S&S Cycle TÜV Long Block Assembly User Manual

Page 4

4

2.

Install opening side throttle cable barrel fitting and

throttle cable in throttle linkage and appropriate side of

throttle cable housing bracket. Opening side cable

housing outside diameter is smaller and measures .190"

(4.826mm).

3.

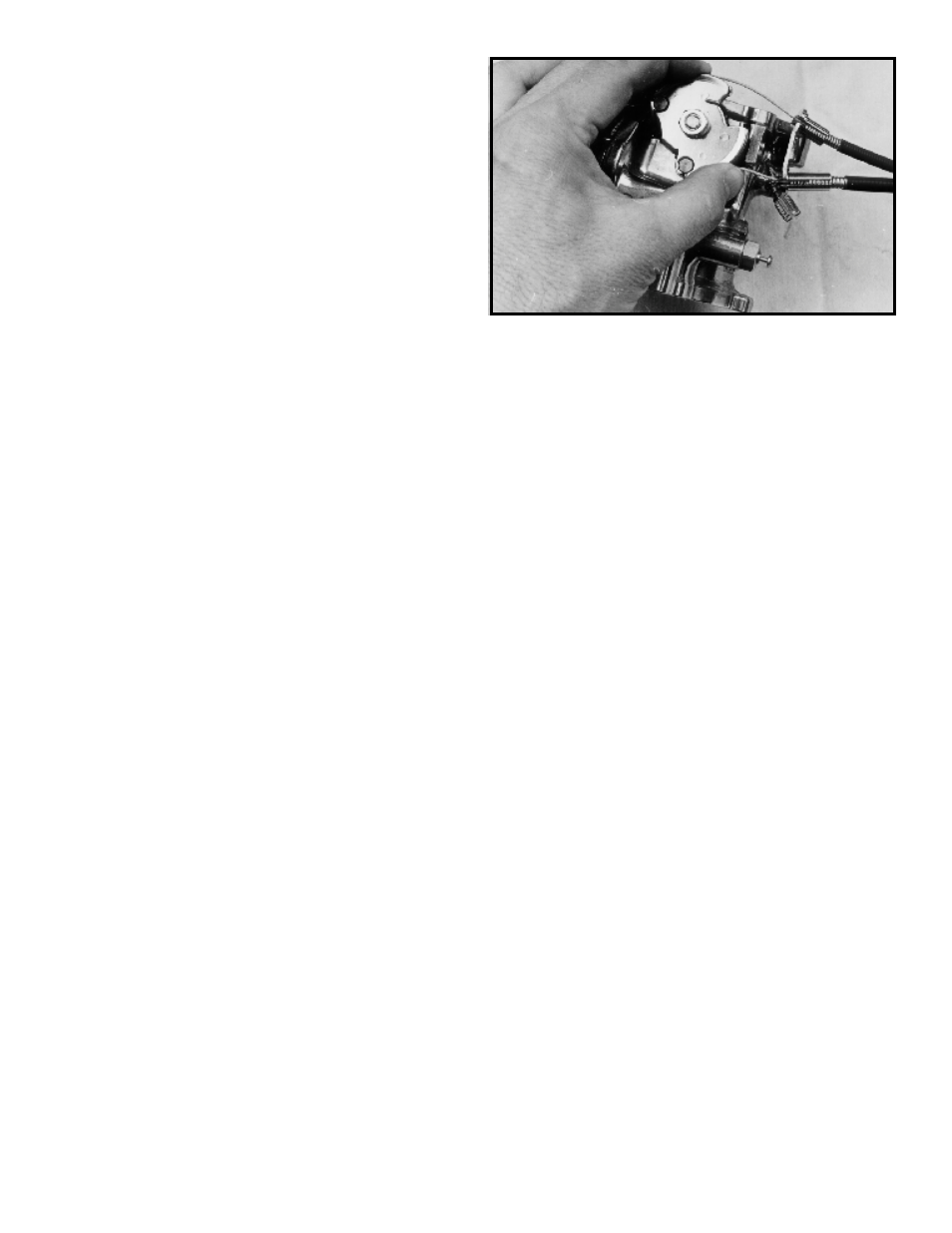

Repeat step 2 for closing side throttle cable. Closing

side cable has a spring around inner cable wire. See

Picture 2.

4.

Reinstall throttle cable housing bracket on carburetor.

