S&S Cycle Crankcases for Harley-Davidson 2007–Up Touring Models With Twin Cam 96/103 Engines User Manual

Page 3

Hardware Identification and Installation

NOTES

• When installing hardware, be careful not to cross-thread fittings or

damage threads. Damage caused by improper installation of hardware

will not be covered under warranty.

• To prevent galling, apply anti-seize compound, pipe sealant, or PTFE tape

to threads of all steel fittings prior to installation in crankcase.

• If PTFE tape is used, loose tape must not enter crankcase or oil passages.

Do not apply tape to first 2-3 threads that screw into hole. If fittings are

removed or replaced be sure no tape shreds remain in holes. Tape shred

could block oil passages causing restriction of oil flow.

CAUTION

Restricted oil flow may result in extensive engine damage not

covered under warranty.

4. Piston Jet Installation

a. Apply a thin film of clean engine oil to new o-ring.

b. Seat o-ring in groove of piston jet mounting flange.

c. With pinhole in the jet pointing upward, install using two T20

TORX screws. Apply Loctite® 243 Blue, then tighten to 20-30 in-lbs.

CAUTION

Piston jets must be installed using the correct o-ring. Leaving out

a piston jet o-ring, installing too small of an o-ring, or pinching

an o-ring at assembly will cause oil to by-pass the jet, resulting in

low oil pressure.

NOTE: Always use a new o-rings when re-installing jets.

5. Transmission Case Drilling

NOTE: If an S&S engine or crankcase is to be installed in a motorcycle, which

has had a catastrophic engine failure, or if for any reason it is suspected

that debris or contaminants have been introduced into the oiling system,

the oil pan must be thoroughly cleaned or replaced. In order to ensure that

all debris is removed from the oil pan, the baffle must be removed. In 2009

and later models, and in current production replacement oil pans for earlier

models, the baffle is welded into the oil pan and is difficult to remove. It is

recommended that oil pans with welded-in baffles be replaced.

Harley-Davidson® replacement oil pan part number for touring bikes is

62489-99A.

CAUTION

Failure to remove debris or contaminants from the oil pan may

result in serious damage to the engine.

These instructions assume that the engine has been installed, and that

the inner primary cover and oil pan have been removed. However,

transmission case drilling can be done before engine is installed. Tool

Kit 530-0006 is recommended for easy and professional drilling and

tapping of vent and return fittings.

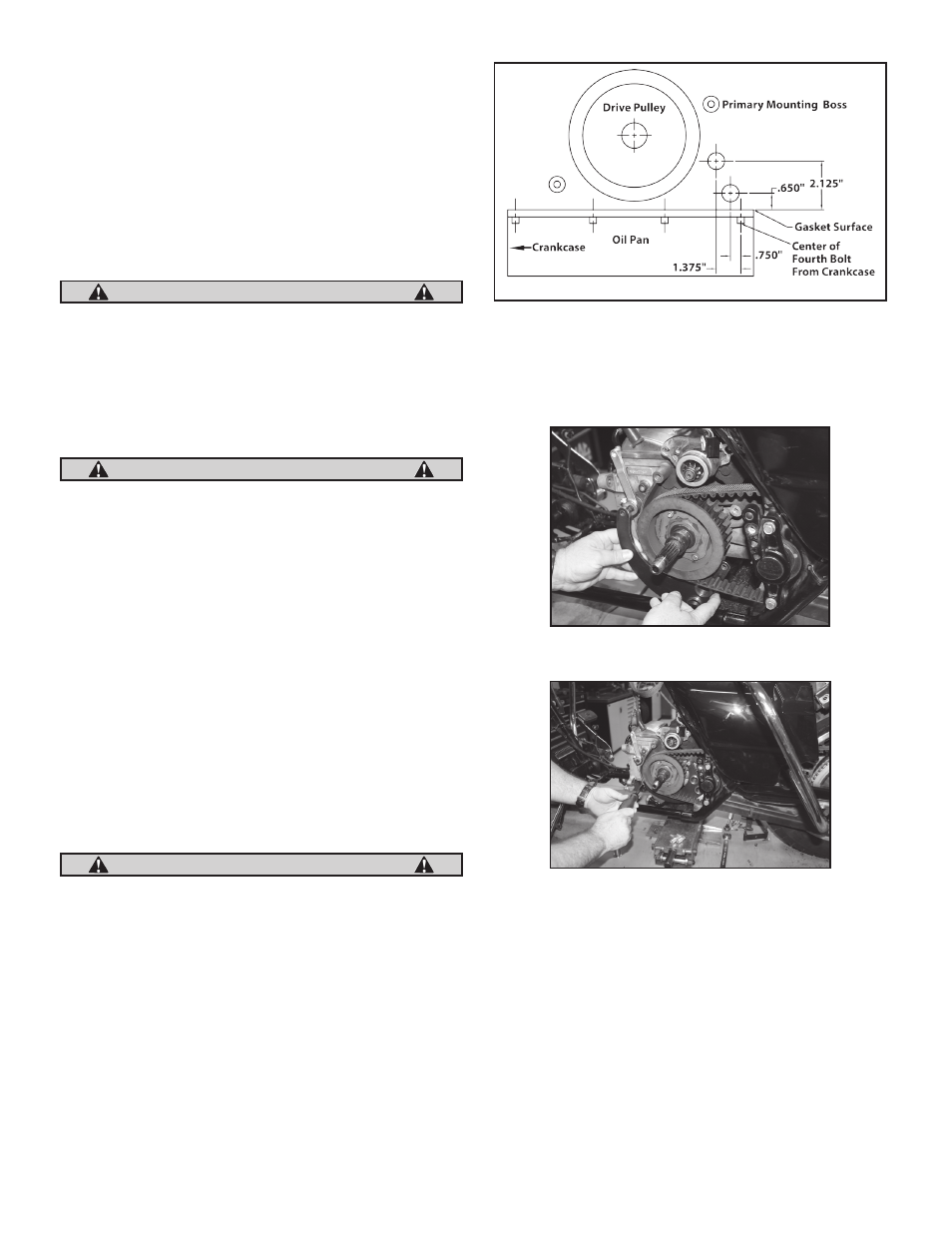

If Tool Kit 530-0006 is not available, a 9/16" drill bit and a 3/8-18 NPT

tap must be obtained. Refer to dimensions shown in Figure 1 to

determine the locations of the vent and return fitting holes. Once the

holes are drilled and tapped, the rest of the installation is the same.

a. Clean areas of drilling, gasket surfaces etc

b. Install Drill jig as shown in

Picture 1, above left

with two 5/16-18

fasteners, snug fasteners enough to hold jig securely,

see Picture

2, above right.

c. Lubricate jig bushing hole and 9/16" drill with engine oil, install drill

bushing into either hole in drill jig and drill hole. Repeat for second

hole.

See Pictures 3 & 4, next page .

d. Remove Drill jig and de-burr both holes inside and out.

See Picture

5, next page

e. Mask pipe tap so .770" of thread is exposed, this marks the depth

you want to tap the two holes

f. Lubricate pipe tap with thread cutting oil or engine oil.

g. Re-install drill jig. Using a 5/8" 12pt socket, guide the tap into the drill

jig bushing and start the tap a couple of turns in each hole, be sure

to tap far enough so that you will be able to re-start the tap to finish

the holes.

See Picture 6,next page.

h. Remove drill jig. Finish tapping each hole to the 0.770" depth

marked by the masking tape.

See Picture 7, next page.

De-burr

and clean both holes inside and out with compressed air and a

solvent such as brake cleaner.

3

Picture 1

Figure 1

Picture 2