S&S Cycle California X-Wedge Engines User Manual

Page 14

14

4- Install Evaporative System

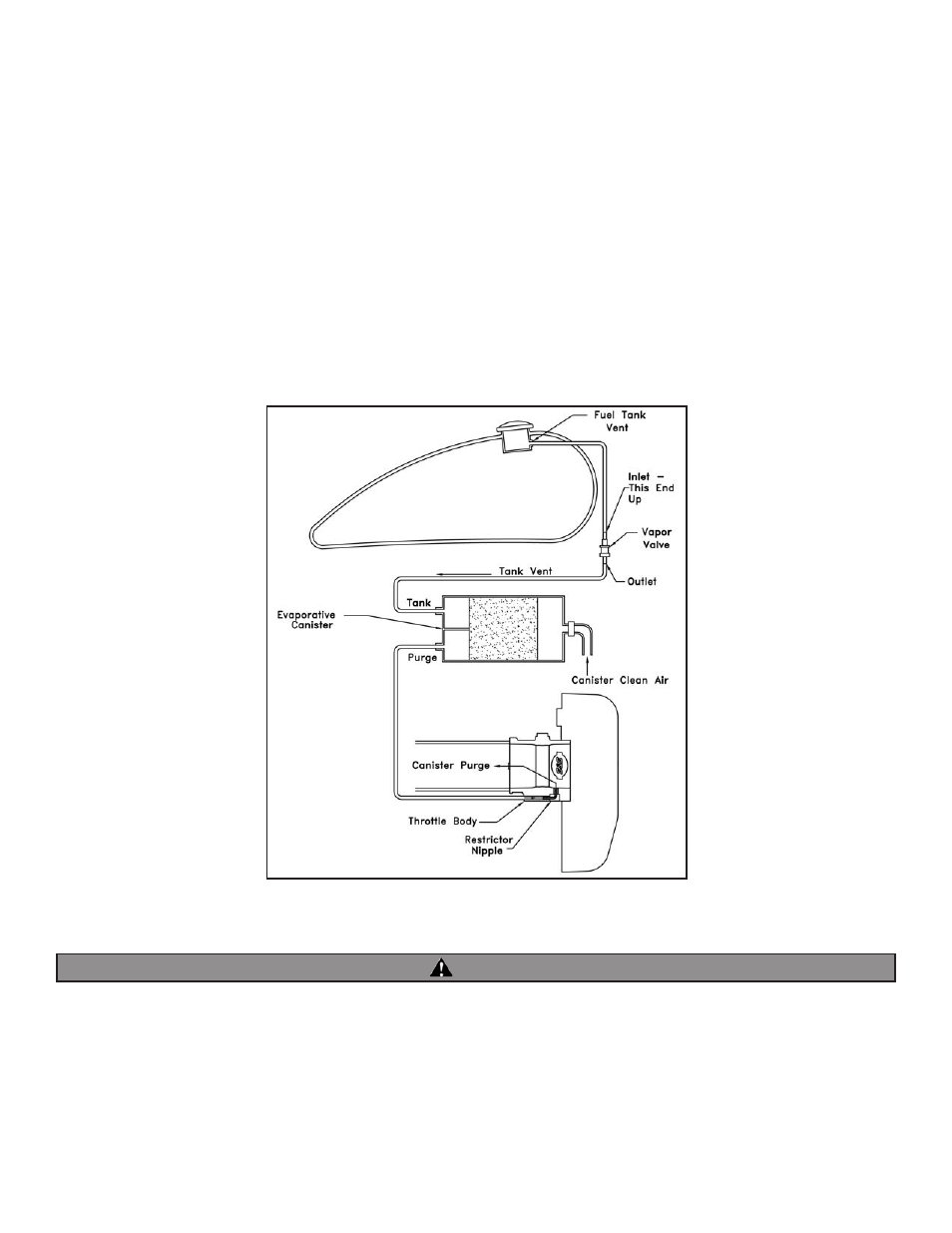

The evaporative system must be installed in its entirety following the instructions and diagram provided below.

1- Determine a location for the evaporative canister that allows the vapor lines to be connected and install the evaporative canister onto the

motorcycle.

2- Determine the routing of the evaporative vent hose connecting from the fuel tank vent, through the vapor valve, and to the fitting on the

canister labeled “tank”. The vapor valve must be installed in a vertical position with the smaller end pointing up as shown in “Evaporative Hose

Routing Diagram”. Ensure the hose will not come in contact with any hot or moving parts.

NOTE: The vapor valve must be installed in a vertical orientation with the smaller diameter end pointing up as shown in the “Evaporative Hose

Routing Diagram”.

3- After the evaporative vent hose routing has been determined, cut the hose to length and make the connections.

4- Determine the routing of the evaporative purge hose that connects the fitting labeled “purge” on the canister to the 90 degree purge fitting on

the throttle body as shown in the "Evaporative Hose Routing Diagram”. Ensure the hose will not come in contact with any hot or moving parts.

5- After determining the evaporative purge hose routing, cut the hose to length and make the connections.

6- Secure the evaporative hoses to the motorcycle using proper wire ties so they will not come in contact with any hot or moving parts.

5- Fuel System

Fuel hose must be clamped securely with proper clamps and can not contact any hot surfaces where it could melt or catch fire, causing

serious injury or death.

The X-Wedge engine requires a fuel supply of 58 psi to the fuel injectors. A fuel pump and regulator assembly is available from S&S® (PN 55-5089)

that is designed for being mounted inside the fuel tank. Other pumps may be used as long as the supply is regulated to 58 psi and it provides a

minimum supply of 45 L/hr. It is recommended a fuel filter that filters to 10 um be used.

Connections

Fuel is supplied to both fuel injectors from a tee located in the fuel hose between the injectors. The engine is delivered with an extra length of fuel

hose connected to the tee for connection to the fuel pump. This hose may be trimmed to fit your application if needed. Position fuel hose to avoid

contact with hot cylinders or other engine parts.

WARNING

Evaporative Hose Routing