Valve spring installation, Caution, Warning – S&S Cycle 106 Stroker Hot Set Up Kit For Victory Freedom Engines User Manual

Page 6

VALVE SPRING INSTALLATION

S&S

®

valve spring and collar kit allows cam lifts up to .495”. This kit is designed for use with stock length 7 mm diameter valves and

accepts stock style valve guides and valve guide seals. Installation of the 49-0115 spring kit does not usually require modification for

OEM heads. Kit 49-0115 spring pressures are as follows at 1.550” Installed Height: Closed valve - 75 lbf; .495” lift - 175 lbf.

Mixing of valves, springs or collars between Stock Victory

®

and S&S high-lift kit can cause extensive engine damage not covered

under warranty.

1- If cylinder heads/valves are to be reconditioned, proceed at this time according to standard procedure. Refer to Victory service

manual as necessary.

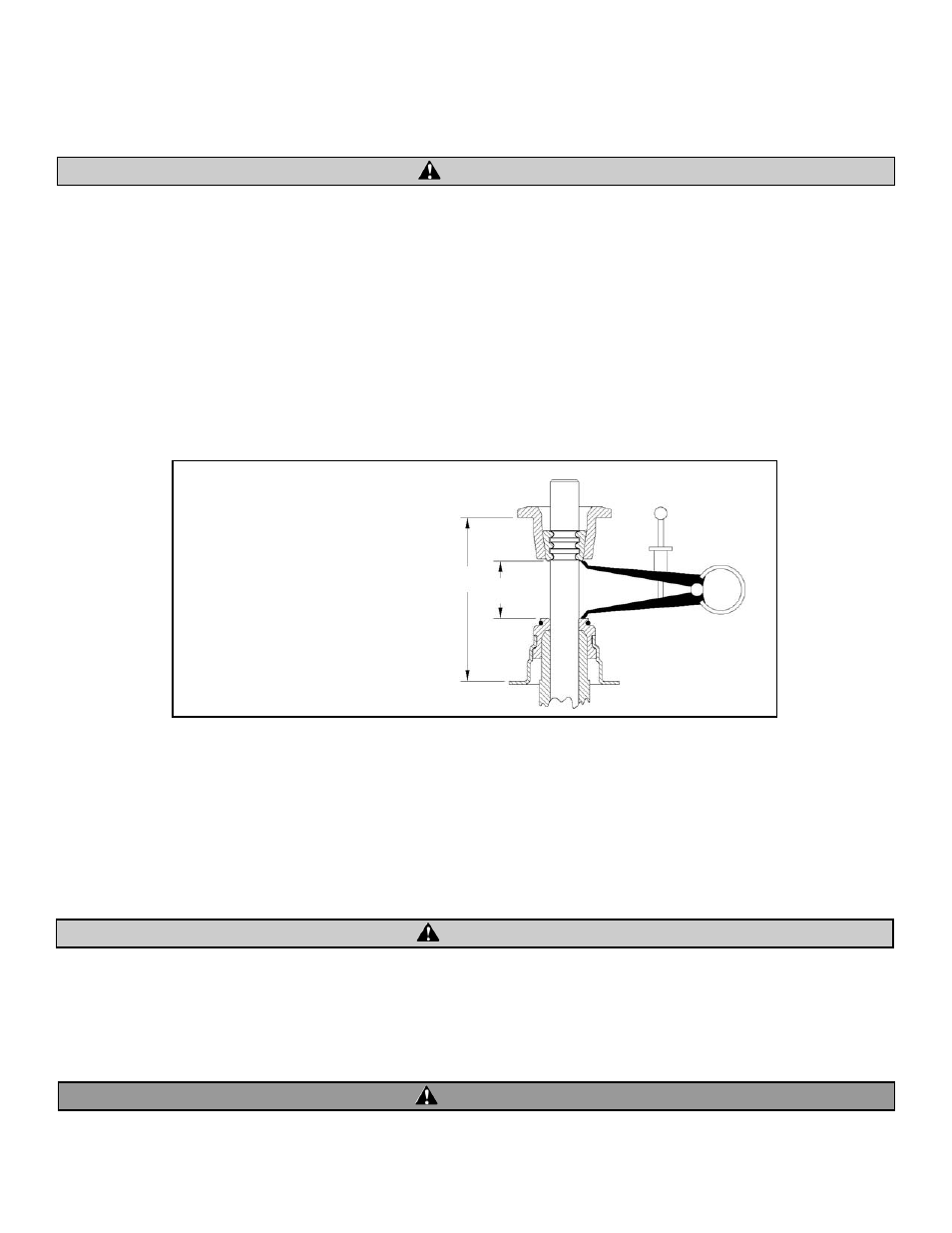

2- Using following procedure, determine installed spring height and clearance between top collar and valve guide seal.

A-

Lubricate valve stem and install valve in guide.

B-

Install stock bottom collar w/integral valve seal, S&S top collar, and S&S valve keepers. Pull top collar tightly against keepers

to seat keepers in collar.

C-

While holding valve firmly against seat in closed position, measure installed spring height (distance between lower valve

spring seating surface and outside step of top collar). See Figure A, Dimension A. Record measurement.

D- Measure distance between top collar keepers and top of valve seal (if applicable). See Figure A, Dimension B. Distance must

be at least .030” greater than valve lift of cam to be used.

E-

Repeat Steps A-D for remaining valves and record all measurements. Be sure to keep track of all parts during assembly and

disassembly to assure they are installed in same location and with same valves clearances in which they were measured.

NOTE: For race and similar applications, experienced engine builders may elect to shim valve spring assembly to installed height less

than 1.550” if cam with less than .495” valve lift is used. In such cases, installed height should not be less than 1.055” + valve lift ±.010.”

For example, with .400 lift cam, installed height could be shimmed to 1.055” + .400”, or 1.455” ± .010”. In such cases, spring pressure

and valvetrain wear will increase significantly. Engine builder assumes all responsibility for installing springs at height other than

1.550” ± .010”.

G Installing springs at height less than recommended dimension will cause rapid spring fatigue resulting in possible engine damage.

Engine should be frequently disassembled for spring tension measurement.

G Installing springs at height above recommended dimension will decrease spring tension resulting in possible valve float and

engine damage.

G Failure to establish required clearances may cause valve seal failure and other, more extensive engine damage not covered under

warranty.

Valve spring assembly is under considerable tension when compressed and is potentially dangerous. Wear eye protection and

take due caution when checking for coil bind and during installation. After assembly, carefully strike tip of valve stem with

plastic hammer to insure that keepers are seated. Direct spring assembly away from face and body during this procedure.

CAUTION

Figure A

A

B

Dimension A:

Installed spring height must be

adjusted to 1.550" ± .010".

Dimension B:

Must be .030" greater than valve

lift for camshaft to be used.

CAUTION

6

WARNING