S&S Cycle Prostock Racing Camshafts Part 33-5085 User Manual

Page 4

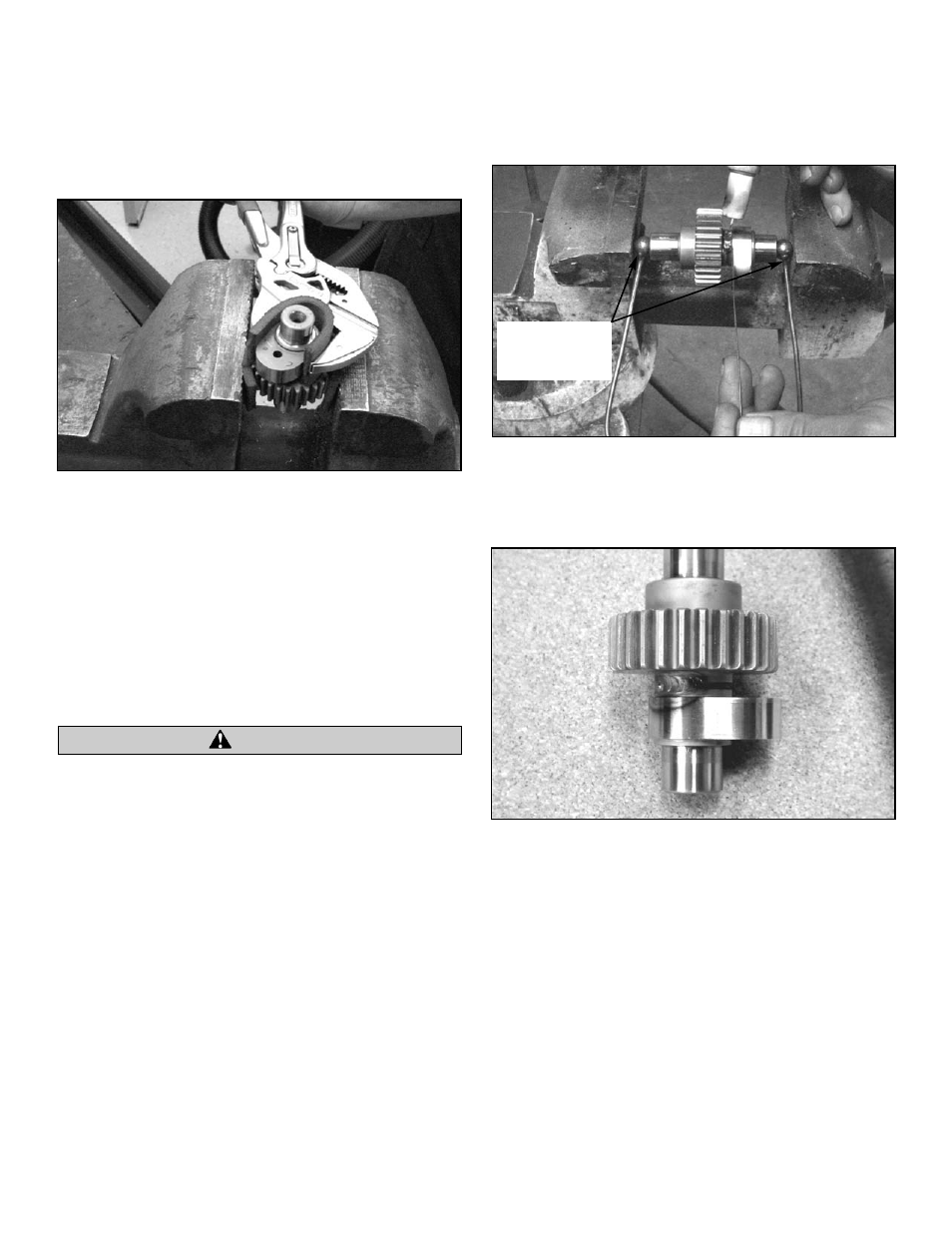

2.

For additional information, Contact Advanced

Racing Technology, Inc. Route 360 Box 247,

Burgess, VA 22432 Ph. 804-453-3357. An

alternative trial and error method is to use

heavy leather strips to protect the cam and

lobe while moving the lobe with an adjustable

wrench. See Picture 6.

3. Place cam back into engine and check the

adjustment. Repeat the degree and lobe

adjusting procedure until each valve opening

is at the desired degree. After the degree

procedure has been completed on both

cylinders, and all four lobes have been set to

their final position, the camshafts are ready to

be welded.

4. Welding Cam Lobes Into Position

Cam lobes must be welded to the camshaft before use.

NOTE: Clean all parts thoroughly with an evaporative

solvent before welding. Use care not to disturb lobe

position.

A. Locate the camshaft in a suitable fixture that will

allow easy access for the welder, and prevent

arcing to the cam lobe surface. A homemade jig

and fixture consisting of a vice, ball bearings and

wire works well. See Picture 7.

B. Weld cam lobes 180 degrees around the base circle

using the TIG process. Stainless steel alloy filler rod

is recommended. See Picture 8.

NOTE: The welding operation should only be performed

by an experienced TIG welder. Be careful not to arc to or

otherwise damage cam bearing or lobe surfaces. Welded

cams cannot be returned or exchanged.

4

Picture 6

CAUTION

Picture 7

Picture 8

Place jig in vice

screw holes for

added stability.