S&S Cycle Forged Pistons For Stock Bore And 35/8 Bore Harley-Davidson 1936-99 Big Twin And 1957- Present Sportster Models User Manual

Page 3

3. For ring kits in which section #2 above does not apply, compression

rings may be of plain cast iron type, chrome faced cast iron type,

moly faced cast type or chrome type.

a. The most common combinations are:

i. Two chrome faced cast rings

ii. One chrome faced cast ring & one plain cast ring.

iii. One moly faced cast ring & one plain cast ring.

b. Install as follows:

i. Chrome faced or moly faced ring always goes in top groove

ii. Plain cast ring usually goes in second groove. Plain cast type is

usually a reverse torsion ring distinguished by an inside diameter

bevel on one side of ring and a "dot" or oversize mark on other

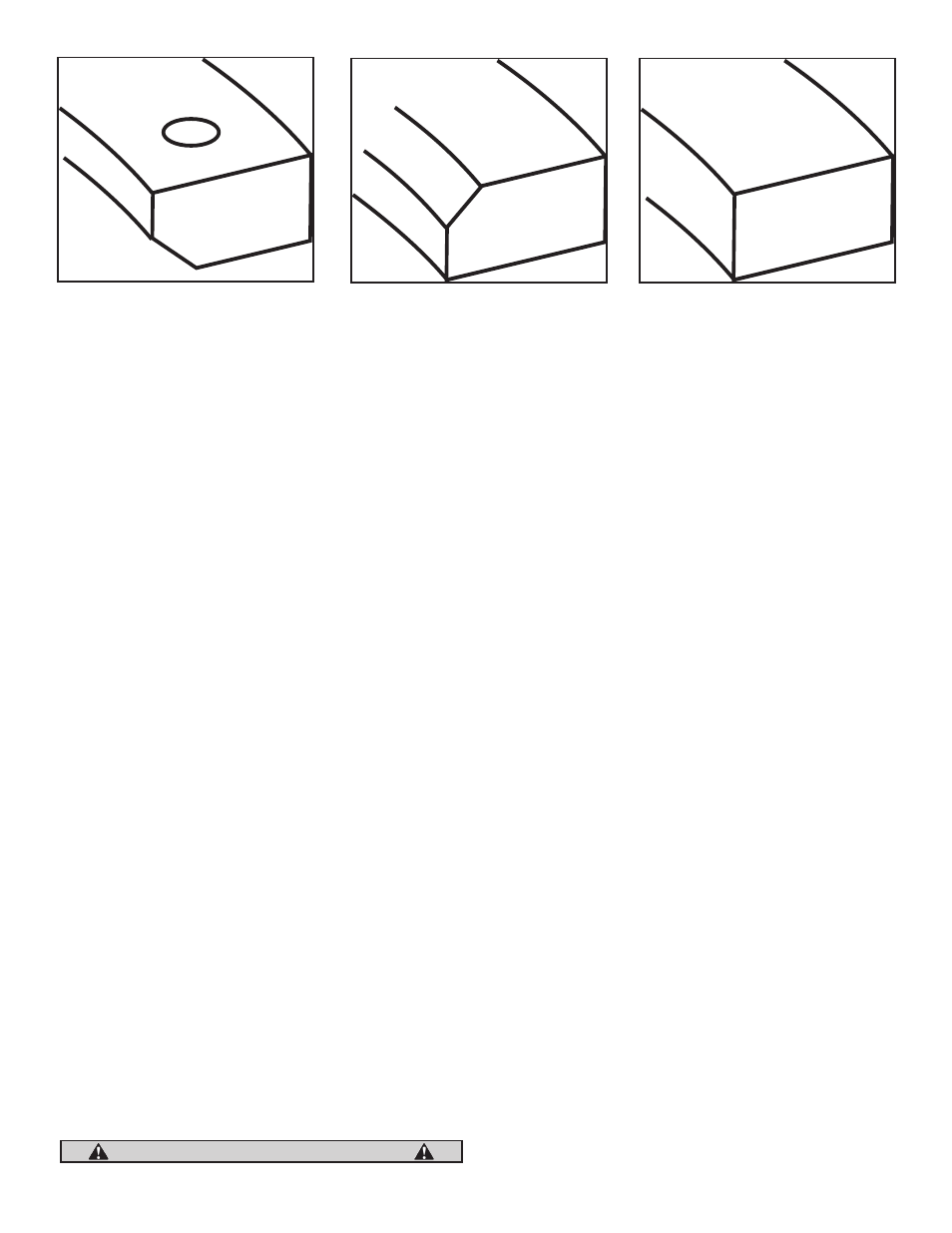

side. See Figure 1 above. If two cast iron compression rings are

supplied in a set, check to see if one is reverse torsion style ring

with dot and bevel. Reverse torsion style ring always goes in

second groove with dot up if present.

c. The following rules apply to compression ring identification and

placement. Rules are listed in order of priority. In other words,

if both Rule #2 and Rule #4 apply, for example, Rule #2 will be

followed and Rule #4 ignored.

i. Chrome or moly ring goes in top groove.

ii. Cast iron regular or reverse torsion ring goes in second groove.

iii. Any identifying "pip" marks, dots or oversize marks go to top of

piston.

iv. Ring with one dot goes in top groove, ring with two dots goes in

second groove.

v. If both rings are identical and have one dot or two dots, either

ring can go in either groove.

vi. If ring has dot and inside diameter bevel, dot goes to top of

piston. See Figure 1above.

vii. If ring has no dot but does have inside diameter bevel, bevel goes

to top of piston. See Figure 2 above.

viii. If ring has no dots and no bevel, it can go either way. See Figure

3 above.

4. Ring Gap Measurements

a. Compression ring end gap on big twins with 37⁄16", 31⁄2" and 35⁄8"

bore is .014" to .022".

b. End gap on all other compression rings is .016" to .024".

c. Oil ring rail end gap on big twins with 37⁄16", 31⁄2" and 35⁄8" bore is

.015" to .035".

NOTE: In certain instances, the next oversize ring set may be supplied

with pistons, for example + .060" oversize rings with +.050" pistons. In this

