Warning caution, Caution – S&S Cycle Cylinder Heads for Harley-Davidson Twin Cam 88 Engines User Manual

Page 3

Installation Steps

1.

Strip Motorcycle, Disassemble, and Inspect Parts

2.

Check Clearances and Install S&S

®

Cylinder Heads

3.

Finish Assembly of Top End, Install Carburetor and Replace

Gas Tanks

4.

Engine Break-In Procedure (For installations that include

new pistons.)

5.

Performance Notes.

Installation Instructions

Installation of an S&S Super Stock

®

cylinder head kit is easy and

can be performed by any Harley-Davidson

®

repair shop equipped

to do engine overhauls. No special tools other than those used

in normal overhaul repair work are required.

Read instructions thoroughly before starting work. When they

are completely understood proceed with installation.

1.

Strip Motorcycle, Disassemble, and Inspect Parts

Follow Harley-Davidson

®

factory procedures outlined in

Harley-Davidson

®

service manual for stripping motorcycle for

top end service.

NOTE - Disconnect battery and drain all gasoline from gas tanks

before doing any work.

Gasoline is extremely flammable and explosive under certain

conditions and toxic when breathed. Do not smoke. Perform

installation in a well ventilated area away from open flames

or sparks.

A.

Remove gas tanks and all other parts required to

perform top end service.

B.

Remove carburetor, rocker covers, pushrods, pushrod

tube assemblies, and cylinder heads.

NOTE - Be careful not to introduce any dirt or other foreign

material into crankcase during disassembly of engine.

Metal filings, dirt and any other foreign contamination in

engine may cause premature wear and/or irreversible

damage to bearings and other internal engine components.

C.

Thoroughly clean and inspect all parts that are to be

reused. Any parts that show signs of wear or damage

should be replaced.

D.

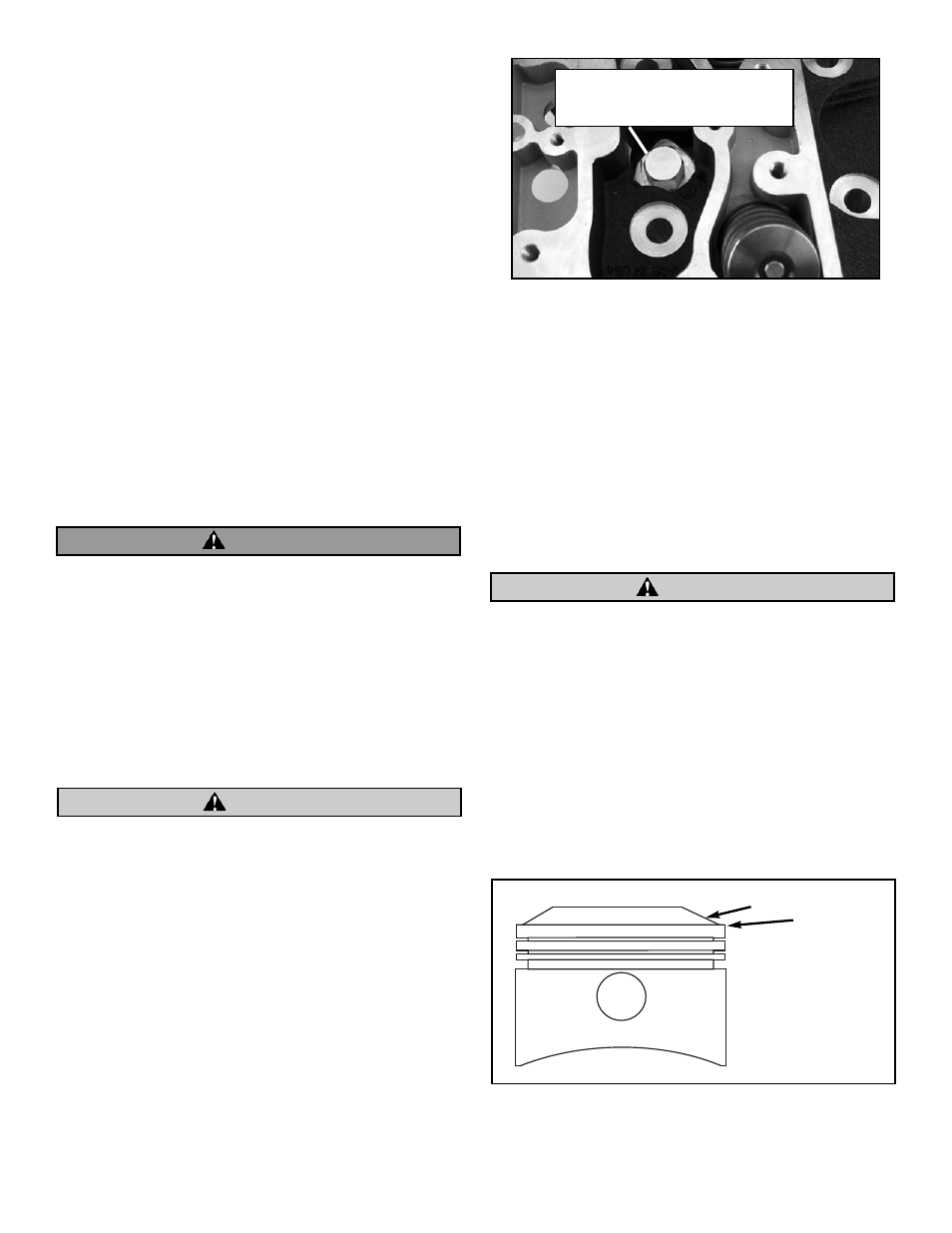

If S&S compression releases are to be used, they should

be installed in the new S&S cylinder heads at this time.

Compression releases can be installed with the engine in

the frame, but the procedure is much easier before the

heads are installed. Install compression releases per S&S

instruction sheets #51-1065 (manual) or #51-1109

(electric). If cylinder heads are machined for compression

releases, but compression releases are not going to be

used, #90-4916 threaded plug and #50-7094 washer

must be installed in the compression release hole of each

head and torqued to 30 ft.-lbs. See Picture 1.

2.

Check Clearances and Install S&S Cylinder Heads

NOTES -

G Since it is nearly impossible to anticipate every possible

engine combination, it is the engine builder’s responsibility

to check for proper running clearances. S&S considers

checking and establishing all running clearances as standard

engine building practice that must be performed during

engine assembly. Engine failure due to improper clearances

between moving parts is not covered under warranty.

G These instructions are for cylinder head removal and

replacement only. If replacing pistons and/or cylinders, refer

to the OEM or S&S Instructions for those components.

Contact between moving engine components may cause

damage or destruction of the parts involved and produce

abrasive particles which may cause damage or premature

wear to other engine components.

A.

While applying pressure to hold cylinders in position,

rotate flywheels so front piston is positioned at top

dead center. Note where piston deck (See Figure 1) is

positioned in relationship to head gasket surface. Piston

deck (flat located just above top compression ring

groove), not dome, must be flush with or slightly below

gasket surface. If piston deck is higher than cylinder at

top dead center, something is wrong and S&S should be

notified.

NOTE - Stock and S&S engines are designed so that at top dead

center, piston deck should be flush with or slightly below head

gasket surface of cylinder. Piston to head clearance is provided by

thickness of head gasket (.045” for S&S engines).

3

WARNING

CAUTION

Picture 1

CAUTION

#90-4916 plug and #50-7094 washer

installed when compression releases are

not used.

Figure 1

Dome (Pop-up)

Deck