Caution warning caution – S&S Cycle Stock Replacement 3 7/16 and 3 1/2 Bore Shovelhead Cylinders User Manual

Page 3

D. Perform Steps A through C on other cylinder.

E.

Bolt front and rear cylinders on drive side

crankcase half.

F.

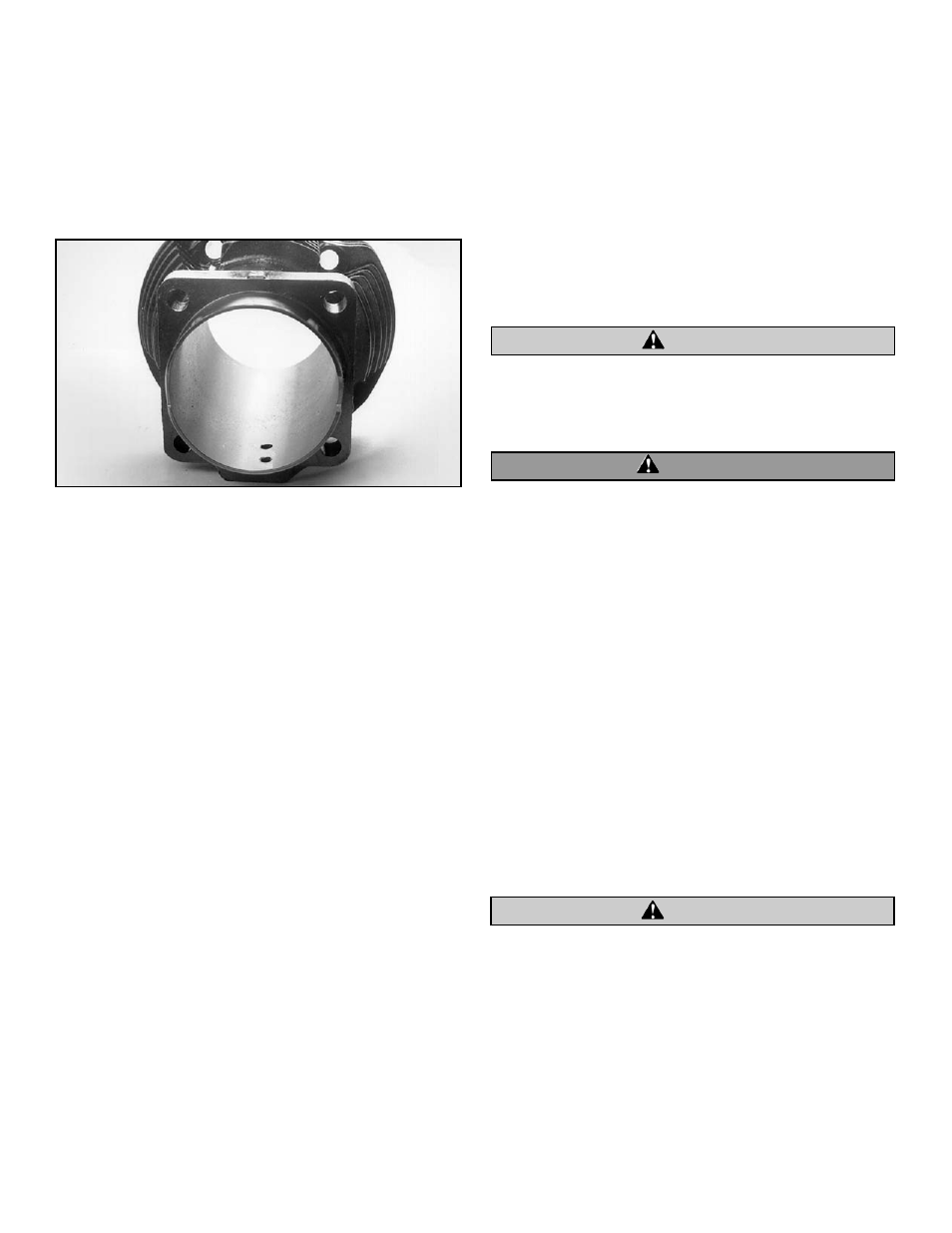

Using lower oil return hole in cylinder spigots as a

guide, drill

1

⁄

4

" diameter connecting holes in

crankcase to intercept holes drilled

5

⁄

8

" deep in

Step C. See Picture 1 & Figure 1.

NOTES:

●

If base plates are to be used, be sure they are in place.

●

Lower oil return hole in current production S&S

®

cylinders is

1

⁄

2

" on center below base gasket surface of

cylinder. This dimension allows the use of up to 5"

stroke using a

1

⁄

8

" thick base plate. Some early

production cylinders have lower oil hole located

about

5

⁄

16

" on center below gasket surface. These early

production cylinders can be used with strokes up to 4

3

⁄

4

" where base plates are not used.

G. Clean dirt, filings, etc. out of passageways.

H. Press a piece of

3

⁄

4

" long x

3

⁄

8

" O.D. steel tubing

(93-1032) provided in kit into oil return hole in

base gasket surface until tubing is flush with

surface. Ream hole slightly with drill to remove

any burrs that may exist.

NOTE: A very tight press fit with 100% seal is not critical as

tube will sufficiently divert oil flow to new hole. Loctite

®

may be applied to tube if fit seems too loose.

3.

Hone cylinders to fit pistons. If using S&S pistons refer

to S&S Piston Installation Instruction Sheet #2500 for

piston to cylinder clearance specifications. If using

other pistons, refer to manufacturer’s instructions for

clearance specifications.

NOTE: S&S recommends the use of 220 - 280 grit stones for

final honing of cylinder. A finer finish does not retain oil on

the cylinder wall as well. This may result in inadequate

piston skirt lubrication and piston scuffing.

4.

Thoroughly clean all parts before final assembly.

NOTE: Cleaning parts prior to and during assembly and

keeping parts clean after final assembly are imperative to

minimize contaminants that may circulate in oil and

shorten engine life. Many parts can be cleaned with soap

and water first. Then, reclean all internal parts and gasket

mating surfaces using high quality solvent that does not

leave any harmful residues. Be sure to read and follow

manufacturer’s instruction label before use. Use drills and

compressed air to clean all oil passageways of dirt, filings,

etc. whenever possible. During actual final assembly,

recoat all internal parts with high quality engine oil or

assembly lube such as S&S 51-9000.

Manufacturing chips, dirt and other contaminants

circulating in engine oil may possibly damage engine

components resulting in shorter engine life and

possible engine failure.

●

Some solvents, degreasers and other chemicals are

harmful to skin, eyes and other body parts. Many

items are flammable and present a fire hazard. Read

manufacturer’s instruction label for proper use. Use in

well ventilated area and wear protective clothing

when using them to avoid personal injury.

●

Compressed air and particles dislodged by

compressed air are harmful to eyes and body. Wear

protective goggles when using compressed air and

always direct air stream away from body parts such as

hands and eyes. Never direct compressed air toward

other people.

5.

Assemble engine according to stock Harley-Davidson

®

factory procedures. If installing a high performance kit

such as an S&S stroker kit follow special procedures

outlined in kit instructions.

NOTE: If using S&S base nuts, use a heavy duty

1

⁄

2

" open end

wrench like the Mac Tools CL-166KS. Other thinner

wrenches will spread and round corners of nut before

providing enough torque to adequately tighten base nut.

Insufficiently tightened cylinder base nuts may cause

base gasket leaks. If base nuts become loose enough

that cylinder is not held tightly to the crankcase,

repeated impact between crankcase and cylinder base

may cause base flange of cylinder to crack.

3

Picture 1

CAUTION

WARNING

CAUTION