Thrush TV2g In-Line Centrifugal Pumps User Manual

Page 3

OPERATION

CAUTION: Centrifugal pumps should never be started or run dry. Operating a pump dry

will cause scoring of the mechanical seals, resulting in premature seal failure. To prevent

the pump from being run dry, it should be primed before starting. Failure to do so will

void any warranties.

PRIMING THE PUMP

The pump will not operate satisfactorily until it is primed. All air must be expelled from the suction

piping and pump casing and replaced by the liquid to be pumped. There are several methods of

priming pumps. The one selected will depend on the specific requirements.

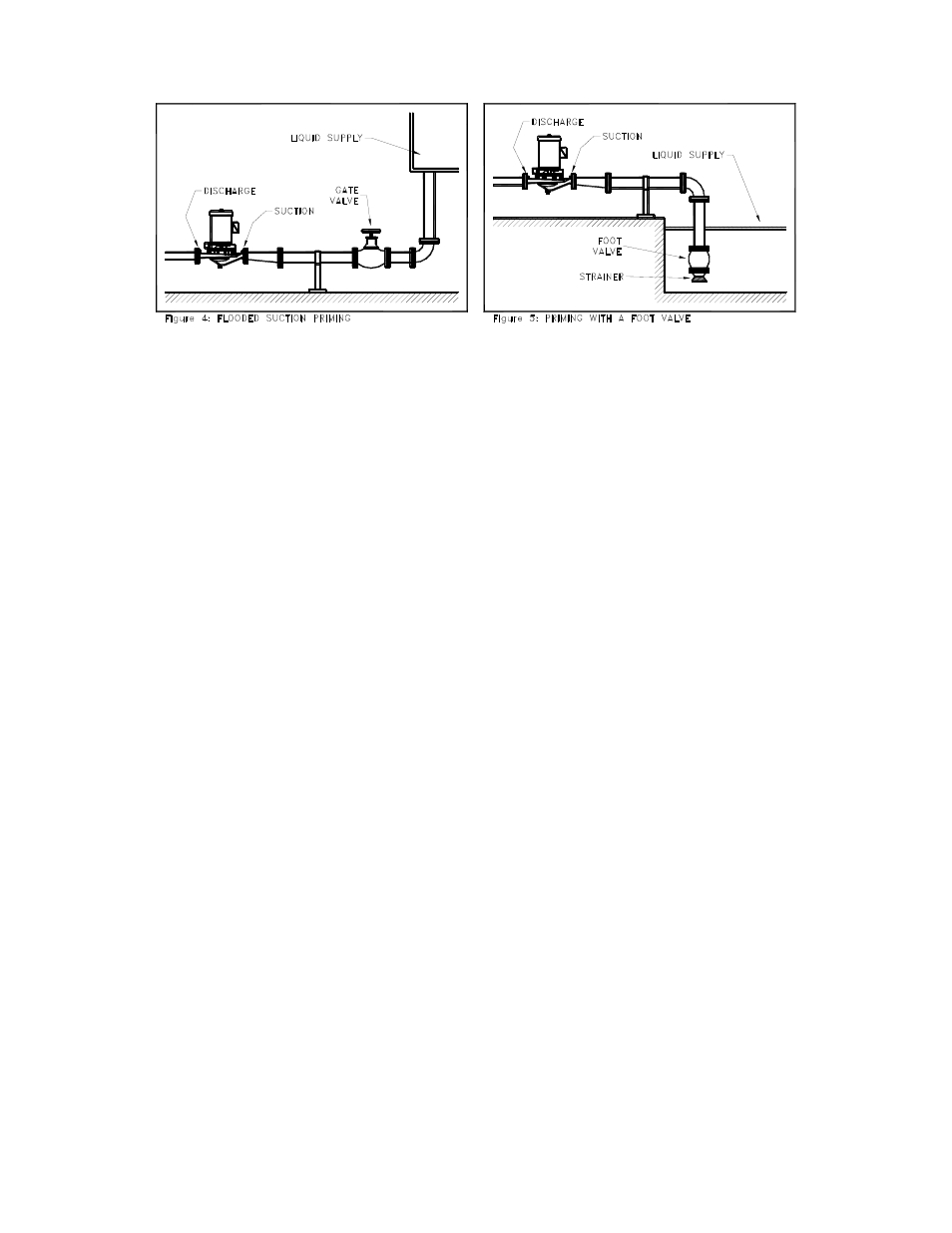

FLOODED SUCTION PRIMING

This method of priming a pump is relatively simple (See Figure 4). The liquid source is located

above the pump and all that is necessary to prime the pump is to open the air vent valve or plug

in the pump casing and to crack the isolating valve in the suction line. The suction line and pump

should be filled slowly until a steady stream of liquid is observed flowing from the air vent. After

the pump is operating, it is recommended that the air vent valve or plug be opened again to

insure that all air has been expelled form the pump casing.

SUCTION LIFT

A foot valve should be used for priming on suction lift applications (See Figure 5). The foot valve

located at the bottom end or foot of the suction piping functions as a check valve, which allows

flow in one direction only, toward the pump. Otherwise, all the liquid may drain from the pump

and suction piping back into the sump after shutdown.

Initial priming is accomplished by completely filling the suction piping and pump casing with the

liquid to be pumped. This can be done by removing the air vent valve or plug at the top of the

pump casing and inserting a pipe nipple in the orifice with an appropriate increaser to

accommodate a hose connection. A priming line can also be inserted in the discharge piping

between the check valve and the pump, or the priming can be done with a bucket and funnel.

The important thing is to completely fill the suction pipe and pump casing with liquid.

When the pump is started, the vacuum created by pumping the priming fluid, combined with

atmospheric pressure in the liquid well forces liquid into the suction piping, thus opening the valve

and keeping it open until the pump is shut down. When the pump is shut down, the liquid being

pumped reverses its flow causing the valve to close. The liquid is now trapped in the suction

piping and pump casing, thus maintaining a prime on the pump.