S&S Cycle Prostock Racing Camshafts Part 33-5085 User Manual

Page 3

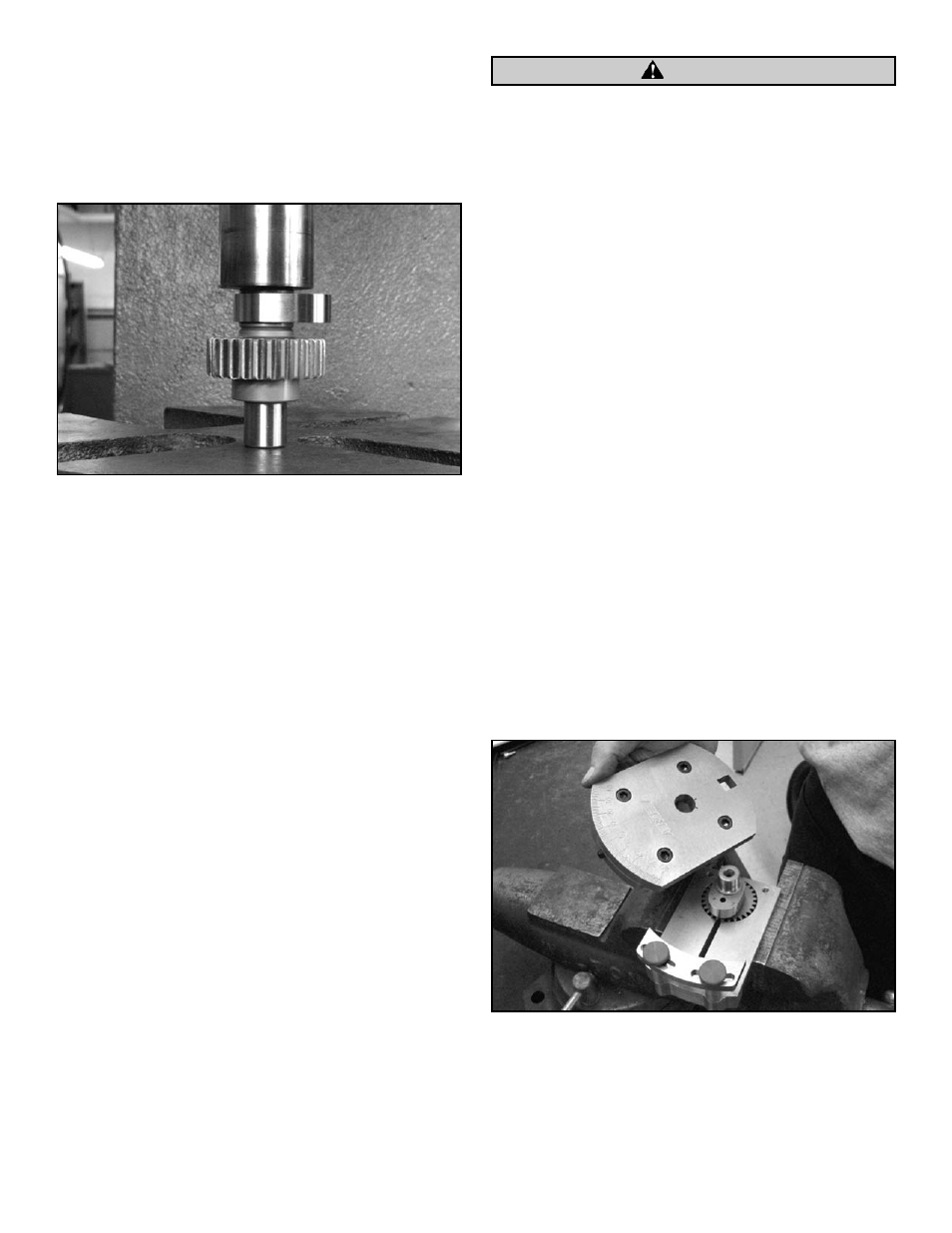

B. After establishing the initial lobe positions,

remove cams from cam cover, then use a suitable

press and mandrel to press the lobe onto the shaft.

It is a light press fit - an arbor press works well.

Press the lobe down completely until it is fully

seated with no gap between the lobe and the

gear shoulder. See Picture 4.

3. Degree Cam Lobes and Adjusting Lobe Positions

After the initial positioning and pressing on of the

lobes, per section “C” position the cams in the engine

and perform the degree operation.

A cam degree worksheet has been included for

convenience.

NOTES:

●

Installation of S&S

®

Prostock cams should only be

attempted by an experienced engine builder

●

It is up to the installing mechanic to determine the

desired intake or exhaust valve opening degree point

for all lobes. See the Notes section of the included cam

degree worksheet for formulas to assist in calculations.

●

Use .053” lift off of the base circle as the degree

reference point.

●

S&S recommends that cams be set-up and used in the

same engine case.

●

Use only light checking springs to check valve train

clearances before cam lobes are welded.

●

Do not install heavy valve springs until the cams

have been welded.

●

It is the installing mechanic’s responsibility to

ensure there will be no piston to valve or valve to

valve contact.

A. Degree Cam Lobes- The procedure is repeated for

each cylinder.

1. Position a degree wheel on the crankshaft and

locate the top dead center point using a

positive piston stop. After locating TDC, set the

degree wheel so that the pointer is set to 0.

2. For either the intake or exhaust lobe, rotate

the crankshaft and note the degree mark

pointed to on the wheel at .053” lobe lift on

the opening side of the lobe.

3. The difference in degrees between the

indicated opening point at .053” lift and the

desired opening point at .053 lift is how many

degrees the lobe needs to be moved, either

forward or back to place the lobe at the

desired opening point. (Opening point for

each lobe is determined by installing

mechanic, see NOTE.)

B. Adjusting Lobe Positions

1.

After determining how many degrees the lobe

must be moved either forward or back,

remove the cam from the engine and adjust

the position of the the lobe. The preferred

method is to use a special tool such as the

A.R.T. Sportster

®

and XR 750 Cam Lobe Degree

Tool. See Picture 5.

3

Picture 4

Picture 5

CAUTION