Warning – Schwank premierSchwank IQ User Manual

Page 42

42

STS-JZ-F / IQ-F I&O Manual

IM101220

RD: AUGUST 2014

RL: 18A

Flame Fault

If at any time the main valve fails to close completely and maintains a flame, the full time flame

sense circuit will detect it and energize the combustion blower. Should the main valve later

close completely removing the flame signal, the combustion blower will power off following the

optional post purge period.

Fault Conditions

The LED will flash on for 1/4 sec-

ond, then off for 1/4 second during

a fault condition. The pause be-

tween fault codes is 3 seconds.

MOUNTING AND WIRING

The Series 35-61 is not position sensitive and can be mounted vertically or horizontally. The

case may be mounted on any surface with #6 sheet metal screws. All wiring must be done in

accordance with local and national electrical code. Refer to wire diagram page 35 when con-

necting the Series 35-61 to other components in the burner.

The Series 35-61 DSI Control uses voltages

of shock hazard potential. Wiring and initial

operation must be done by a qualified service

technician. The control must be secured in an

area that will experience a minimum of vibra-

tion and remain below the operating tempera-

ture of 160ºF. All connections should be

made with UL approved 105ºC rated 18

gauge, stranded, .054 thick insulated wire.

Refer to wire diagram page 35 when con-

necting the Series 35-61 to other compo-

nents in the burner.

CAUTION:

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation. A functional checkout of a replacement control is recommended.

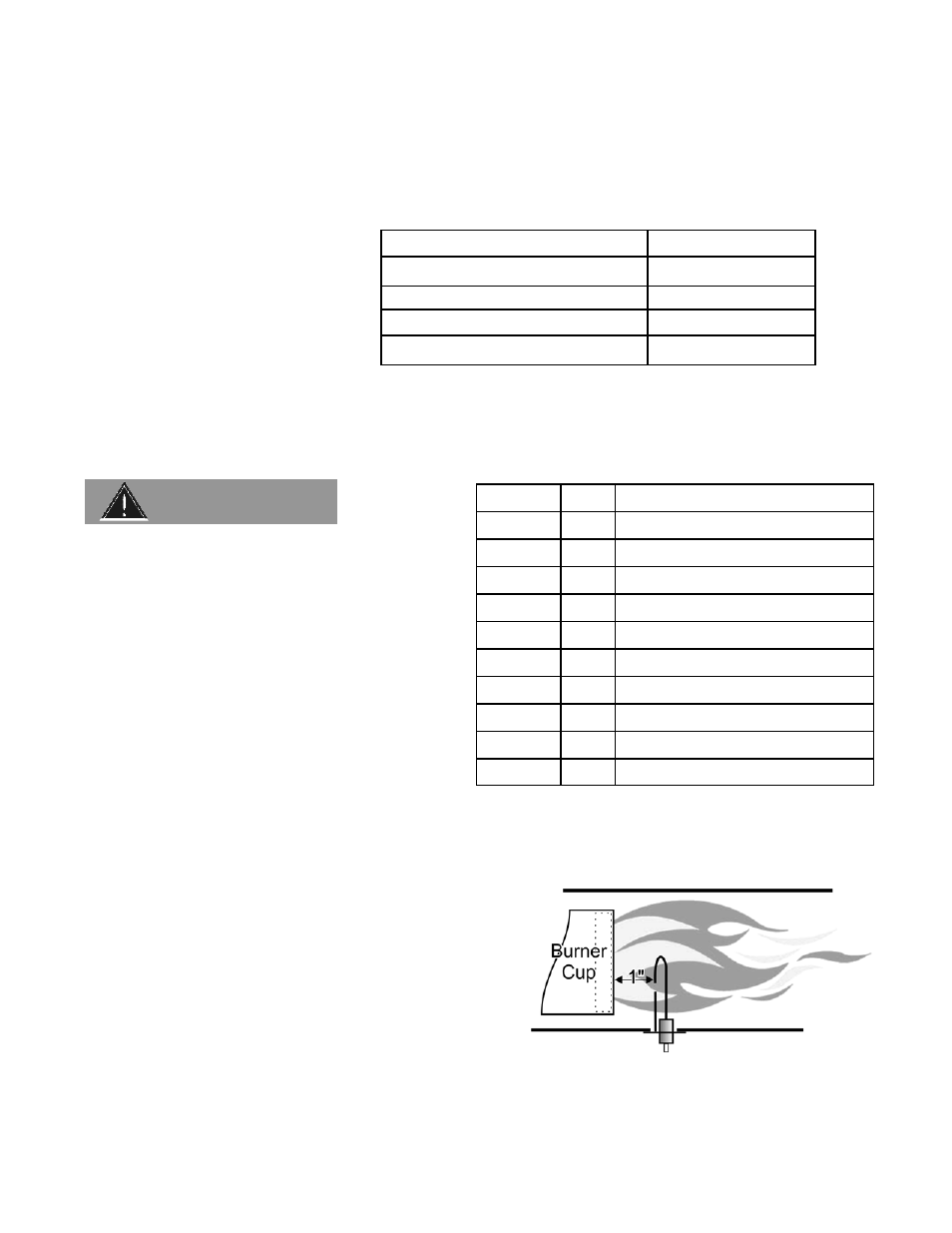

PROPER ELECTRODE LOCATION

Proper location of the electrode assembly is impor-

tant for optimum system performance. The electrode

assembly should be located so that the spark gap is

inside the flame envelope about 1 inch (2.5 cm) from

the base of the flame at the burner cup.

Electrodes should have a gap spacing of 3/16” (0.188” ± 0.031” or 4.76 mm ± 0.81 mm). If this

spacing is not correct, the assembly must be adjusted or replaced. DO NOT adjust the curved

igniter/sensor prong. Adjust/bend only the ground prong (also see next page).

Error Mode

LED Indication

Internal Control Failure

Steady on

Air Flow Fault

1 flash

Flame with No Call for heat

2 flashes

Ignition Lockout

3 flashes

WARNING

TERMINAL

TH Thermostat

Input

PSW

Pressure Switch Input

V1

Valve Power (MV)

IND

Inducer Blower Output

L1

120/240 VAC Input (Hot)

24 VAC

24 VAC Supply to Processor

V2 Valve

(MV)

GND

Valve & System Ground

Spark

Spark & Local Flame Sense

NC

Alarm (Not used)

DESIGNATION

SPADE

1/4”

1/4”

1/8”

1/4”

-

1/4”

1/4”

1/8”

1/8”

1/4”