case end gaps must be measured and rings filed as necessary. Ends must

then be carefully deburred.

CAUTION

Failure to deburr rings may result in engine damage.

5. Install ring support rail in front piston so that the end gap is toward

the rear of the cylinder (90° from wristpin). Install ring support rail

on rear piston so that the end gap is toward front of the cylinder (90°

from wristpin).

6. Ring Gap Placement

a. Oil ring

i. Expander gap must be in center of thrust face (rear of piston), or

90° from wristpin.

ii. Bottom rail gap should be approximately 1.5" or 45° to right of

expander gap.

iii. Top rail gap should be approximately 1.5" or 45° to left of

expander gap.

NOTE: Confirm that ends of expander do not overlap during installa-

tion. Properly installed expander will appear larger than piston but will

compress when cylinder installed.

b. Top compression ring gap should be 135° or approximately 41⁄2" to

left of oil expander gap.

c. Second compression ring gap should be 135° or approximately

41⁄2" to right of oil expander gap.

*

NOTE:

Fit wristpins at .0007" to .0014.”

ENGINE BREAK-IN PROCEDURE

NOTES:

S&S® engines are designed for high performance and as such are not

as tolerant of inadequate break-in. Correct break-in will assure longer

engine life and will prevent unnecessary engine damage. Engine damage

caused by improper break-in is not covered under the S&S warranty.

If new pistons have not been installed, only steps A, B, and C are required.

If new pistons have been installed, all break in steps are required.

1. Initial start up. Run engine approximately one minute at 1250-1750

rpm. DO NOT crack throttle or subject to any loads during this

period as head gaskets are susceptible to failure at this time. During

this time check to see that oil pressure is normal, that oil is returning

to the oil tank, and that no leaks exist.

2. Shut off engine and thoroughly check for any leaks or other

problems. Let engine cool to the touch

3. After engine has cooled, start up again and allow the motor to

build some heat. Engine should be run no longer than three to

four minutes. When the cylinders become warm/hot to the touch

(approximately 150°) shut the motor down and let it cool to room

temp. Follow the same cautions as for the initial start-up, and

continue to watch for problems.

Figure 1

Figure 2

Figure 3