TCI V1k User Manual

Page 2

V1k KLC-Series Motor Protection Filter Installation

Instructions

Installation Checklist

•

Make sure that the installation location will not be

exposed to direct sunlight, rain or dripping liquids,

corrosive liquids or gases, explosive or combustible

gases or dust, excessive airbourne dirt and dust, or

excessive vibration.

•

Select a mounting area that will allow adequate

cooling air and maintenance access.

•

Make sure that all wiring conforms to the

requirements of the National Electric Code (NEC)

and\or other applicable electrical codes.

•

Ground the V1k Ouptut Filter to a dedicated system

ground to ensure safety and filter performance. Use a

properly sized grounding conductor.

•

Wire the output power terminals of the VFD, T1(U),

T2(V), & T3(W) to the input terminals of the V1k,

A1, B1 & C1.

•

Wire the output power terminals, of the V1k, A2, B2

& C2 to the motor power connections.

•

Make sure the VFD is set for operating modes and

ranges that are compatible with the V1k Output Filter.

•

Check the entire system throughly before energizing

and operating any equipment.

• Current Rating: 2 - 750 Amps, 240 V - 600 V,

7.5 - 600 HP

• cUL

• Open, UL Type 1 and 3R Enclosures

• Efficiency > 98%

• Insulation Rating: 600V Class

• Insulation Class: Class H (180°C or better)

• Maximum Altitude: 2000 m (6,000 ft) Derating

necessary above 2000 m

• Lead Length: Specific applications can reach

3,000 feet (consult factory for applications above

1,500 feet)

• Ambient Temp: Max 40°C

Product Specifications

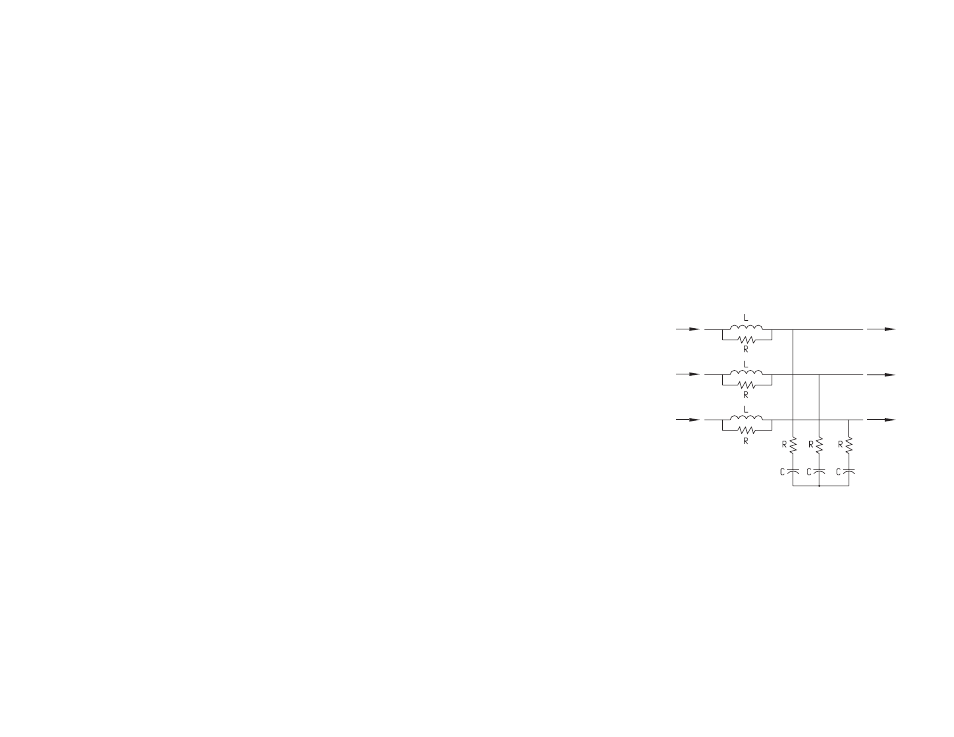

Wiring Diagram

When you receive the unit, you should immediately inspect

the shipping container and report any damage to the

shipping carrier who delivered the unit.

Verify the Application

Make sure the V1k drive output filter is correct for the

application. The current rating of the V1k should be sized

to handle the FLA rating of the motor but not to exceed

110% of the drive output current rating. This output filter

is best applied matched closely to the load. The V1k drive

output filter is not selected by the drive input current rating.

Properly sized and applied, TCI guarantees that the V1k

will limit motor terminal peak input votage to 150% of the

bus voltage with a wire lead length of 1000 feet and a carrier

frequency of 4kHz. Maximum lead length and carrier

frequency can vary depending on wire lead type. For best

performance, the V1k should be installed within 10 feet of

the drive.

Variable Frequency Drive Settings

Make sure that the variable frequency drive will be set for

operation modes and ranges that are compatible with the

V1k output filter:

•

Maximum output frequency: 60 Hz

•

PWM switching frequency best between 2kHz and

4kHz

•

Mode of operation: Do not use with DC braking unless

the drive application has been confirmed by TCI

Technical Support

•

Do not use on overhauling loads without bus voltage

control.

Mounting and open panel unit

If you are mounting an open panel unit in your own

enclosure, you must provide an enclosure that is adequately

sized and ventilated sufficiently to prevent overheating. The

filter is designed with a maximum ambient temperature of

40° C (104°F). If the ambient temperature exceeds this value

it is the responsibility of the customer to provide auxiliary

cooling to reduce the ambient operating temperature

around the V1k filter. TCI strongly recommends using

auxiliary cooling devices such as cooling fans, heat

exchangers, or possibley air conditioning units when

required to maintain the proper operating temperature.

The V1k must be mounted vertically on a smooth, solid

surface, free from heat, dampness, and condensation.

Mounting it verticallly is important for natural convection

cooling. A metal plate is provided to mount the V1k on a

composite surface.

Power Wiring

The conduit and wiring from the output of the variable

frequency drive to the motor must be routed to the V1k

and then to the motor. TCI recommends a separate

dedicated conduit run for each drive/filter/ motor run

unless properly shielded and segregated wiring procedures

are practiced. Parasitic and induced capacitance can

greatly reduce the effectiveness of the filter performance.

Under no circumstances should you wire both control

and power wire in the same conduit unless the wire way

is specifically designed for this practice. The line reactor

temperature is sensitive to lead wire oversizing. Avoid lead

wires more than five times oversized by copper cross

sectional area regarldess of the material used. Use 75°C

copper conductors only or the equivalent, unlesss the wire

connector is marked for AI/Cu, then the use of aluminum

wire is permitted. Use only copper conductor on units

rated above 80 amps.

Wiring Cable Entry Locations

TCI has provided enclosure knock-outs on the two smaller

enclosures for incoming and outgoing power cables.

These are located in a typical wiring location for customer

convenience. On the two larger size enclosures, TCI has not

provided knock-outs due to the wide variety of application

requirements. TCI allows installing electricians the option

of locating the cable openings at a point of their choosing.

Grounding

The V1k filter must be connected to the ground of

the premises wiring system. This can be conducted by

identifying a known premises ground near by the filter or

running a special ground dedicated for the application. The

ground connection must be made using a wire conductor.

Metallic conduit is not a suitable grounding conductor. The

integrity of all ground connections should be periodically

checked.

A1

B1

C1

B2

A2

C2