Caution warning – S&S Cycle Torque Plate Kit for 4 3/8 Bore Cylinders User Manual

Page 2

INTRODUCTION

S&S

®

cylinder torque plates simulate the stress cylinders

experience when installed on an engine during honing

operations. A cylinder that has been honed between

torque plates holds to its installed dimensions better

than a cylinder honed without torque plates.

Torque plates for 4

3

⁄

8

" bore cylinders can be used with

either horizontal Sunnen

®

type hones, or portable hand

held hones.

If a vertical Sunnen

®

type hone is used, a holding

fixture will have to be fabricated. A boring

plate/honing fixture is not available from S&S for use

with 4

3

⁄

8

" bore torque plates.

KIT CONTENTS

Torque Plate Kit 53-0055 is for 4

3

⁄

8

" bore cylinders. It

includes the following parts:

Part 53-0056 (1) Head-end torque plate

Part 53-0057 (1) Base-end torque plate

Part 53-0014 (1) Torque plate stabilizer arm

Part 50-0192 (4)

7

⁄

16

" - 20 x 7" Grade 8 SHC screws

NOTES:

●

Always observe professional practices and wear

safety glasses and protective clothing when

operating machinery.

●

S&S torque plates are hardened and must not

come into contact with cutter or honing stones

during operation.

NOTE: Torque values for torque plate hardware may vary

significantly from values used to assemble engine.

Improper operation of machinery or fixtures can

damage motorcycle parts, tools and/or machinery

components.

Improper operation of machinery and associated

equipment can cause personal injury to operator and

others nearby. Contact a professional mechanic if

unsure of correct procedure.

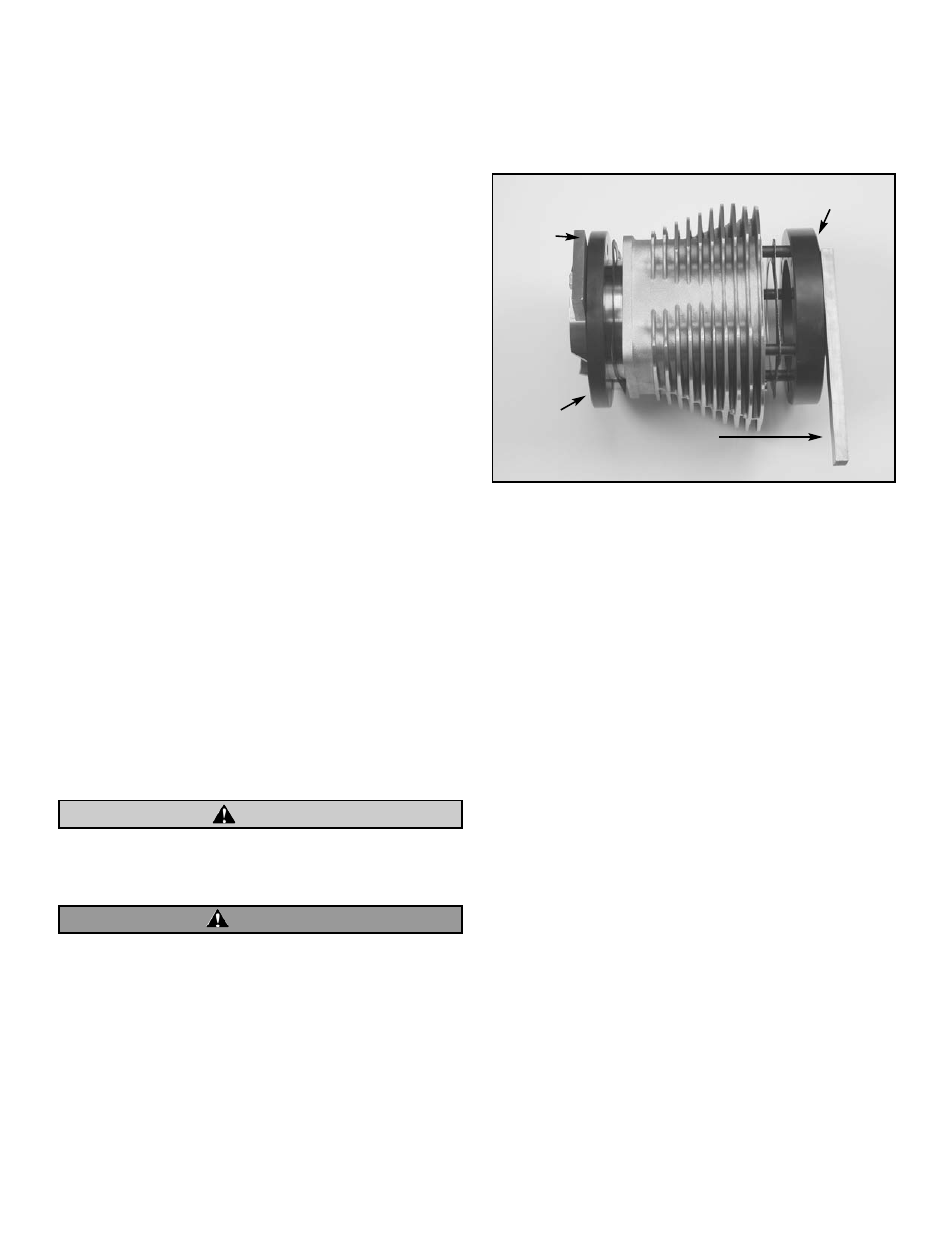

A. TORQUE PLATE INSTALLATION

The first step of any boring or honing operation is

installing and torquing the plates to the cylinder. See

Picture 1 and the following instruction.

NOTE: The front and rear stud pattern of S&S 4

3

⁄

8

" bore

engines is the mirror image of a non-symmetrical pattern.

The top and bottom torque plates can be installed with

either side facing towards the cylinder, but hole alignment

depends on whether the plate is used on a front cylinder,

or a rear cylinder. If rotating the plate around the pattern

doesn't align the holes, flip the plate over and try again.

The top plate is always used at the top, the bottom plate

is always used at the bottom.

1. Place base gasket over end of cylinder spigot.

2. Place bottom torque plate over end of

cylinder spigot.

3. Apply light coat of 20W50 motor oil to threads and

underside of heads of the four provided

7

⁄

16

"-20 x 7"

socket head bolts.

4. Insert the four

7

⁄

16

" bolts thru the holes in the top

plate. The heads of the bolts go into the

countersinks in the top plate.

5. Place a head gasket over the four

7

⁄

16

" bolts.

6. Insert the

7

⁄

16

" bolts with the gasket and top plate

thru the cylinder. The head gasket will be between

the top plate and the cylinder.

2

CAUTION

WARNING

Picture 1

Torque plates must be used with gaskets.

Vise Tab

Used for

securing

assembly

in a vise

for hand

honing.

Bottom Plate

Top Plate

Stabilizer Arm

Used to keep assembly from

turning when horizontal honing.