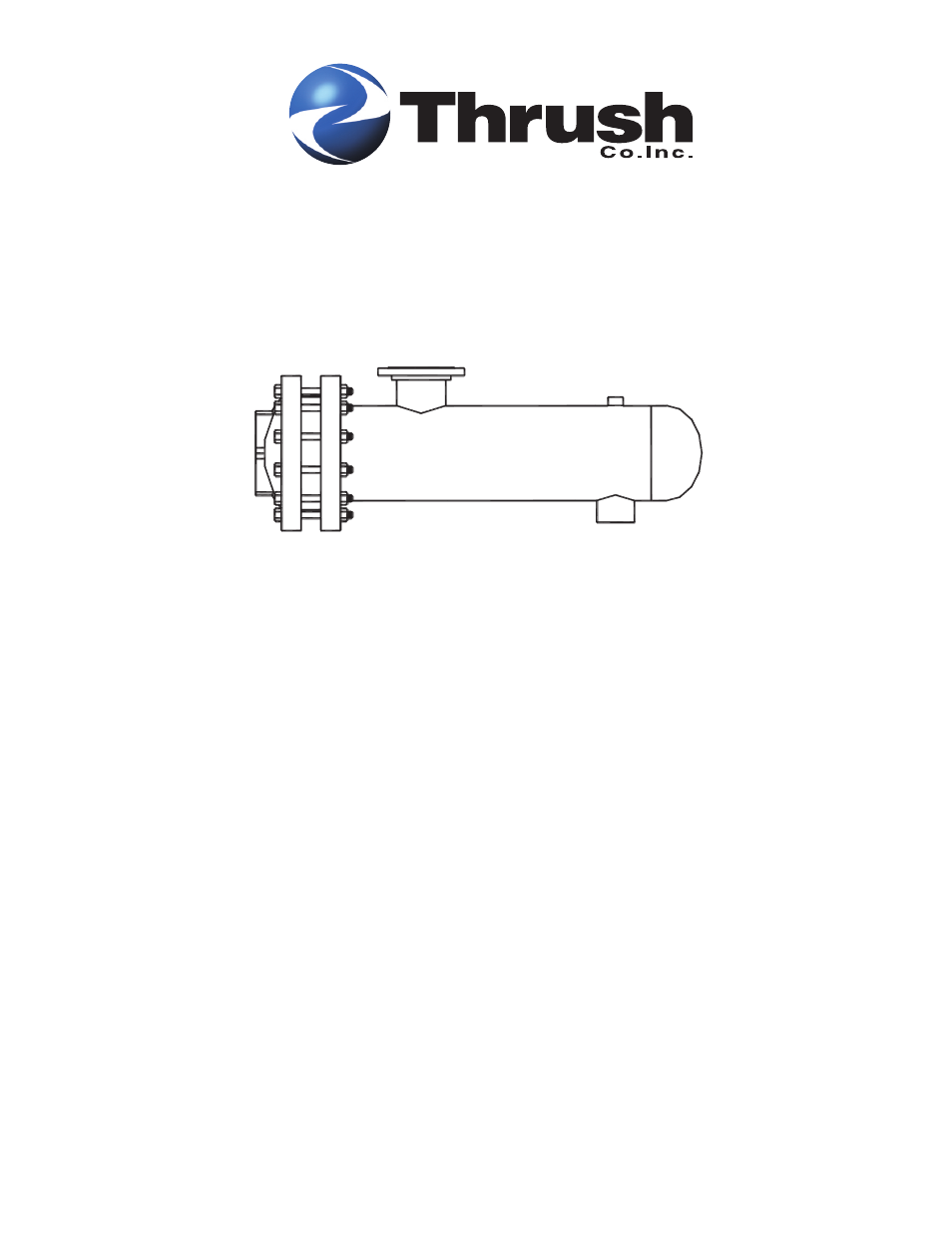

Thrush Double Wall Steam to Water U-Tube Heat Exchanger User Manual

Thrush Equipment

9636-0760

8/08

Shell and Tube Heat Exchanger - U-tube style

The THRUSH Heat Exchanger has been carefully assembled and factory tested to provide years of

trouble-free service. In order to assure the service intended, the following information is provided to

enable proper installation, operation and maintenance of the Thrush Heat Exchanger.

LOCATION

The heat exchanger should be located in a clean, open area, where it is easily accessible for

inspection, service and repair. Allowance should be made for the clearance required to remove the

tube bundle.

PIPING

Long radius elbows should be used in place of standard elbows wherever possible, because of their

superior flow characteristics. Liberal use of shut off valves is recommended to enable inspection

and service.

INSTALLATION

1.

To move or lift the heat exchanger, place a sling around the unit's inlet and outlet

connections. Verify that all equipment, including the sling, is certified to handle the total

weight of the heat exchanger. Carefully lift to piping site. Avoid slinging at the bolted gasket

head joint area.

2.

Install unit level and square so pipe connections can be made without force. During

installation and operation, unit should be adequately supported to prevent settling that could

cause piping strains.

3.

Provide sufficient clearance at channel end for removal and replacement of tube bundle.

(Minimum clearance = one length of the shell)

4.

Provide positive shutoff valves and by-pass to permit both shell and tubeside to be shut off for

inspection and service.

5.

After installation and prior to startup all head flange bolts should be re-tightened.

OPERATING & MAINTENANCE INFORMATION

FOR

HEAT EXCHANGERS