Caution – S&S Cycle Cylinder Heads for Harley-Davidson Twin Cam 88 Engines User Manual

Page 4

Insufficient clearance between piston domes and cylinder

heads or piston domes and valves will cause damage to

pistons and cylinder head components.

B.

Repeat procedure to check rear piston to cylinder

gasket surface relationship.

C.

Check valve pocket fit.

NOTES:

G Valve pocket reliefs in stock Harley-Davidson

®

pistons are

smaller than those in S&S

®

pistons. Valve to piston clearance

should be checked if S&S heads are used with Harley-

Davidson

®

pistons and high lift cams. If S&S 79cc heads have

not been decked, valve to piston clearance is normally

adequate with cams such as the S&S 585G, with TDC lifts of

up to .186”/.179”. If cams with higher TDC lifts are used,

clearance must be checked.

G If S&S heads are used with S&S pistons no valve to piston

clearancing is normally required.

G If S&S heads are decked, valve to piston clearance should

be checked. If Harley-Davidson

®

pistons are used with

decked S&S heads, valve pockets must be modified in

nearly all cases.

1.

With cylinders and pistons installed, turn engine

over until piston in front cylinder is at top dead

center.

2.

Paint area around valve pockets on pistons with

machinist’s blue.

3.

Place valves in cylinder head leaving off springs

and retainers. Place head on cylinder and

secure with one bolt.

4.

Lower valves until they contact piston. Rotate

valve, marking painted area.

5.

Remove head and check points of contact. Valve

should fit in valve pocket machined in piston dome.

NOTES:

G S&S recommends a minimum of .060” clearance between

intake valve and piston valve pocket recess, and .080”

between exhaust valve and piston valve pocket recess at

piston TDC.

G When checking valve to piston clearance pushrods must be

adjusted so the hydraulic piston in tappet is bottomed in the

tappet bore or on the HL

2

T washer if used. This insures that

tappets can not bleed down so valve position will be

accurate for clearance check.

Insufficient clearance between piston and valves may cause

them to contact each other during operation resulting in

damage to piston and valve train components.

6.

If insufficient clearance exists, remove piston and

machine or grind valve pocket until head of valve

fits flush with proper clearance.

7.

Repeat procedure for other cylinder head.

D.

Check Valve to piston clearance at TDC.

1.

Spread layer of putty into valve pockets in both

pistons.

2.

Assemble cylinder heads and bolt on cylinders with

head gaskets in place. Install rocker covers and

pushrods. Adjust pushrods so the hydraulic piston

in tappet is bottomed in the tappet bore or on the

HL

2

T washer, if used. This insures that tappets can

not bleed down, so that valve position will be

accurate for clearance check.

3.

Turn engine over in normal direction of travel two

complete revolutions.

4.

Disassemble engine and check thickness of putty in

valve pockets.

5.

If insufficient clearance exists, machine or grind

piston until proper clearance is achieved.

6.

Disassemble top end and clean all parts for final

assembly.

E.

Remove cylinders and install piston rings and wristpin

clips per S&S Piston Instruction Sheet 51-1028.

F.

Coat piston skirts with engine oil and install cylinders.

NOTE - Stock Harley-Davidson

®

Twin Cam 88

®

cylinder heads

require two long and two short head bolts per cylinder. Stock

short head bolts can not be used with S&S cylinder heads for Twin

Cam 88

®

. The design of the S&S cylinder heads requires the use

of four long head bolts per cylinder. All head bolts are the same

length. Stock long head bolts can be used with stock length

motors, but the short head bolts must be replaced with long

head bolts Engines with longer than stock cylinders require four

special length, long head bolts per cylinder.

G.

Clean threads of head bolts and cylinder studs. Spin

each head bolt down on its respective stud to be sure

threads are clean and free of contamination.

H.

Install head gaskets dry. S&S 3

3

⁄

4

” bore heads gaskets

require O-rings around the cylinder head locating

dowels similar to stock head gaskets. S&S 3

7

⁄

8

” and 4”

bore head gaskets do not use O-rings around cylinder

head locating dowels.

I.

Place one or two drops of oil on threads and under the

head of each head bolt just prior to final assembly to

reduce friction and insure accurate torque readings.

