S&S Cycle Piston and Cylinder Kits for all 1986-up Harley-Davidson Sportster Models User Manual

Page 4

a. Initial start up. Run engine approximately one minute at

1250-1750 rpm. DO NOT crack throttle or subject to any loads

during this period as head gaskets are susceptible to failure

at this time. During this time check to see that oil pressure is

normal, that oil is returning to the oil tank, and that no leaks

exist.

b. Shut off engine and thoroughly check for any leaks or other

problems. Let engine cool to the touch

c. After engine has cooled, start up again and allow the motor

to build some heat. Engine should be run no longer than

three to four minutes. When the cylinders become warm/hot

to the touch (approximately 150°) shut the motor down and

let it cool to room temp. Follow the same cautions as for the

initial start-up, and continue to watch for problems.

d. Repeat this procedure 3 or 4 times. Each successive time it

should take slightly longer to warm up and you can increase

the temp slightly each time (+10°). You can be more liberal

each time with the rpm, gently vary rpm continuously from

idle up to 2500 rpm in the final cycle. Don’t be too concerned

with final carb settings at this time because idle speed and

mixture cannot be correctly set until the motor reaches

full operating temperature. The motor should not reach

that temperature during these cycles. Do not allow engine

temperature to become excessive. After the motor has

cooled to room temperature for the final time you are ready

to start the 1000-mile engine break-in process.

e. The first 50 miles are most critical for new rings and piston

break-in. Engine damage is most likely to occur during this

period. Keep heat down by not exceeding 2500 rpm. Avoid

lugging the engine, riding in hot weather, or in stop and go

traffic. Vary the engine speed, but do not lug the engine. We

recommend changing the oil at 50 miles.

CAUTION

Lugging or running engine prematurely at sustained high rpm

may result in damage to pistons and other engine components.

S&S® voids its guarantee if engine is not broken in properly.

f. The next 500 miles should be spent running engine no faster

than 3500 rpm or 60 mph. Avoid continuous steady speeds,

and do not lug the engine. Vary engine rpm. We recommend

changing the oil again at 500 miles.

g. For the balance of the first 1000 miles the motor can be

run in a normal but conservative manner. You can be more

liberal with the rpm range and motorcycle can be operated

at normal highway speeds. Avoid overheating or putting

any hard strain on the engine: no drag racing, dyno runs,

excessive speed, trailer towing or sidecar operation.

h. After 1000 miles, verify carburetor jetting and adjustment.

Change the engine oil. Motorcycle can now be operated

normally.

i. Have Fun!

Additional Information:

The following information is provided in case pistons must be

replaced as in the event of an engine overhaul, or if the engine is

to be set up for immediate severe duty such as drag racing or other

competition application. See Piston Fit Specification chart below.

1. For maximum piston and ring life, fit pistons using close fit

dimensions. Close fit requires absolute adherence to new engine

break-in as described in Step 6.

2. For immediate drag strip use, fit pistons using loose fit dimensions.

Break in rings and pistons with 50 easy miles if possible. Piston

and ring life will be reduced with loose fit dimensions.

3. Measure all pistons at widest point across thrust face,

perpendicular to wristpin hole. Several measurements should be

taken to locate widest point. Typically, this will be at bottom of

piston skirt, and approximately 1⁄2" below level of wristpin hole.

4. S&S® recommends #220-#280 grit stone for final honing of S&S

bore cylinders.

5. Follow procedure recommended in Harley-Davidson® service

manual for boring and honing S&S cylinders, or follow instructions

included with S&S Cylinder Torque Plate Kit. Torque plates must

be used to simulate compressive stress in an assembled engine.

Cylinders will distort if torque plates are not used.

CAUTION

Failure to follow instructions and perform required clearancing,

installation and/or break-in procedures may result in damage

to pistons and/or other engine components not covered under

warranty.

