Thrush Pressurizer-VS PB-VSI Series User Manual

Page 8

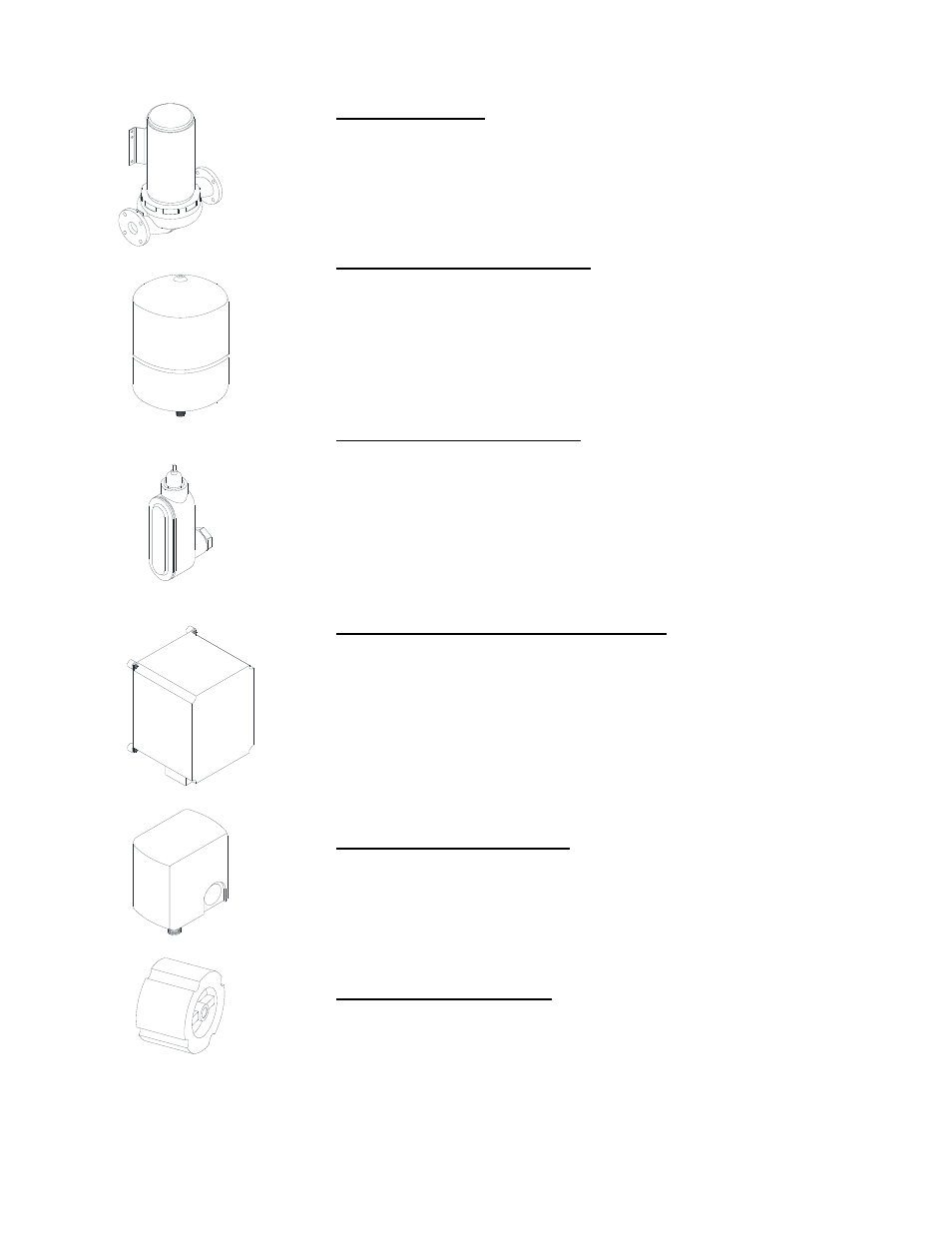

3.1.1 TV2g Pump

The TV2g series pump utilized on the Pressurizer-VS is

designed to mount in-line to reduce the overall footprint of the

system. The top pull out feature allows maintenance of the

pump mechanical seal without disturbing the piping.

3.1.2 Hydro-Pneumatic Tank

The hydro-pneumatic tank is a pre-pressurized tank that

enables the system to react instantaneously upon demand. It

also prevents the pump from short cycling from small

infrequent demands, this feature is called “Sleep Boost”. An

optional ASME Code tank is also available.

3.1.3 Pressure Transmitter

The pressure transmitter measures pressure at the discharge

side of the system. When pressure on the discharge side of

the system reaches the set-point, the pressure transmitter

sends a signal to shut the pump off. The pump will not turn

back on until the discharge pressure of the system drops

below the set-point.

3.1.4 VFD (Variable Frequency Drive)

The VFD regulates the motor and provides a constant output

pressure, regardless of fluctuating supply pressure or

changing flow demand. The VFD allows for a narrower

pressure deadband

(the amount of pressure that must be

removed before the pressure switch contacts reset after

actuation level has been reached) which insures a constant

pressure supply at fixtures.

3.1.5 Low Suction Switch

The low suction switch acts as a safeguard for the pump. If

suction pressure is below the factory set-point, the low suction

switch will prevent the pump from turning on and potentially

causing damage.

3.1.6 Inline Check Valve

The inline check valve is located at the pump discharge to

prevent possible damage to the pump from water backflow

and back pressure. This compact design reduces the overall

footprint of the Pressurizer-VS.

Thrush Co.

Manual #9636-1400

4