S&S Cycle Torque Plate Kit for 4 3/8 Bore Cylinders User Manual

Page 3

NOTE: Install cylinder head dowels to locate top plate. The

torque plate must be centered on cylinder bore so boring

cutter or honing stones will not strike the torque plate

during operation.

7. Torque bolts to 40 ft-lbs. in same pattern used to

install heads during engine assembly.

See Figure 1. Tighten bolts in following stages:

Stage I

10 ft-lbs.

Stage II

20 ft-lbs.

Stage III

40 ft-lbs.

B. HONING 4

3

⁄

8

" BORE CYLINDERS USING TORQUE PLATES

Honing on a horizontal hone

1. When using a horizontal style hone, care must be

taken to avoid honing bore out of round. The

cylinder must be supported so that the stones cut

evenly around the inside of the cylinder. Unless

properly supported, the combined weight of the

assembled cylinder and torque plate can cause the

stones to cut unevenly resulting in irreparable

damage to cylinder.

2. A stabilizer arm (53-0014) is supplied with the

plate set. The arm rests against the bar of a

horizontal hone, and keeps the cylinder from

rotating during the honing operation. The two

pins at one end of the bar are inserted into

matching holes in the bottom plate. For stabilizer

arm detail, See Picture 1.

3. The cylinder can be honed from either end. After

making a few strokes, stop and measure progress

with a dial bore gage. After each measurement, it

is a good practice to alternate honing from one

end then the other. This will help achieve a

straight, round bore.

4. Do not reuse the gaskets from the boring/honing

operation when assembling the engine.

Honing in a vise using a portable hand held hone.

1. A vice tab (53-0034) is supplied with the plate set.

The tab allows the lower torque plate to be held

in a vice. The tab has two pins that are inserted

into matching holes on the lower torque plate,

and it is held in place with a supplied

5

⁄

16

" x 1" bolt.

For vice tab detail,

See Picture 1.

2. The cylinder can be honed from either end. After

making a few strokes, stop and measure progress

with a dial bore gage. After each measurement, it

is a good practice to alternate honing from one

end then the other. This will help achieve a

straight, round bore.

3. Do not re-use the gaskets from the boring/honing

operation when assembling the engine.

3

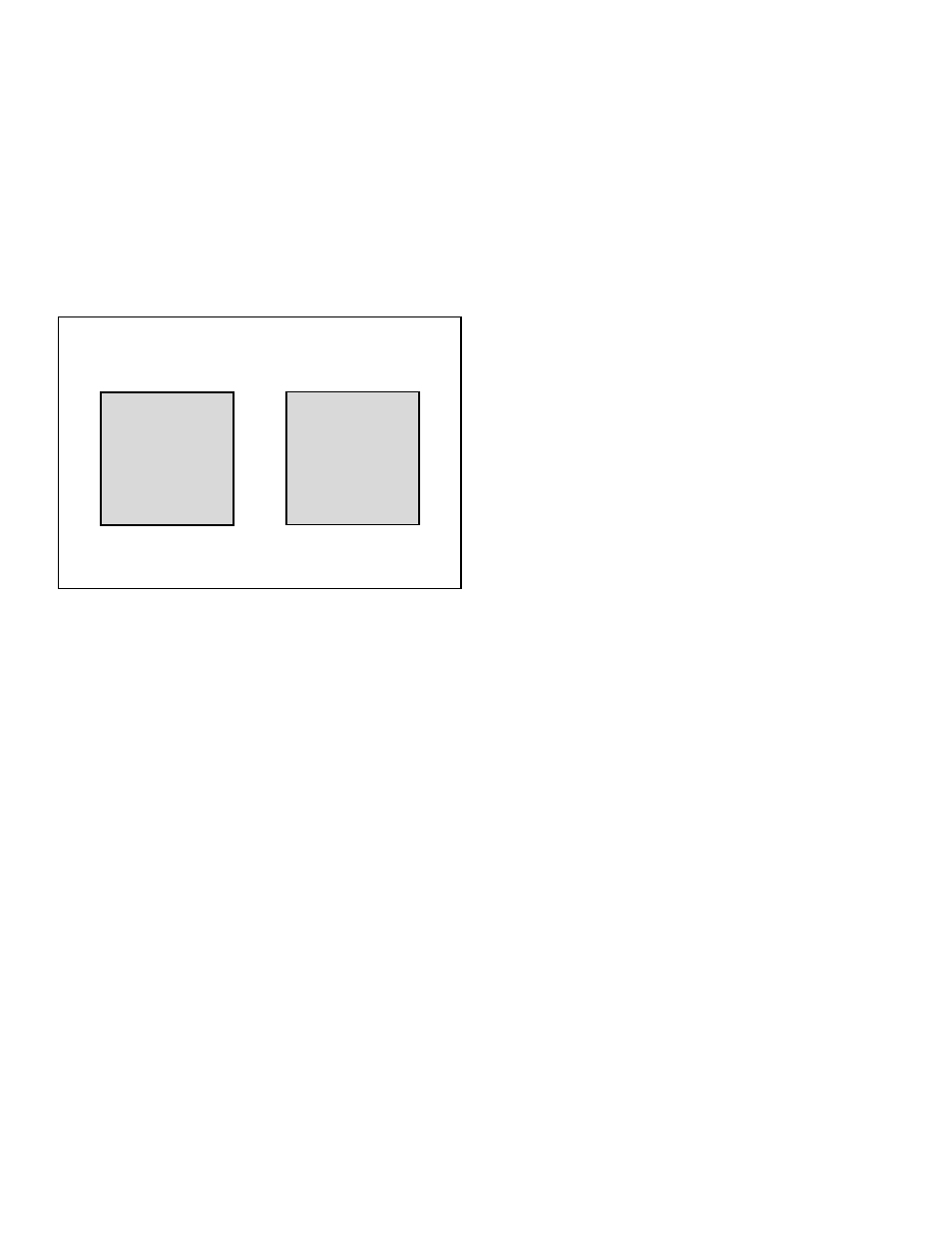

Figure 1

1

2

4

3

Rear Cylinder

Camside

Driveside

2

1

3

4

Front Cylinder

S&S

®

4

1

⁄

8

" Bore Torque Sequence