Thrush OLD User Manual

Thrush Pumps

9636-0160

8/08

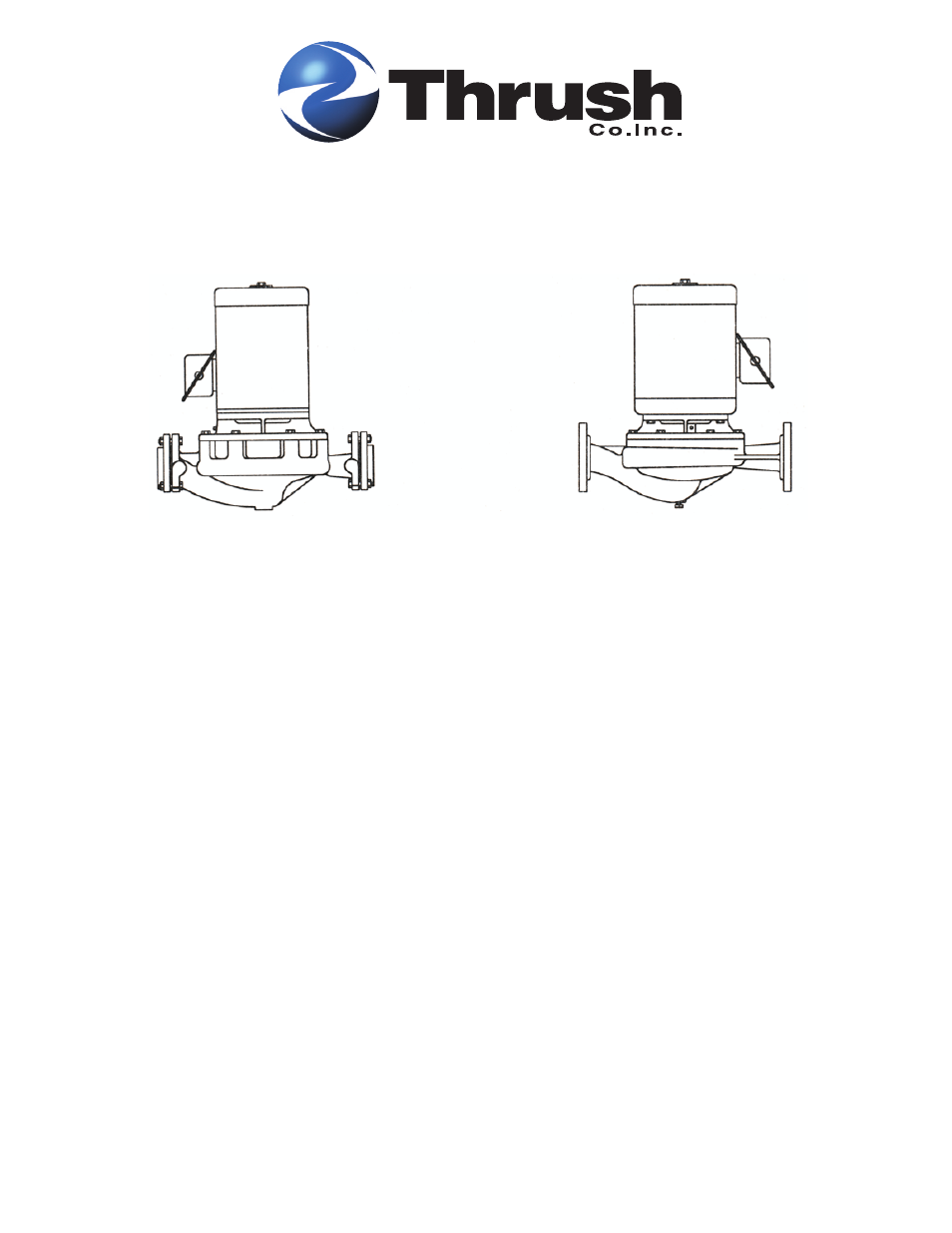

MODEL GTV, TVB & OLD STYLE TV IN-LINE CENTRIFUGAL PUMPS

FOR

OPERATING & MAINTENANCE INFORMATION

GTV

TVB & OLD STYLE TV

LOCATION

The pumps should be located as close to the liquid source as possible so that the suction line can be short and direct.

It should be located in a clean, open area, where it is easily accessible for inspection, lubrication and repair. Pumps

installed in dark, dirty areas or in cramped locations are often neglected which can result in premature failure of both the

pump and the driver.

Adequate provisions should be made for electrical wiring to the pump motor. A switch and overload protection should be

installed near the pump. The flexible electrical conduit should be used in connecting motor wiring.

MOUNTING

THRUSH In-line pumps conserve floor space, simplifies piping and can be serviced without disconnecting piping.

They are designed to be installed in either the vertical or horizontal position. The proper installation of these pumps is to

install them as part of the piping. The pumps must be free to travel with the expansion and contraction of the piping.

In-line installation eliminates the problems normally encountered in aligning piping to a bas mounted unit. SUPPORT

OF THE GTV, TVB, AND OLD STYLE TV SERIES PUMPS SHOULD ALWAYS BE CONNECTED TO THE PIPING

RATHER THAN TO THE PUMP CASING. The line-mounted feature eliminates the need for installing flexible pipe con-

nectors at either the pump suction or discharge. Isolating valves should be installed at both the pump suction and dis-

charge to permit servicing of the pump without draining the entire system. Make certain the space above the pump is

sufficient to give clearance for lifting the pump assembly from the casing. Also the space around the pump should be

large enough for general accessibility and ventilation. The same criteria and formula for selecting piping supports are

used with the additional consideration that the weight of the pump is concentrated at one point in the piping.

PIPING

The piping practices followed will directly affect the efficiency and power consumption of the pump. Pay particular

attention to the seemingly insignificant details involved in piping for they make the difference between a good and bad

installation. BOTH THE SUCTION AND THE DISCHARGE PIPING SHOULD BE INDEPENDENTLY SUPPORTED

NEAR THE PUMP. LIBERAL USE OF THE PIPE HANGERS AND SUPPORT BLOCKS WILL PREVENT EXCESSIVE

STRAIN ON THE PUMP CASING AND ON THE PIPE JOINTS. The suction diameter should be at least the same

diameter as the suction nozzle on the pump, preferably larger. Use of a smaller diameter pipe will result in loss of head

due to friction. All joints must be tight to maintain prime on the pump.