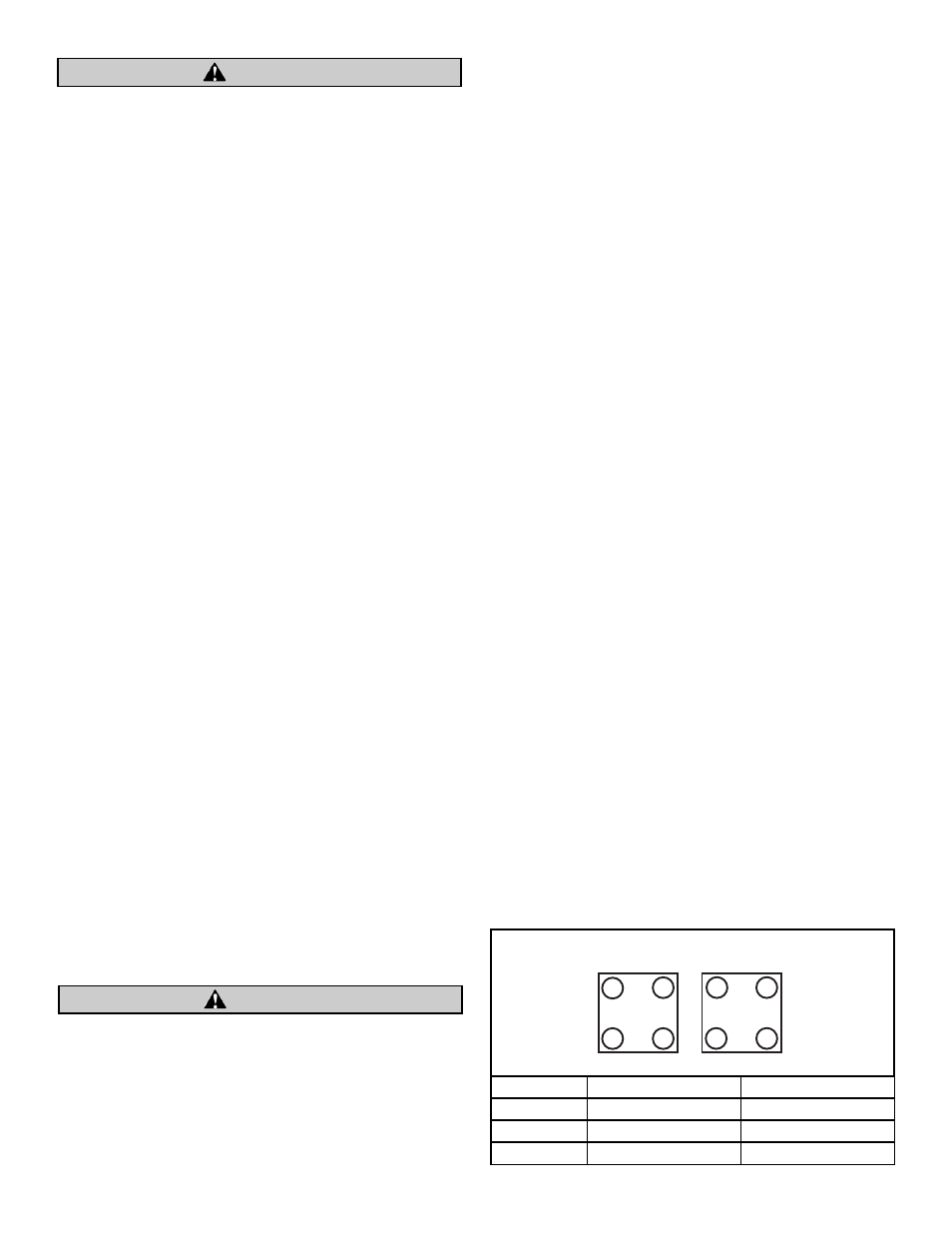

Bolt heads on cylinders. Tighten bolts in stages using

crossing pattern. See Figure 2.

4

CAUTION

1

2

4

3

Rear Head

2

1

3

4

Front Head

Top View

Driveside

Camside

Figure 2

S&S Head Bolts

Stock Head Bolts

Stage 1

8 Ft.-Lbs.

7-9 Ft.-Lbs.

Stage 2

18 Ft.-Lbs.

12-14 Ft.-Lbs.

Stage 3

Turn additional 90˚

Turn additional 90˚

CAUTION