B.

Turn throttle cable adjusters to remove excessive freeplay.

Test throttle to be sure it opens and closes freely; throttle

should snap shut when released. Turn handlebars to

extreme left and open and close throttle, then turn bars to

extreme right and repeat. If throttle binds, loosen cable

adjusters to put more freeplay in cables. Tighten adjusting

screw locknuts after final adjustments are made.

NOTE - Throttle grip assembly must be assembled correctly and work

freely to prevent possible sticking during operation. Cable routing

must be free of tight bends to minimize cable to cable housing friction.

Throttle must not bind and must snap shut to fully closed position

when released.

WARNING - Incorrect cable adjustment may cause throttle to

stick open, causing loss of control of motorcycle, serious injury

or death.

C.

Slip hose clamp over end of fuel line with 90

°

bend. Apply

thin coating of oil to fuel inlet fitting on carburetor and slip end

of fuel line with 90

°

bend over fitting. Position fuel line in such

a way as to avoid contact with hot cylinders or other engine

parts. Tighten hose clamp. Slip protective fuel line covering

over fuel line and position to prevent direct contact between

fuel line and cylinders or other engine parts. Connect fuel

line to gas tank petcock using hose clamp provided.

CAUTION - Engines vented through heads must not have

breather bosses plugged as oil leakage and damage may occur.

WARNING - Fuel line must be clamped securely and not contact

any hot surfaces such as exhaust pipes where it could melt or

catch fire, causing serious injury or death.

7.

Final assembly and checks.

A.

Connect vacuum petcock hose if equipped.

B.

Check fuel line routing and connections.

C.

Test throttle to be sure it opens and closes freely. Turn

handlebars to extreme left and open and close throttle, then

turn bars to extreme right. Throttle must snap closed in all

positions.

D.

Reassemble any remaining components.

E.

Check fuel inlet fitting and fuel line connections for leaks.

NOTE - Fuel needle and seat assembly must completely shut off fuel

supply entering bowl. Fuel inlet fittings and fuel line connections must

not leak.

CAUTION - Gasoline leaking past inlet needle may flood engine

causing fire hazard or damage to components.

WARNING - Gasoline leaks at inlet o-rings, fuel line connections,

or inlet needle may flood engine and overflow into surrounding

area creating fire hazard.

F.

Fill gas tank.

G.

See S&S TÜV Long Block Owner’s Manual for engine

starting instructions.

8.

Troubleshooting Tips

A.

Engine will not start:

1.

Fuel tank empty or petcock in closed position.

2.

Weak or no spark - discharged battery, damaged

ignition module or coil.

3.

Spark plug gap too wide.

4.

Improper ignition timing.

B.

Engine will not run at steady speed or rpm:

1.

Restriction in fuel supply system - gas tank vent

plugged, needle and seat not working properly.

2.

Faulty ignition system - fouled plugs, defective coil or

electronic module, improper ignition timing.

NOTE - Bowl vent hole passageway leads to cavity above fuel in

bowl and is designed to equalize bowl pressure and atmospheric

pressure. If high or low bowl pressure relative to atmospheric pressure

develops, engine may run erratically.

GENERAL INFORMATION NOTES:

●

Carburetor body has six drilled passages that are permanently

sealed with drive plugs.

CAUTION - Removal of these plugs may cause irreversible

damage to carburetor not covered under warranty.

●

When motorcycle is not running, the petcock should always be

turned off to prevent possible fuel leakage past needle and seat.

●

Throttle plate, part #11-2055 or #11-2355, and throttle shaft, part

#11-2383 or #11-2483, should be checked annually for signs of wear

and replaced if necessary. If carb body throttle shaft bushings are

worn, carb must be returned to S&S for repair. If throttle plate is

removed, be sure to reinstall it correctly. Beveled edges of plate must

fit flat against inside of carb bore.

●

If accelerator pump cap is removed, lift cap slowly so small spring,

part #11-2374, checkballs, part #11-2272, and o-rings part #11-2371

are not lost.

CONCLUSION

Complete remainder of installation according to the applicable H-D

Service Manual. Refer to the S&S TÜV Long Block Owner’s Manual

for important information on breaking in the engine.

CAUTION - Failure to break in engine according to correct

procedure may result in serious damage to engine not repairable

under warranty.

Picture 2