Caution – S&S Cycle Oil Pump for T-Series Engines & Harley-Davidson Twin Cam 88 Engines User Manual

Page 2

Be sure that you disconnect the negative battery cable before doing any work on your motorcycle. This will prevent it from

accidentally starting during the installation.

NOTE: You will need to remove the pushrods and lifters and any of the oil pump components in your cases before starting the

installation procedure.

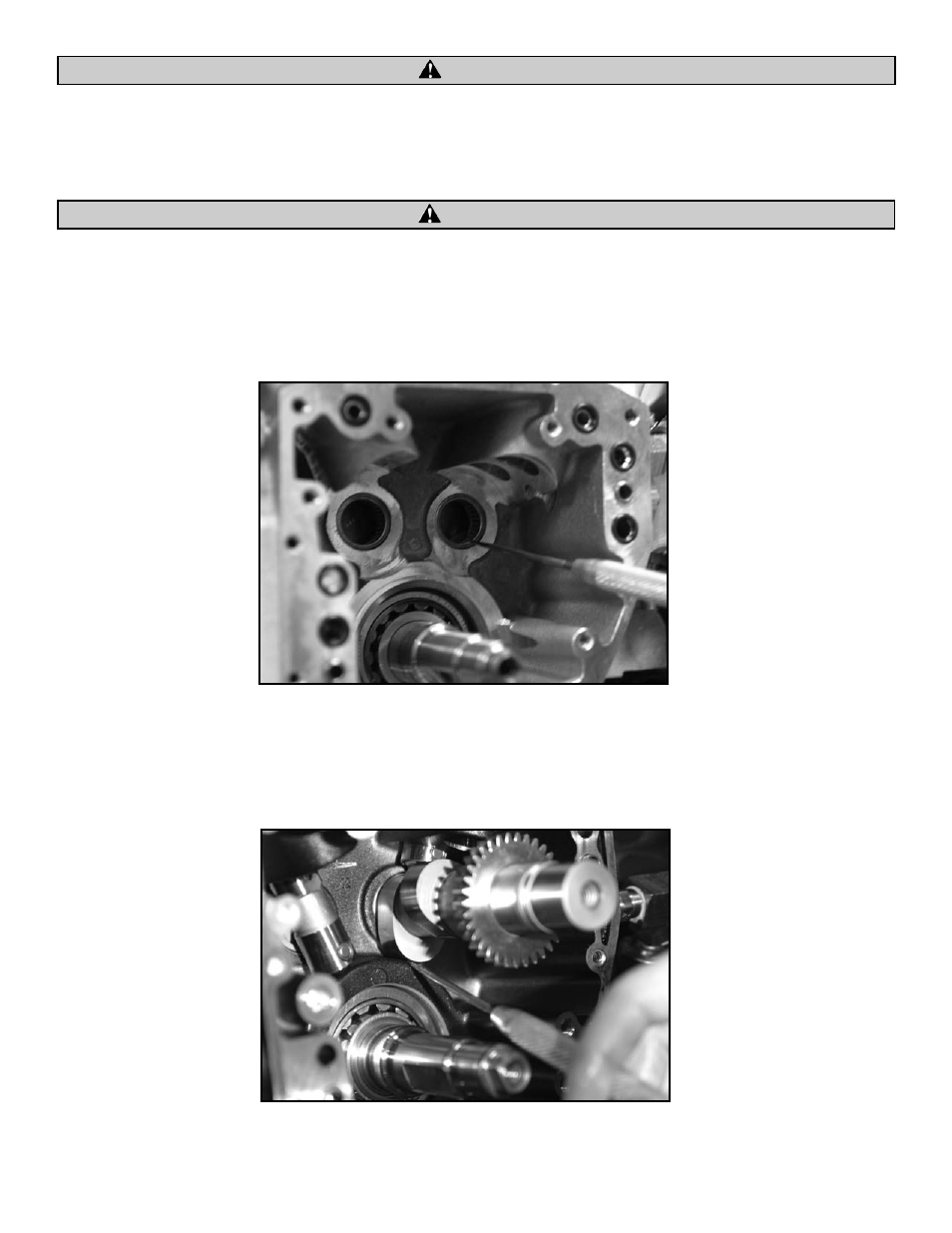

Check pinion shaft run out. Indicate end of pinion shaft at cam support plate bushing surface and rotate engine; reading must

be .003” or less total indicated reading (TIR). If reading is greater than .003” TIR the crankshaft must be repaired or replaced to

correct excess runout before installing gear drive cams. Failure to correct excess runout may lead to engine damage not covered

under S&S warranty.

The first step is to inspect the existing needle bearings and ensure they look and feel okay. They should roll freely and feel smooth with

no excessive play. Make sure that you clean the S&S

®

oil pump parts and crankcase gasket surface before starting.

Check the cam lobe to case clearance—especially in stock cases—to make sure there will be no interference. S&S

®

recommends a

minimum of .060” clearance between the lobe and the case. Be advised that installing a significantly larger cam than stock may also

result in a clearance issue between the rocker arm and rocker box—be sure to check this area before starting the motorcycle. Refer

to charts 1 and 2 for more fitment information.

2

Photo 1

Photo 2

CAUTION

CAUTION