connecting the gas supply, check the rating

plate on the right side of the heater to be sure that the

heater is rated for the same gas to which it will be

connected.

In the United States: The installation must conform with

local codes or, in the absence of local codes, the

National Fuel Gas Code ANSI Z223.1/NFPA 54.

In Canada: The Installation should conform with CGA

B149 INSTALLATION CODES and/or local installation

codes.

GAS LINE SIZING

The gas supply piping should be sized according to the

applicable plumbing code for a maximum draw of

175,000 BTUH. Measure the length of gas supply line

and use the tables in Fig. 12 or the gas line

manufactures sizing tables to determine the pipe

diameter necessary to accommodate the BTU demand

of the unit. If there are more gas drawing appliances on

the line, size the gas line according to the total maximum

amount of BTU draw for all appliances.

Note: Under sizing the gas line may result in diminished

output and improper operation. See chapter 2.9 for the

procedure to confirm gas pressure.

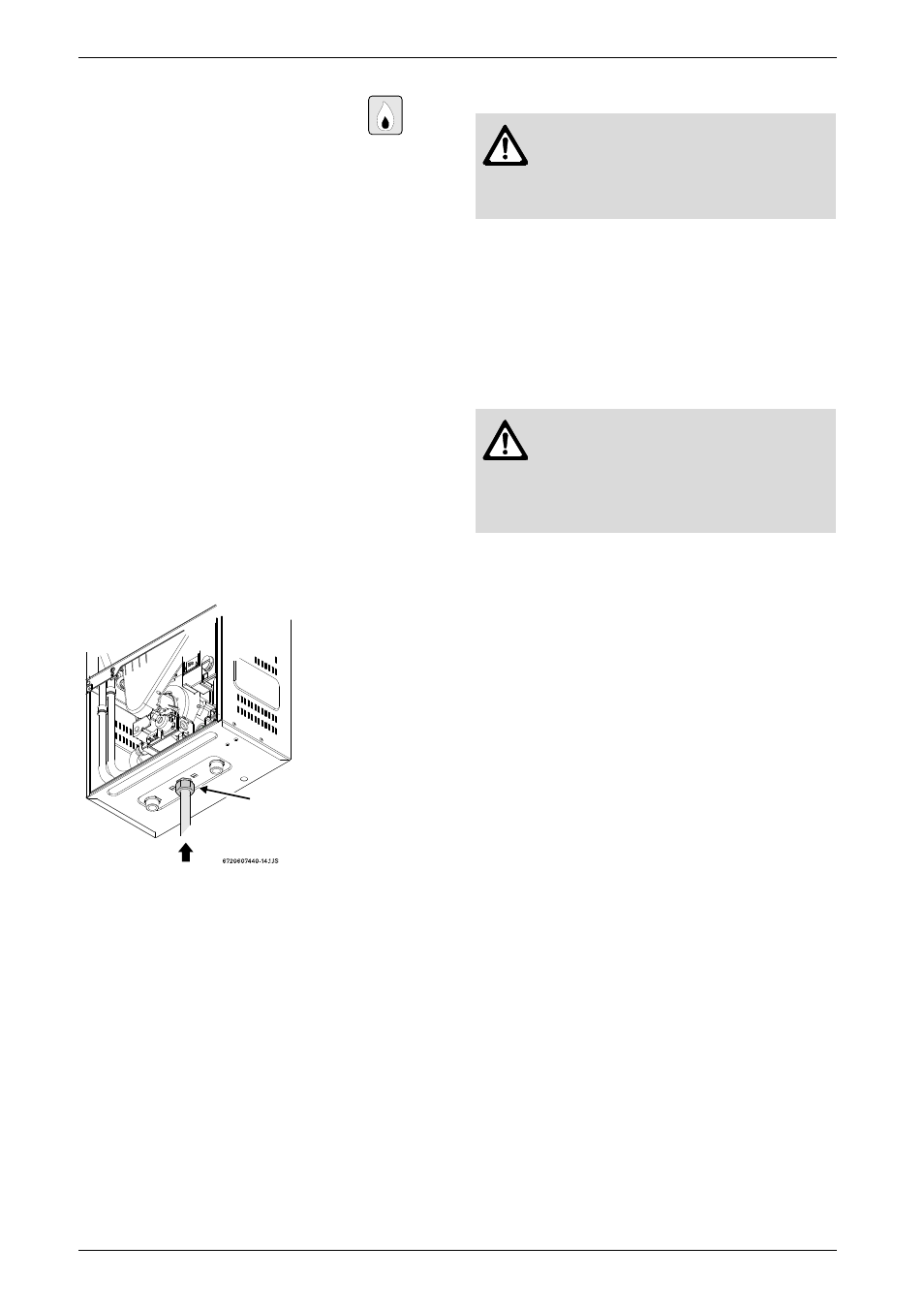

Fig. 11

B

Install a manual gas shut off valve, on the gas supply

line.

B

The use of a union when connecting gas pipe to the

gas inlet connection is important, this will facilitate

any necessary servicing and cleaning of the inlet gas

particle screen.

B

The minimum diameter required for any appliance

connector used is ¾”.

B

National Fuel Gas Code requires that a sediment

trap (drip leg) be installed on gas appliances not so

equipped. The drip leg must be accessible and not

subject to freezing conditions. Install in accordance

with the recommendations of the serving gas

supplier.

The water heater must not be piped with gas supply

pressures in excess of 0.5 psig. If overpressure has

occurred, such as through improper testing of the gas

lines or malfunction of the supply system, the gas valve

must be checked for safe operation.

When connections are made, check for gas leaks at all

joints. Apply some gas leak detection solution to all gas

fittings. Bubbles are a sign of a leak. A Combustible

Gas Detector may also be used to detect for leaks.

Gas piping

Inlet gas particle screen

Warning: The heater must be isolated

from the gas supply piping system

during any pressure testing of that

system at test pressures equal to or

more than 0.5 psig.

Danger: If you have a leak, shut off the

gas. Tighten appropriate fittings to stop

leak. Turn the gas on and check again

with a gas leak detection solution.

Never test for gas leaks using a match

or flame.