S&S Cycle 49-State EPA Certified Engine User Manual

Page 6

6

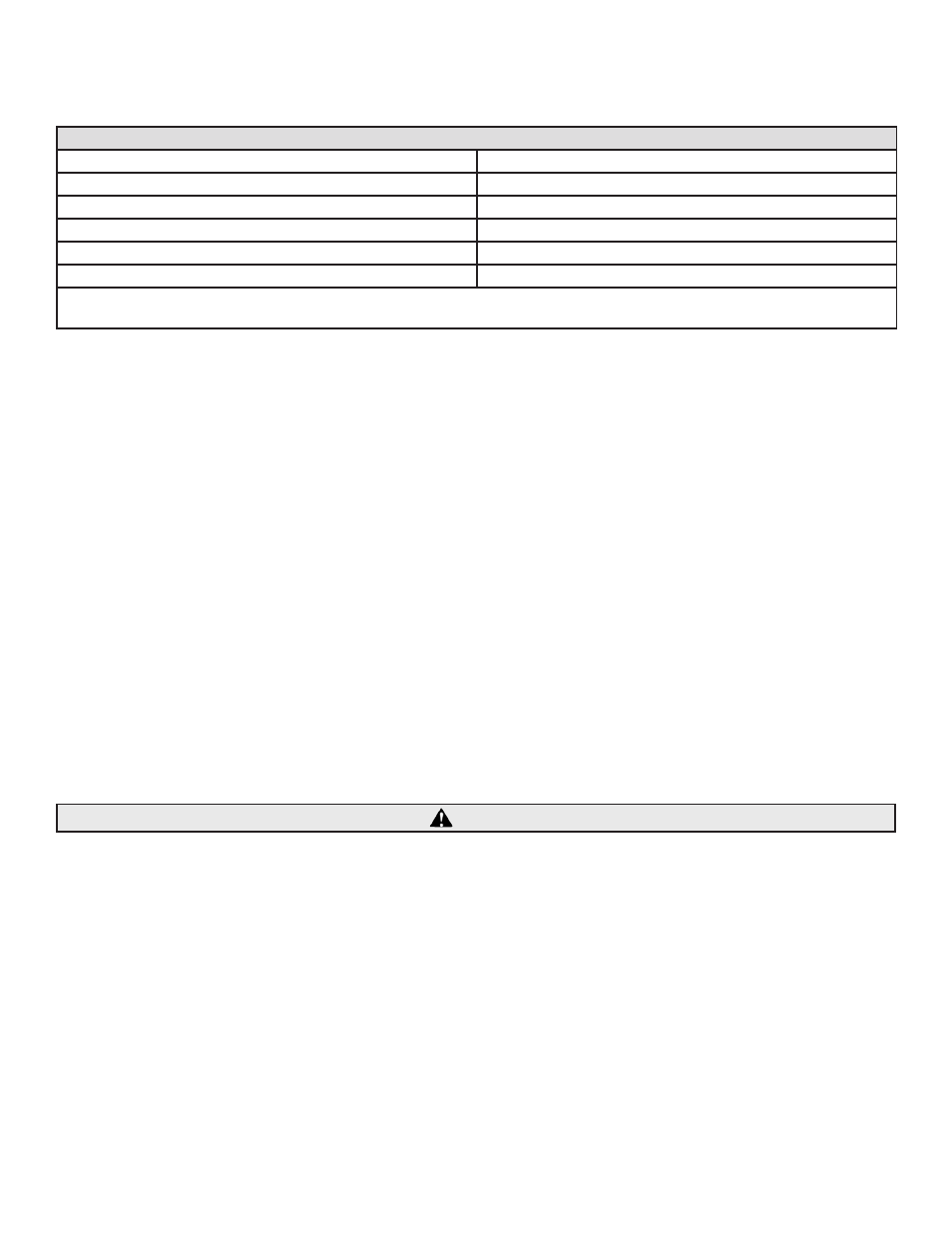

Recommended Engine Oils

Ambient Temperature Range

Viscosity Grade

Below 40°F (4°C) (Winter Only)

SAE 10W40

40°F (4°C) to 100°F (38°C)

SAE 15W50 or 20W50

50°F (10°C) to Above 100°F (38°C)

SAE 25W60

60°F (16°C) to 100°F (38°C)

SAE 50

80°F (27°C) to Above 100°F (38°C)

SAE 60

Notes: • Use only API SG or SH rated oil. • S&S recommends regular oil changes every 1,000 miles (1600 kilometers) when using petroleum-based

oil not specifically formulated for motorcycles.

NOTE: S&S® recommends using Mobil 1 V-Twin synthetic oil. S&S recommends regular oil changes every 1,000 miles (1,600 kilometers) when using

petroleum-based oil not specifically formulated for motorcycles.

Checking, Adding & Changing Engine Oil

See the motorcycle owner’s manual for information on how to check, add, and change the oil and filter.

Hydraulic Lifter Oil Filter Screen

The access screw for this screen is located on the right side of the crankcase, beside the rear tappet block. Carefully remove the screw to expose the

spring and filter screen. Remove the spring and filter screen from the crankcase. Clean or replace the screen. Reinstall the screen (open end down),

spring, and screw.

Gas Tank Fuel Stainer & In-Line

Inspect and clean the gas tank fuel strainer according to the motorcycle owner’s manual. If an in-line filter is used (recommended), it should be

replaced or cleaned according to manufacturer’s specifications.

Carburetor

The carburetor has been specifically set up for emissions control. All jets are fixed at the factory.

Idle Speed Adjustment

1- Operate motorcycle until engine is warmed up (typically 15 minutes).

2- The idle speed adjustment screw is located on top of the carburetor just under the throttle cable guide. Use a long, blade-type screwdriver to

adjust the idle speed to 1,050 RPM.

Air Cleaner Element

The air cleaner element comes pre-oiled and does not need to be oiled before use. The element should be replaced every 5,000 miles (8,000

kilometers). If the element is torn, punctured, or has excessive oil build-up replace the element.

A damaged, torn, punctured, or crushed element may allow unfiltered air to enter the engine. In the event of a damaged air cleaner

element, replace element immediately.

Replacement

1- Remove air cleaner cover.

2- Remove element.

3- Install new element on air cleaner backplate.

4- Reinstall air cleaner cover.

Hydraulic Lifters

Hydraulic lifters are self-adjusting. They automatically adjust length to compensate for engine expansion and valve train wear, keeping the valve

train free of lash while the engine is running. When starting the engine, the valve train may be noisy until the lifters refill with oil. If the valve train

remains noisy after twenty minutes of operation, this may be an indication that one or more of the lifters is not functioning properly. Remove and

clean the hydraulic lifter oil filter screen. Consult an S&S service agent if further service is required.

Spark Plugs

Spark Plug Removal:

1- Disconnect spark plug wires from spark plugs by pulling on the molded connector boots. It may help to twist or rock the boots back and forth

slightly while pulling.

2- Unscrew spark plugs.

CAUTION

Engine Oil

Engine oil is a major factor in the performance and service life of the engine. Use the proper viscosity of oil for the ambient temperature range

anticipated before the next oil change as shown in the following table.