S&S Cycle Degree Wheel Kit PN 53-0020 User Manual

Page 2

General Information

Degree wheels have many uses. The more important ones

are setting ignition timing, checking crankcase breather

timing and checking cam timing.

The S&S

®

degree wheel assembly adapts to fit most any 45˚

v-twin engine by combining one or more of the special

collars supplied in each kit. Once a proper combination is

selected, the wheel is secured with a sprocket nut or with

the clamping screw on the degree wheel.

Degree Wheel Divisions and Terminology

Degree wheel references encountered are listed below.

After Top Center (ATC) = Top Center (TC) (0˚) clockwise

to 90˚

Before Bottom Center (BBC) = 90˚ ATC clockwise to

Bottom Center (BC) (0˚)

After Bottom Center (ABC) = BC (0˚) clockwise to 90˚

Before Top Center (BTC) = 90˚ ABC clockwise to TC (0˚)

Ignition and Crankcase Breather Timing Piston

Positioning

Most ignition timing and crankcase breather timing is done using

front cylinder. To use S&S degree wheel:

1.

Determine highest point of piston travel (Top Dead Center -

TDC) for front cylinder and rotate flywheels so piston is in

that position.

2.

Clamp degree wheel on sprocket shaft so pointer lines up

with with Top Center (0˚) mark. (Most S&S flywheels have a

Top Dead Center front cylinder (T/F) timing mark to indicate

highest point of front piston travel. When mark is positioned

in center of timing hole, front piston is at TDC.)

To locate TDC for rear cylinder by using front cylinder:

1.

Position front cylinder at TDC.

2.

Clamp degree wheel on sprocket shaft so pointer lines up

with with 45˚ ATC mark.

3.

Rotate flywheel assembly with degree wheel clamped in

place so pointer lines up with Top Center (0˚) mark. Rear

cylinder is now positioned at TDC.

Ignition Timing Flywheel Marks

Ignition usually occurs before piston is at TDC. All ignition timing

are positioned Before Top Center (BTC).

See the appropriate manual for timing specifications.

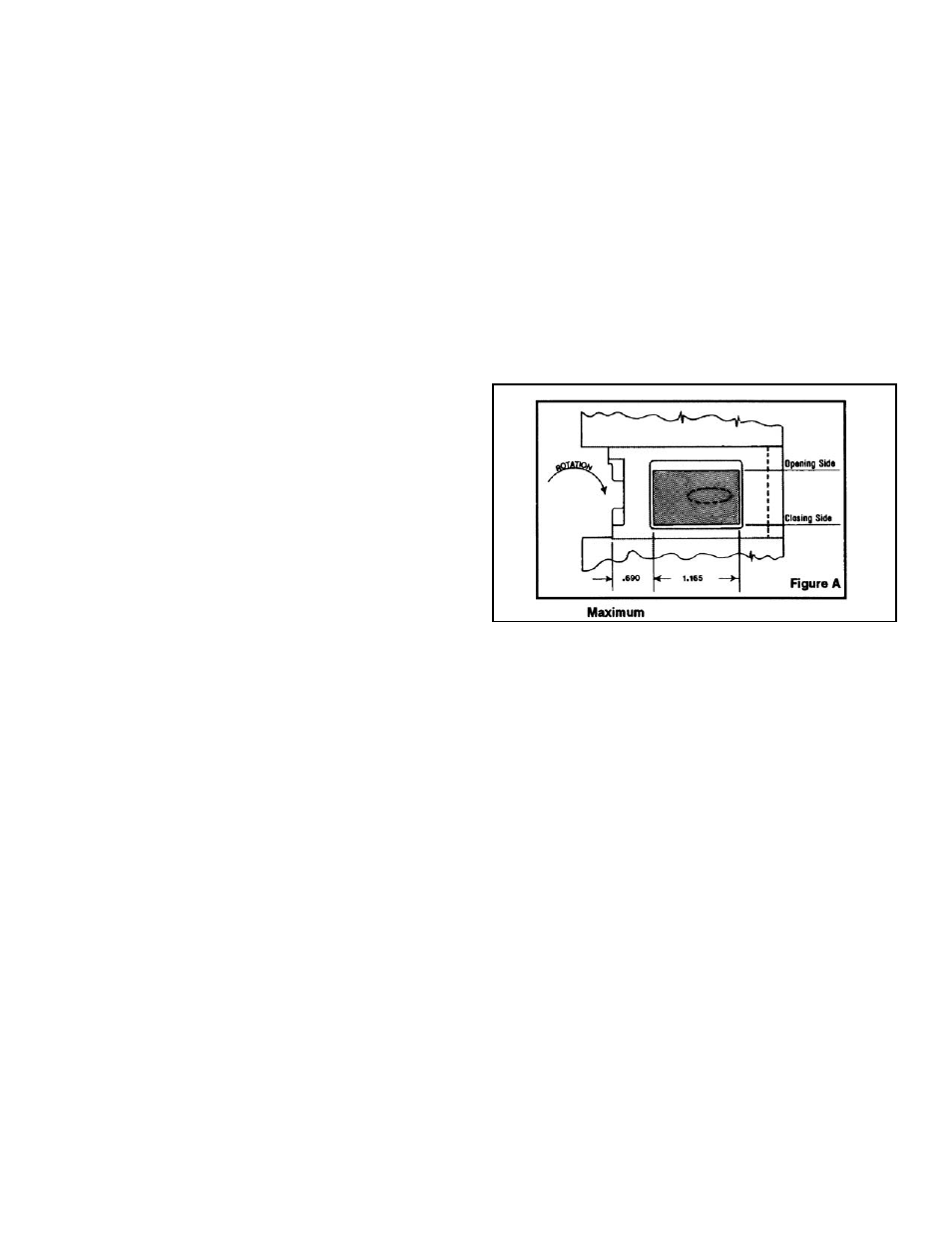

Crankcase breather timing for big twin engines

The crankcase breather timing on all big twins should be

checked. Engines prior to 1980 require checking especially so,

because the normal breather opening is a rough cast elliptical

hole. This hole must be filed or ground to a rectangular

shape: width and length should not exceed original

dimensions. On all engines opening and closing sides and

.690” dimension (See Figure A) should then be checked

against specifications listed and filed if necessary.

This data is presented to maximize crankcase breathing

efficiency which will help an engine perform better and cleaner.

Set degree wheel to TC 0˚ mark with front piston at TDC.

Perform checks before engine is disassembled with pushrods

and cam cover removed.

Maximum

Breather opens 10 degrees BTC

Breather closes 75 degrees ABC

Minimum

Breather opens 10 degrees ATC

Breather closes 55 degrees ABC

We recommend using maximum specifications in competition

engines. In most street engines if specs are within opening and

closing tolerance ranges, do not remove any additional material.

1957 to -‘77 Harley-Davidson

®

Sportster

®

model

Breather Timing

Examination of some street engines has shown that breather

timing varies from engine to engine. This is because positioning

of the flywheel assembly in the crankcases changes the location

of the pump drive worm gear on the pinion shaft and how it

engages the oil pump gear.

2

Figure A