Caution – S&S Cycle Stock Replacement 3 7/16 and 3 1/2 Bore Shovelhead Cylinders User Manual

Page 2

INTRODUCTION

S&S

®

stock bore shovelhead cylinders are designed for

stock replacement and high performance applications in

74" and 80" shovelhead engines. Superior material and

design provide increased strength and improved wear

resistance.

NOTES:

●

Cylinders for 74" engines have a bore size of 3.437",

and 80" cylinders have a bore size of 3.498". S&S

cylinders are final honed slightly undersize to allow

maximum flexibility in piston fitting.

●

Due to increased section thickness S&S cylinders

require the use of special S&S head bolts. Early

production S&S cylinders also require the use of special

S&S cylinder base nuts. Stock cylinder base nuts may

be used with current production S&S cylinders.

●

The S&S rear cylinder does not have the larger base

flange found on stock cylinders. For this reason S&S

supplies a special rear gasket to fit the smaller base

flange. Stock gaskets may be trimmed to fit if desired.

●

S&S cylinders are machined with two oil return holes.

One hole is in the stock location and the other is

lowered for stroker applications. These cylinders may

be bolted on as is for stock replacement applications,

but minor crankcase and cylinder oil return hole

modifications are necessary for most stroker engines.

See Step 2.

●

S&S cylinders are clearanced for S&S Supreme

connecting rods in engines of up to 4

3

⁄

4

" stroke.

However since it is nearly impossible to anticipate

every possible engine combination, it is the engine

builder’s responsibility to check for proper running

clearances. S&S considers checking and establishing

all running clearances as standard engine building

practice that must be performed during engine

assembly. Engine failure due to improper clearances

between moving parts is not covered under warranty.

Contact between moving engine components may

cause damage or destruction of the parts involved and

produce abrasive particles which may cause damage or

premature wear to other engine components.

To avoid parts damage and obtain accurate torque

readings, clean head bolt threads thoroughly before

installation. For knucklehead, panhead, or shovelhead,

head bolt threads and area of bolt head that contacts

washer (if applicable) or cylinder must then be

lubricated with Permatex

®

Anti-Seize Lubricant or

similar anti-seize compound. S&S has received reports

of thread damage in these engines associated with use

of engine oil to lubricate head bolts.

INSTALLATION

1.

Inspect cylinders to insure that they are correct for the

intended application.

2.

For engines of 4

1

⁄

2

" or longer stroke, the oil return holes

in the stock location must be plugged, and the

crankcase must be modified to use the lowered oil

return holes. This modification is necessary due to

increased piston travel in longer stroke engines. Oil

control ring position will be below stock cylinder oil

return hole at the bottom of the stroke. If modification

is not done, oil will be carried to the combustion

chamber by piston rings causing engine to smoke.

NOTE: Engines with stroke shorter than 4

1

⁄

2

" stroke do not

require this step.

A. If using stock cylinder base gaskets, place base

gasket on cylinder base gasket surface, and punch

1

⁄

4

" hole in gasket directly in center of oil return

hole in base gasket surface of cylinder. S&S gaskets

are pre-punched.

B. Place gasket on driveside crankcase half in its

respective position. Mark crankcase gasket surface

through

1

⁄

4

" diameter hole in gasket.

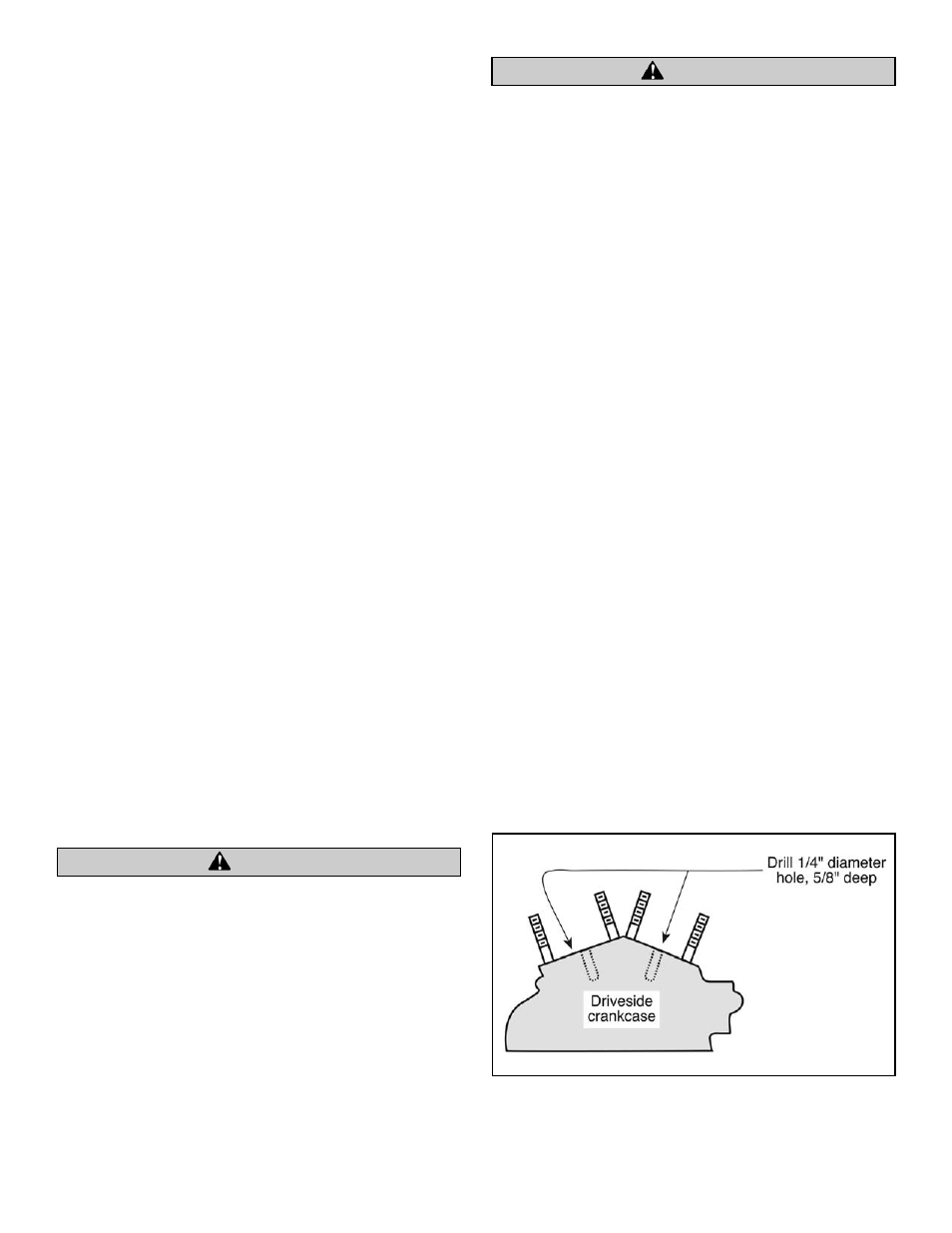

C. Drill

1

⁄

4

" diameter hole perpendicular into crankcase

gasket surface

5

⁄

8

" deep. See Figure 1.

2

CAUTION

CAUTION

Figure 1