Ift and, Ove the, About the tilt linkage – Wood’s Powr-Grip MRTA8HV11DC User Manual

Page 18: Using or locking out the optional tilt lock

Rev 10.0/9-13

16

MRTA8-DC: #35076

T

O

L

IFT AND

M

OVE THE

L

OAD

About the Tilt Linkage

WARNING: Make sure load is positioned correctly on lifter; unbalanced loads

may tilt unexpectedly.

The lifter’s tilt linkage is designed to automatically hold a balanced load in either the upright or

the flat position. However, an unbalanced load may tilt unexpectedly from the flat position to the

upright position or vice versa, when lifted. This could result in load damage or injury to anyone

positioned in the tilt path of the load. To minimize the potential for these problems, make certain

prior to lifting any load

that it has allowable characteristics (see INTENDED USE: L

OAD

C

HARACTERISTICS

) and is attached correctly to the lifter (see T

O

A

PPLY THE

P

ADS TO A

L

OAD

preceding).

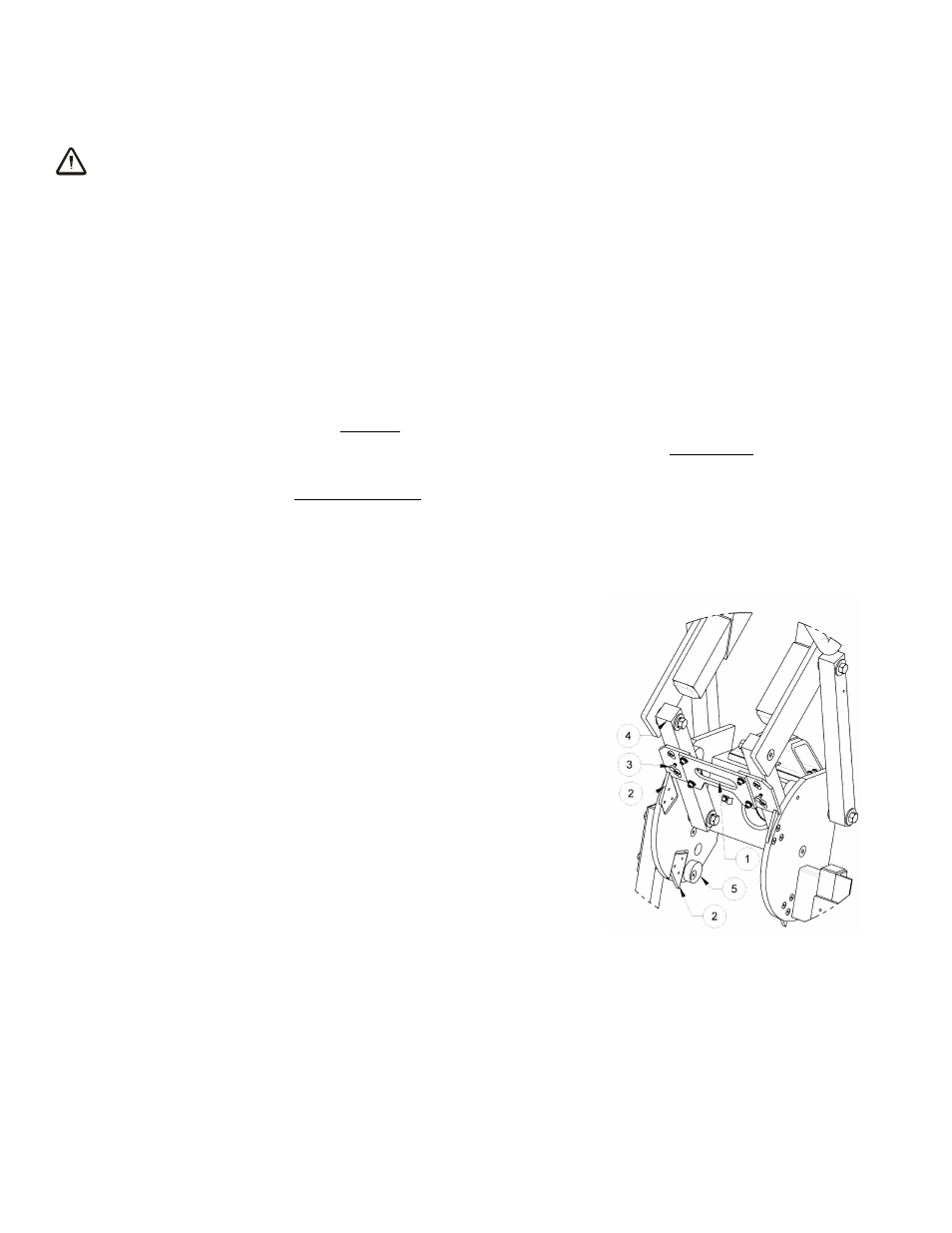

Using or Locking out the Optional Tilt Lock

When a lifter is equipped with the tilt lock, it can be used to prevent unexpected tilting motion.

Since the lifter is designed to maintain either the vertical or the horizontal pad frame orientation

when correctly loaded, the tilt lock should only be needed if the operator is not able to maintain

control of the load using the control handles or other appropriate means. For example, if the

lifter is being used to install glass in a multi-story building, engaging the tilt lock would prevent

the load from accidentally tilting due to wind loads or other causes of incidental loading. The tilt

lock is intended as a secondary safety device and does not eliminate the need to center the load

correctly on the pad frame (see T

O

A

PPLY THE

P

ADS TO A

L

OAD

: Positioning the Lifter on the Load

preceding). Failure to center the load may damage the lifter and would

make it difficult to operate the lock.

The tilt lock can be set to engage automatically when the pad frame

reaches the vertical or horizontal position, or it can be locked out,

depending on the application. To allow automatic locking, make

sure the lock plate/handle (1) is set to engage the lock catches

(2). If not, pull outward on the round knobs of the spring

plungers (3) and turn them 90° to release the lock plate/handle.

Make sure that the lock plate/handle slides freely along the tilt

linkage (4) before you attempt to tilt the pad frame. If the lock

plate/handle does not engage the catches or if the pad frame

exhibits excessive play in either the vertical or the horizontal

orientation, the stop cams (5) for the tilt linkage may require

adjustment. Once the tilt lock is set to the automatic mode, simply

pull on the lock plate/handle to disengage the lock.

To lock out the tilt lock, make sure the lock plate/handle is secured so

that it

cannot

engage the catches. If otherwise, turn the round knobs of

the spring plungers 90° and then slide the lock plate/handle upward until

the spring plungers engage. Make sure that the lock plate/handle does

not slide along the tilt linkage.

1 LOCK PLATE/HANDLE

2 LOCK CATCHES

3 SPRING PLUNGER

4 TILT LINKAGE

5 STOP CAM