Thrush co – Thrush DSHE Series User Manual

Page 25

Thrush Co.

Manual #9636-0555

5.2 Maintenance (Continued)

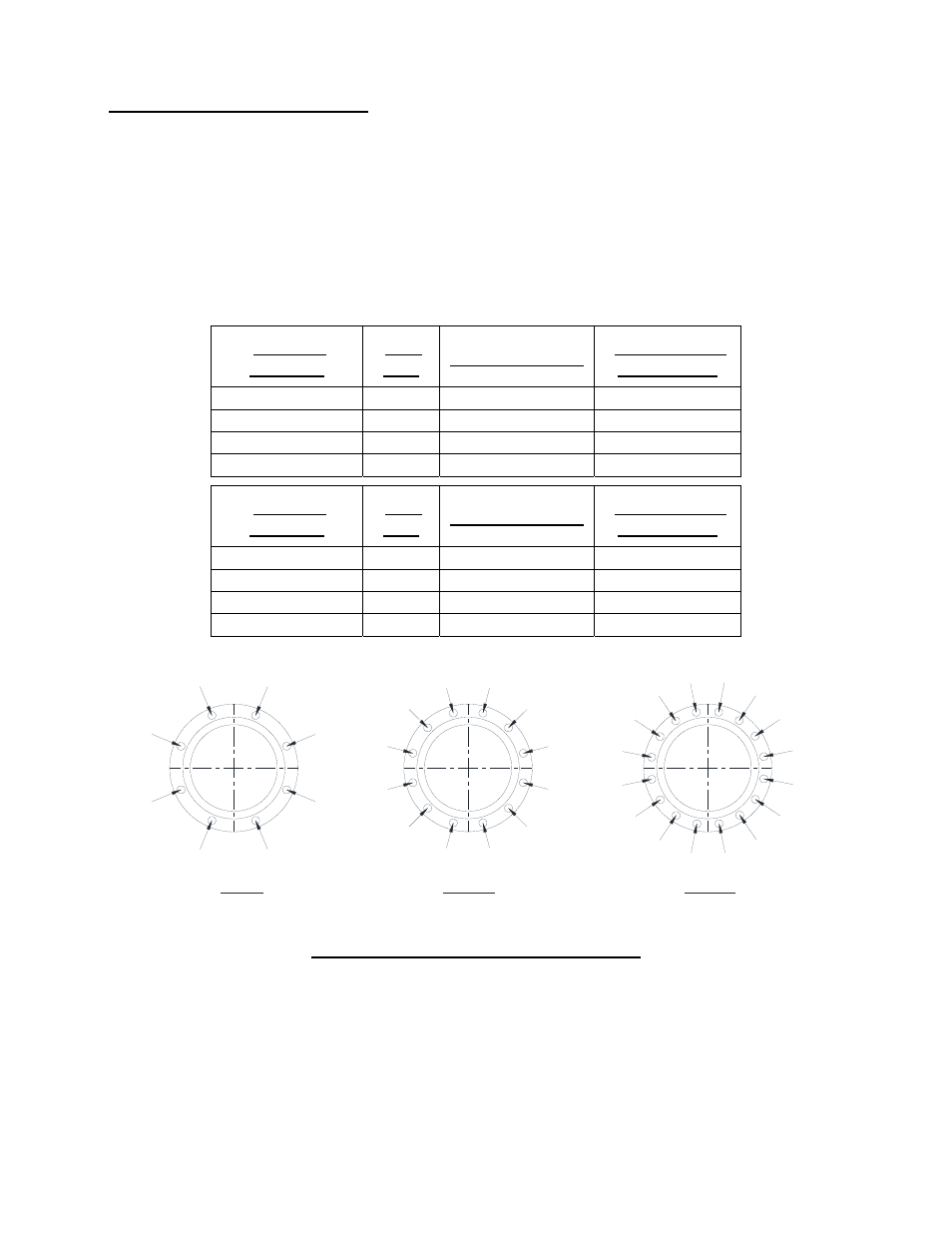

Gasket Creep is inherent to most gasket joints, and retorquing is required. The greater

the operating temperature, and pressure, the greater the problem can become. It is

imperative that the head bolts be torqued after installation, after initial startup, and

inspected seasonally to be sure the bolts are torqued correctly. The bolts should be

torqued incrementally to 30%, 60% and then to 100% of the appropriate value shown in

Figure 5-2. They should be torqued in the sequential order of the appropriate pattern

shown. Bolt holes in the tubesheet are threaded; therefore, the nuts on both the top and

bottom of the flange must be torqued.

1

12

8

4

10

6

2

11

7

3

9

5

1

8

4

6

2

7

3

5

12 Bolt

8 Bolt

16 Bolt

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Figure 5-2 Bolt Torque Requirements

Hot-Pak

Diameter

Bolt

Size

Number of Bolts

Torque Ft/Lb

(150# Flgs.)

6” .75 8

50

8” .75 8

50

10” .87 12

80

12” .87 12

80

Hot-Pak

Diameter

Bolt

Size

Number of Bolts

Torque Ft/Lb

(300# Flgs.)

6” .75 12

100

8” .87 12

160

10” 1.00 16

245

12” 1.12 16

390