S&S Cycle Super Stock Cylinder Heads for 1966–1984 Shovelhead Models User Manual

Page 6

6

To prevent inaccurate torque readings and possible damage to cylinder head caused by thread seizure, lubricate head bolt threads with

antiseize compound such as Permatex® Anti-Seize Lubricant before installation. S&S® has received reports of thread damage associated

with other lubricants such as engine oil on head bolt threads.

3. Install Rocker Housings

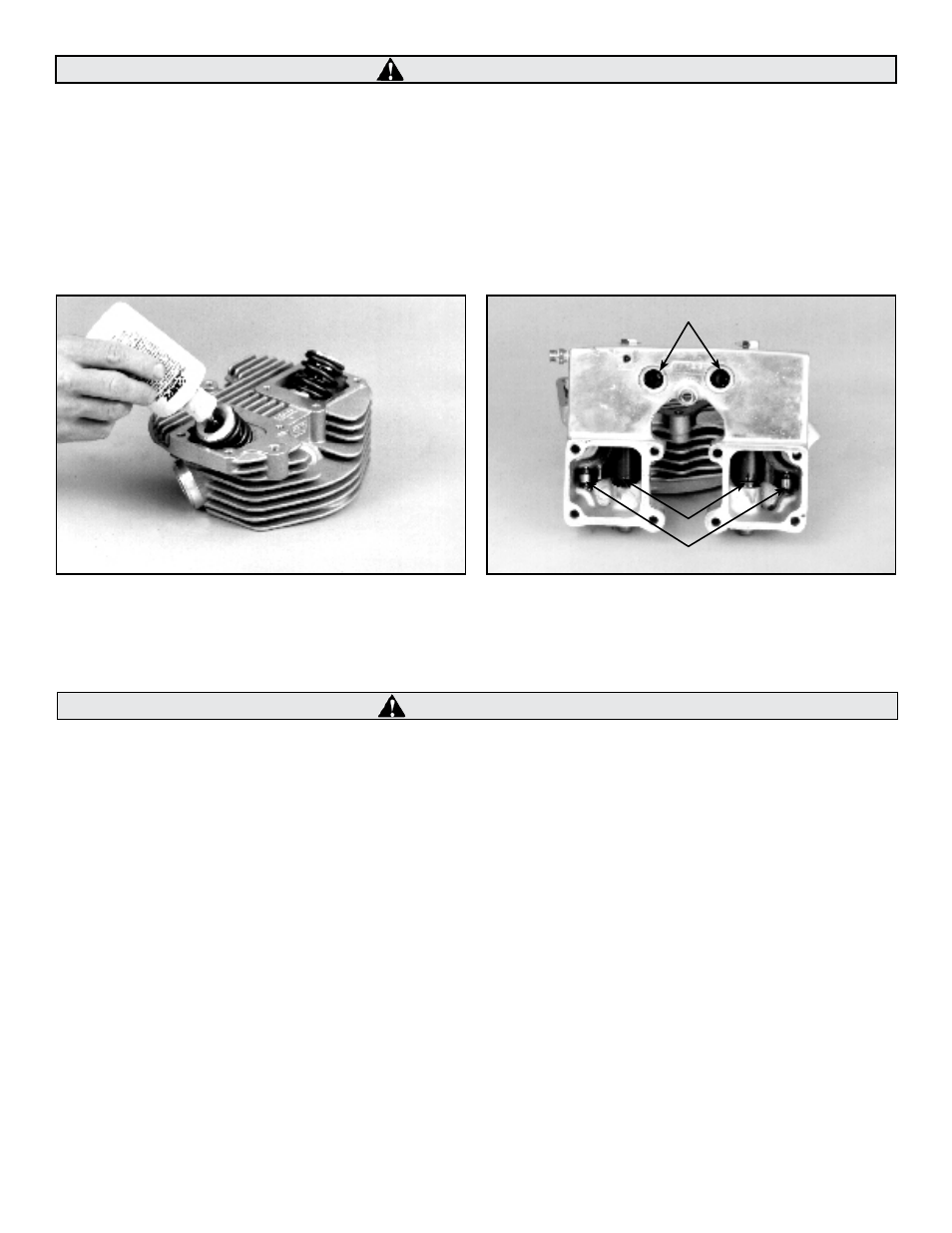

A. Apply assembly lube to valve tips, also to areas indicated. See Pictures 2 & 3, below.

B. Clean gasket surfaces of cylinder heads and rocker housings with lacquer thinner. Remove residue with clean, dry cloth.

C. Rocker housing gaskets currently supplied by S&S have factory applied silicone on one side. It may face either up or down. Apply thin film

of gasket sealant of choice to other side and allow to cure per manufacturer’s instructions.

NOTE: S&S has had good results with spray sealants such as Copper Coat® and Permatex® High-Tack. Regardless of type or brand, avoid excessive

sealant which can enter engine and obstruct critical oil passages.

Reduced oil circulation caused by oil passage obstruction can cause extensive engine damage not covered under warranty.

D. Place gaskets and rocker housings on cylinder heads.

NOTE: To maintain rocker arm in correct position, some engine builders place rocker housing upside down on flat surface and lower cylinder head onto

them. Assemblies can then be turned over for installation of hardware.

E. Determine whether 11⁄2" or 21⁄2" bolt is required in rear, camside position (See Figure 3, page 4) and discard other. Place required bolt with

remaining 5⁄16 -18 x 21⁄2" bolts and apply Loctite® 242 (blue) or equivalent to threads of each. Install and tighten in X-pattern to 15-18 ft-lbs.

See Picture 4, next page.

4. Install Cylinder Heads

A. Thoroughly clean cylinder and cylinder head gasket surfaces with lacquer thinner. Remove residue with clean, dry cloth. Apply thin coat of

anti-seize compound such as Permatex® Anti-Seize Lubricant to head bolt threads and area of bolt head that contacts cylinder.

B. Place head gasket on rear cylinder. Confirm that oil passage and head bolt openings line up correctly.

C. Place rear head on cylinder and loosely install two head bolts.

D. Apply PTFE tape or other thread sealant to oil line fittings in crankcase and rocker housings. Install new rubber sleeves on oil lines as needed,

and place overhead oil feed line between crankcase and rocker housing. Loose head bolts will allow head to be raised, eliminating need

to bend oil line. See Picture 5, next page. Loosely install other head bolts. Repeat procedure for front head and install remaining oil line

between rocker housings.

CAUTION

Picture 2

Picture 3

Apply assembly lube to areas indicated by arrows

CAUTION