S&S Cycle Non-Copper Head Gaskets for Harley-Davidson Evolution & Twin Cam 88 Engines User Manual

Page 2

NOTE: Light coating of oil on head bolt threads

minimizes friction so torque values will not be

distorted. It cannot be emphasized enough

how important it is to do these steps carefully.

Maintaining a good head gasket seal depends

on it.

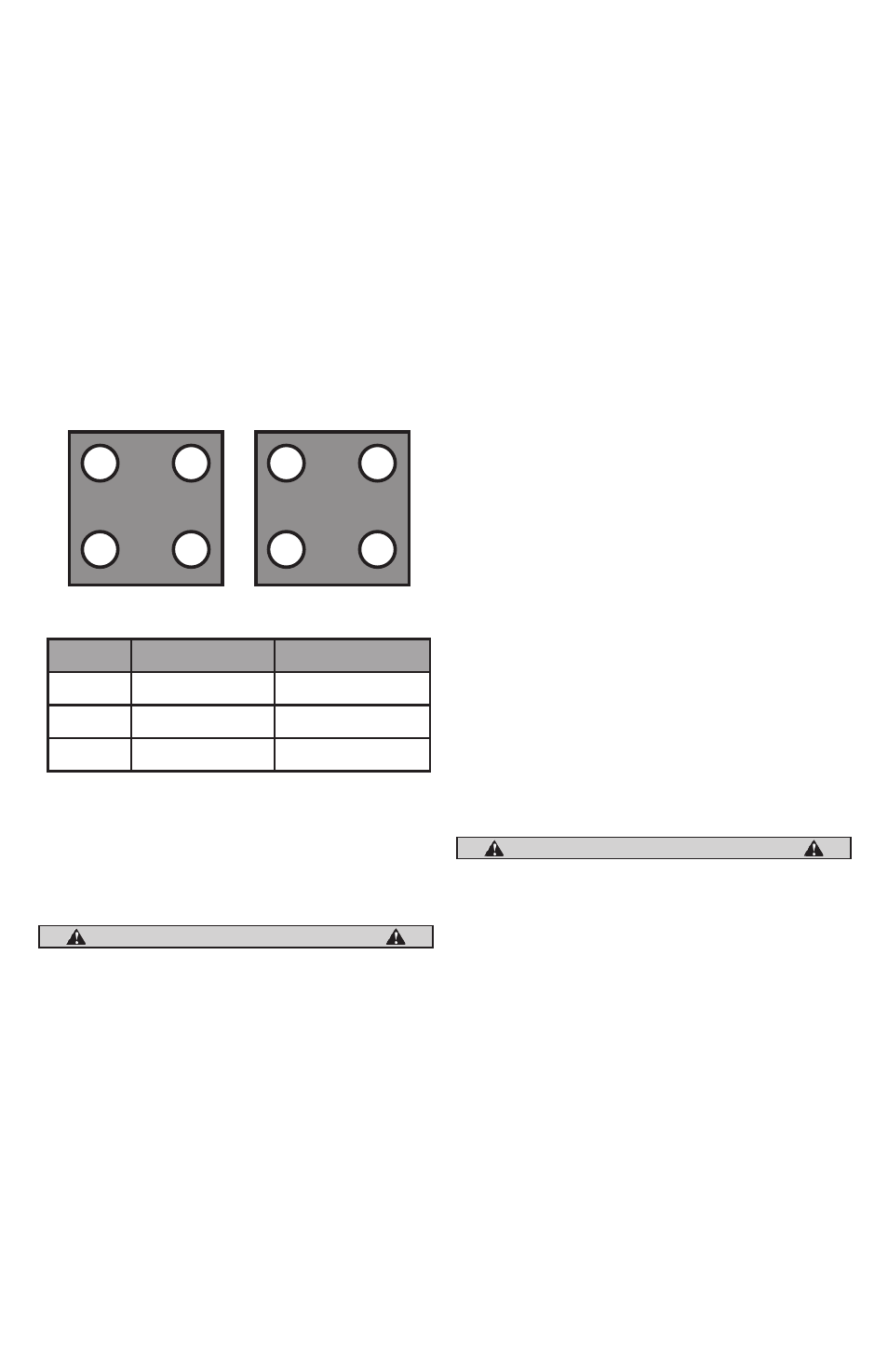

G. Bolt heads on cylinders using stock washers

and head bolts or S&S® washers and head

bolts when provided. Tighten head bolts in

stages using crossing pattern shown below.

Use torque specifications appropriate for

crankcase type. Do not exceed specified

torque values.

NOTE: Stock head bolt torque specifications

must be used with stock crankcases. Stronger

material used in S&S crankcases allow the use of

higher torque values.

CAUTION

Improper torquing sequence and head

bolt torque values may cause head gasket

failure. Exceeding specified torque values

may cause cylinder studs to pull out

of crankcases, resulting in damage to

crankcases and loss of head gasket seal.

H. Finish assembling top end per OEM

instructions. Install and adjust pushrods

per factory specifications, or manufacturers

pushrod instructions.

Initial Start Up

A. Run engine approximately one minute at

1250-1750 rpm. DO NOT crack throttle or

subject engine to any loads as head gaskets

are susceptible to failure at this time. During

this time check to see that oil pressure is

normal, that oil is returning to the oil tank,

and that no leaks exist.

B. Shut off engine and thoroughly check for

any leaks or other problems. Let engine cool

to the touch

C. After engine has cooled, start up again and

allow the motor to build some heat. Engine

should be run no longer than three to four

minutes. When the cylinders become warm/

hot to the touch (approximately 150°) shut

the motor down and let it cool to room

temp. Follow the same cautions as for the

initial start-up, and continue to watch for

problems.

D. Repeat this procedure 3 or 4 times. With a

new engine, each successive time should

take slightly longer to warm up and you can

increase the temp slightly each time (+10°).

You can be more liberal each time with the

rpm, gently vary rpm continuously from

idle up to 2500 rpm in the final cycle. Do

not allow engine temperature to become

excessive. After the motor has cooled to

room temperature for the final time the

motorcycle can be ridden normally.

E. If the engine is new or newly rebuilt, adhere

to the break-in procedure specified by the

manufacturer of the components installed.

CAUTION

•

Improper first time engine start-up and

break-in procedure may cause head

gasket failure.

•

Do not allow engine temperature to

become excessive as permanent engine

damage may result.

Top View Driveside

Head Bolt Torquing Sequence

1

2

3

4

2

1

4

3

S&S® Case

Stock Case

Stage 1 8 ft-lbs

7–9 ft-lbs

Stage 2 18 ft-lbs

12–14 ft-lbs

Stage 3 Turn 90˚ more Turn 90˚ more