Correct incorrect – S&S Cycle Super Stock Cylinder Heads for 1966–1984 Shovelhead Models User Manual

Page 3

2

3

INTRODUCTION

S&S® Super Stock® Cylinder Heads for shovelhead models are designed to fit all 1966-1984 shovelhead engines as well as earlier panhead and

knucklehead lower ends equipped with shovelhead cylinders and cylinder heads. The exterior dimensions of S&S cylinder heads for shovelhead

models are the same as stock. With a few minor exceptions, no modification should be necessary when replacing stock cylinder heads with S&S

heads.

NOTE: To reduce exhaust leakage, S&S exhaust ports feature tight fit around the exhaust pipe stub. This may require grinding stubs to reduce O.D. slightly.

Because of variations in castings, minor shimming of the top engine mount may also be required.

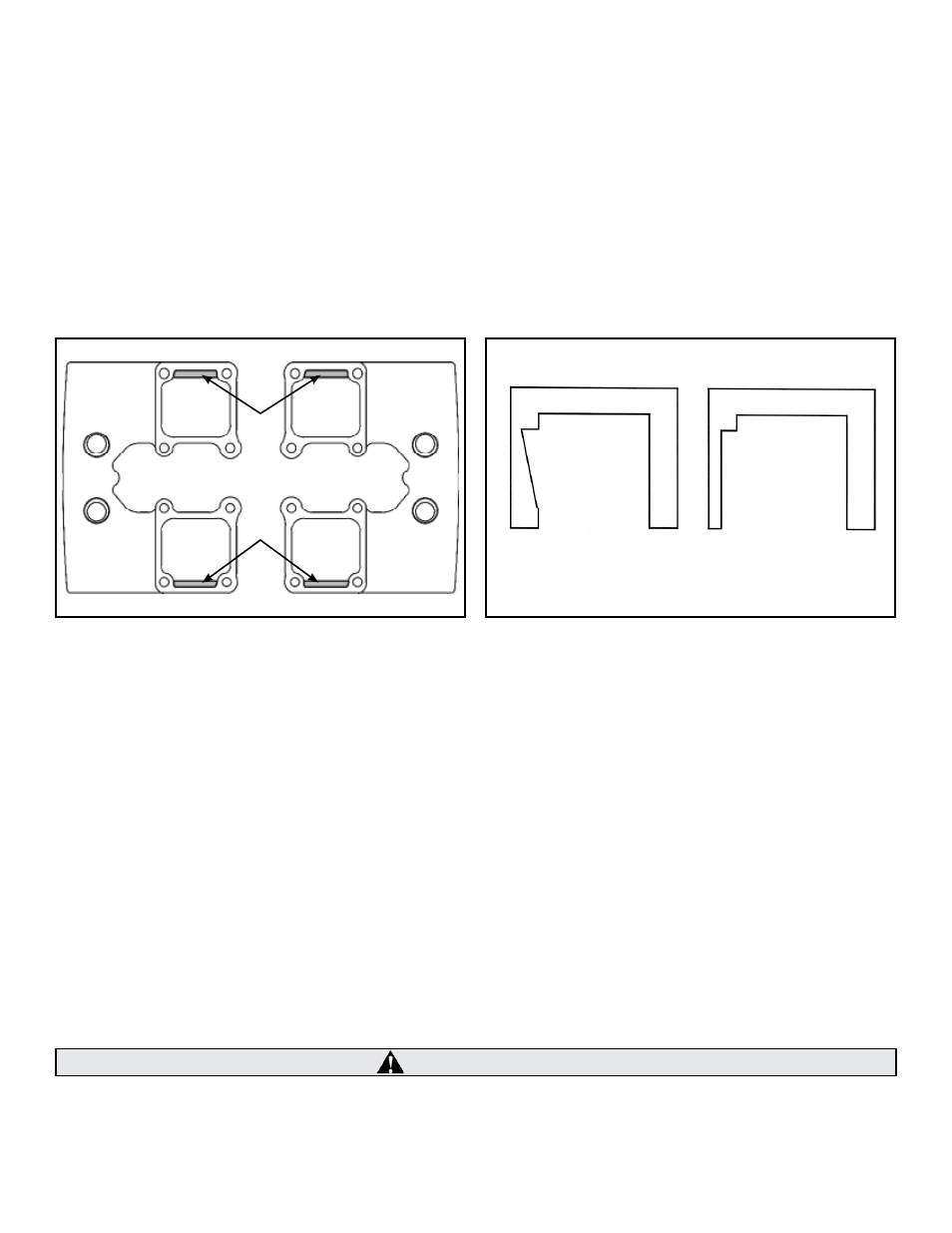

NOTE: Some shovelhead rocker housings have thicker walls which reduce clearance for top valve spring retainer. Remove material from inside of rocker

housing to obtain minimum clearance of .060” between housing and S&S top retainer. To maximize rocker housing gasket surface area, relief should be cut

at angle parallel to direction of valve travel rather than vertical. Remove least amount of material possible to obtain proper clearance. See Figures

1 & 2, below.

S&S cylinder head kits include all parts needed to install cylinder heads. Customer must supply related replacement items such as intake manifold

o-rings, pushrod cover seals and oil line sleeves. Except in fresh, low mileage engines, S&S recommends checking piston and cylinder wear at time

of cylinder head installation. Even if piston replacement is not required, honing cylinders and replacing piston rings is often beneficial.

Features of S&S Cylinder Heads for Shovelhead Models

•

Intake ports feature a directional vane and other changes to increase air flow. At approximately 135 CFM, flow in S&S heads is 10 CFM greater

than best stock heads tested by S&S. Because of variance in OEM castings, in many cases gain will be substantially higher.

•

Available with counterbore for 31⁄2" stock bore or 35⁄8" big bore cylinder.

•

Accept cam cams with valve travel of .590" without coil bind.

NOTE: It is the engine builder’s responsibility to confirm that adequate valve-to-valve and valve-to-piston clearances exist. S&S recommends a

.040" minimum valve-to-valve clearance, and .060" minimum valve-to-piston clearance. S&S cylinder heads for 1966-'84 shovelhead engines will

accomodate cam shafts with valve travel of up to .590" and TDC lifts of up to .210" on both valves

Under no circumstances should engine be forced if resistance is encountered while rotating flywheels to check clearances. Forcing

engine or failing to establish proper clearances can result in extensive engine damage not covered under warranty.

Figure 1

Shading indicates areas most likely to require modification

for spring retainer clearance. Relief should be cut at an angle,

not vertical.

Figure 2

CORRECT

INCORRECT

Valve compartment of rocker housing (cross section). If required,

relief should be cut at an angle (approximately the same angle as

the valve travel, not vertical). Remove least amount of material

possible to obtain proper clearance

CAUTION