Pply the, Ad to a, Positioning the lifter on the load – Wood’s Powr-Grip FL1HV11DC User Manual

Page 12: Sealing the pad against the load

Rev 3.0/9-13

10

FL1HV11DC: #35026

CAUTION: Examine each air filter regularly, and empty when necessary.

The lifter is equipped with one or more air filters to help protect the vacuum system from

contaminants. In order for a filter to function, the operator must empty the filter bowl before

enough liquid accumulates to contact any portion of the filter element (see MAINTENANCE: A

IR

F

ILTER

M

AINTENANCE

).

T

O

A

PPLY THE

P

AD TO A

L

OAD

Positioning the Lifter on the Load

Make certain that the contact surfaces of the load and the vacuum pad are free of any

contaminates that could prevent the pad from sealing against the load (see MAINTENANCE:

V

ACUUM

P

AD

M

AINTENANCE

).

4

WARNING: To avoid accidental load release, always center lifter’s vacuum pad

on load.

Center the lifter’s vacuum pad to within 2" [5 cm] of the load center, since off-center loading

could result in a load release and possible injury to the operator, and it may also damage the

lifter.

5

Make sure that the vacuum pad will fit entirely on the load’s contact surface (see

SPECIFICATIONS: Pad Spread). Then lower the lifter onto the load until the pad is touching the

contact surface.

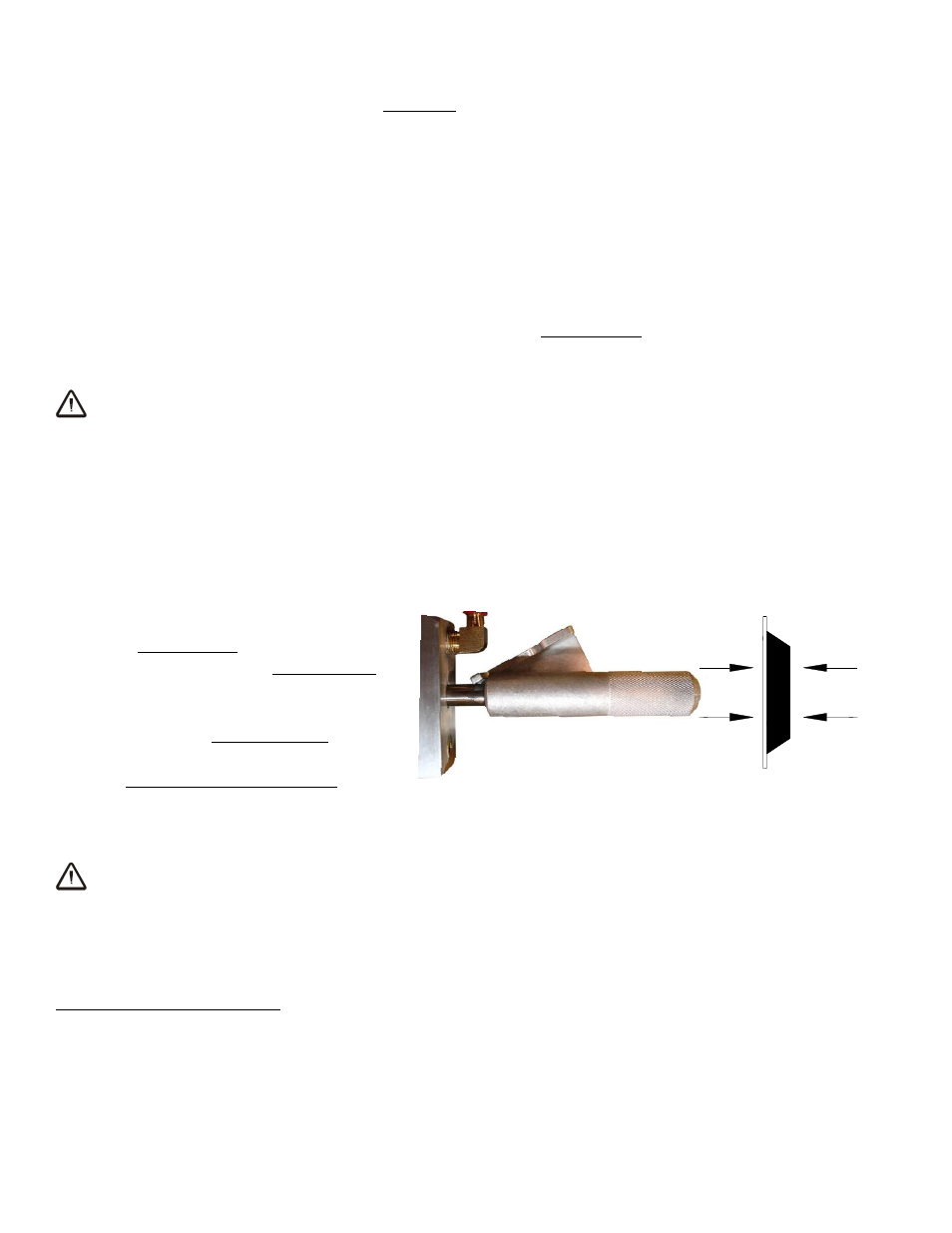

Sealing the Pad against the Load

Firm pressure at the center of the lifter

helps the vacuum pad begin to seal

against the load. Pull the valve handle

outward until it latches securely in the

“APPLY” position (power on), as shown.

This energizes the vacuum pump, causing

air to be drawn at the pad immediately.

The red low vacuum warning light also

turns on and remains illuminated until the lifter attains sufficient vacuum to lift the maximum

load weight (see T

O

L

IFT AND

M

OVE THE

L

OAD

: Load Capacity and the Warning Light to follow). The

valve handle must remain in the “APPLY” position throughout the entire lift.

WARNING: Keep valve handle latched securely in “APPLY” position throughout

lift.

Note: If a vacuum pad has been lying against a hard object (as during shipping), it may be

slightly distorted. Although initially it may be difficult to apply the pad to a load, this condition

should correct itself with continued use.

4

Since oil damages the rubber in a standard pad, the load surface must be free of oil unless the lifter is equipped with an

optional chemical-resistant pad, which may be used on oily surfaces.

5

The lifter is designed to handle the maximum load weight (see SPECIFICATIONS: Maximum Load Capacity) when the load’s

center of gravity is positioned within 2" [5 cm] of the vacuum pad’s center point. Occasional loading deviations are permissible,

provided that the operator can maintain control of the load at all times and that the load weight is low enough to avoid damaging

the lifter.

TO APPLY