S&S Cycle Degree Wheel Kit PN 53-0020 User Manual

Page 3

During disassembly breather timing should be checked and

set to:

Breather valve opens at 20˚ to 25˚ ATC

Breather valve closes at 85 to 90 ABC

To check existing breather timing set degree wheel to TC 0˚ mark

with front piston at TDC. Perform checks with pushrods and cam

cover removed.

To set breather timing to above specs during engine rebuild

perform following steps:

1.

Engines 1957 to 1971 - We strongly recommend purchase of

1972 and later pump breather gear, part #26331-72, and

corresponding gear retainer lock ring, part #11002. These

parts are used in place of early pump breather gear, part

#26331-60, because slot in early gear is wider and makes

modification of pump body too difficult to obtain desired

results. To use later parts install scavenger gear, part

#26315-62, with flat side of gear facing retainer lock ring.

2.

Assemble engine to point of oil pump installation.

3.

Place degree wheel on sprocket shaft and set to TC 0˚ mark

with front piston at TDC.

4.

Turn pump gear counterclockwise until slot in gear aligns

with slot in pump body.

5.

Place .002” shim in opening and reverse gear until shim is

held tight between body and gear.

6.

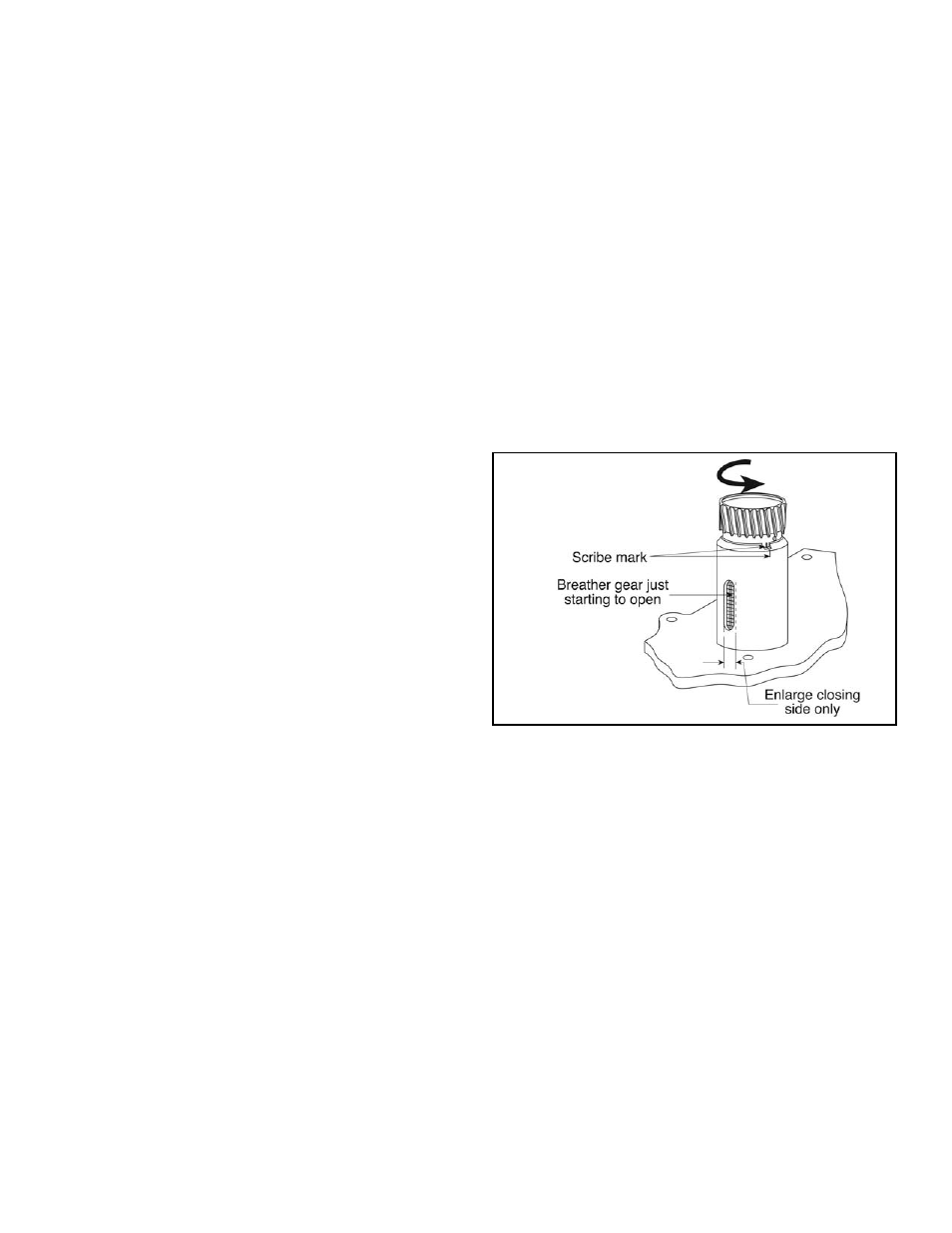

Scribe mark across pump gear sleeve and pump body at small

timing notch on top edge of body. See Figure B. Because

pump gear sleeve is very hard and difficult to scribe mark, it

may be advantageous to coat top portion of sleeve just

below teeth with Dykum

®

Blue.

7.

Install and time pump using normal assembly procedure. Do

not final tighten oil pump mounting bolts.

8.

Rotate flywheels to 25˚ ATC mark. Be sure oil pump drive

gear is firmly butted against shoulder on pinion shaft. If

scribe mark on pump gear is to left of scribe mark on body,

grind material off engine side of pump drive gear to allow it

to move farther onto shaft until scribe marks align. If scribe

mark is to right, shim between pump drive gear and

flywheel assembly until marks line up. Big twin cam thrust

washers, part #25550-36, can be used as shims, but are

marginal because they do not fit well on pinion shaft. If you

are not satisfied with fit, you may machine your own shims

like we do.

9.

Rotate flywheels to 85˚ ABC mark. Make second scribe

mark on pump gear sleeve that lines up with first scribe

mark on body.

10. Remove pump and carefully grind or file side of slot towards

cam cover in body (closing side only) until slot closes when

second scribe mark on sleeve and first mark on body line up.

11. Thoroughly clean and final assemble oil pump in crankcases.

12. Place oil pump drive gear on pinion shaft, and time pump in

normal fashion. If material was removed from flywheel side

of oil pump drive gear, it will be necessary to shim between

pump drive gear and pinion gear. Pinion gear must be flush

with or extend out slightly past splines on pinion shaft when

installed tight against pump drive gear.

13. Check clearance between pinion gear and cam cover

bushing. Clearance must be .005”. Use Plasti-gauge or

whatever method you choose to determine clearance. Shim

on outer side of pinion gear to obtain .005” clearance.

Harley-Davidson

®

shims, part #18268-48, are .015” thick each

and may be used for this purpose.

*All reference to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding Harley-Davidson

®

part

number shown.

3

Figure B