4

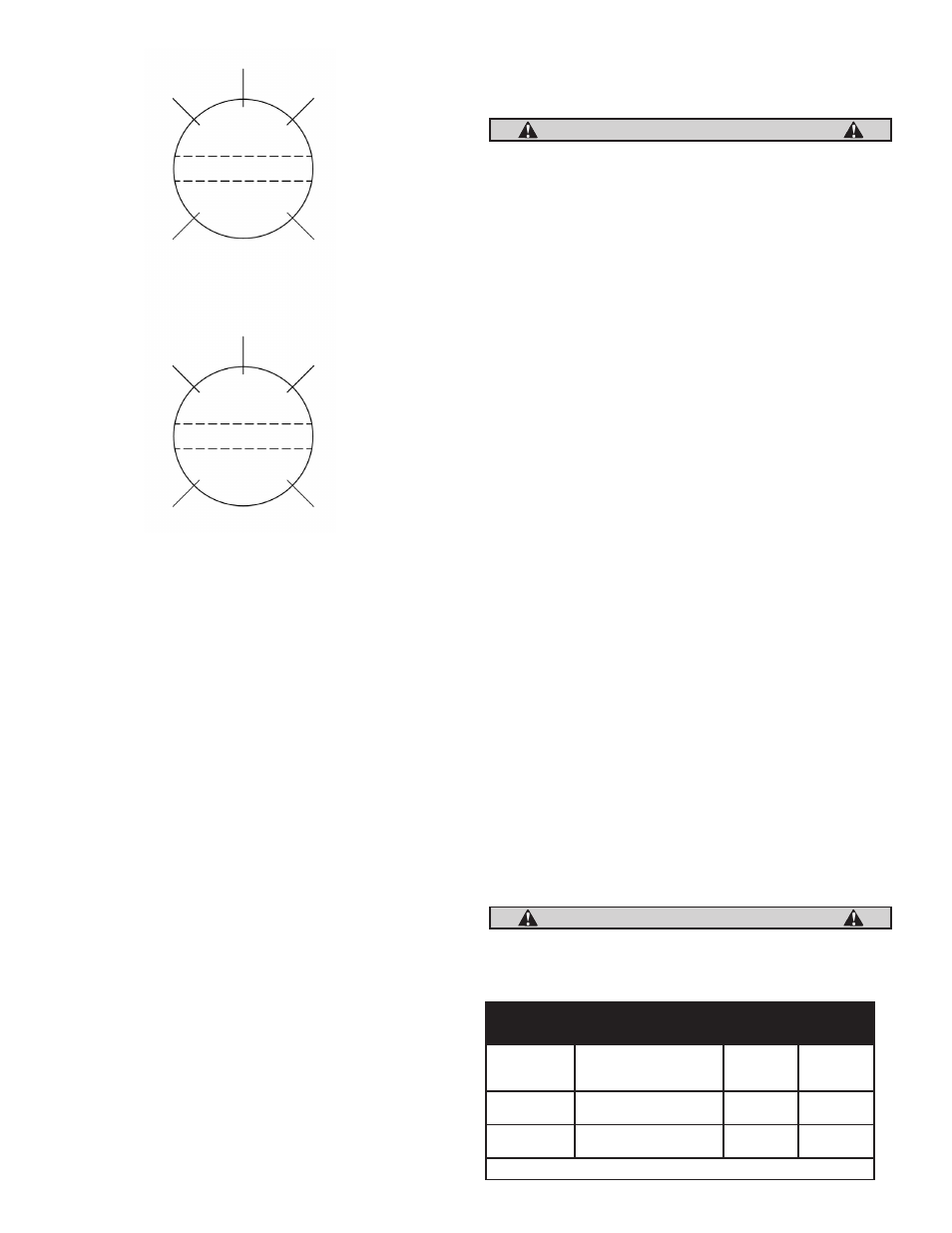

EXPANDER GAP

FRONT PISTON

REAR PISTON

SECOND COMPRESSION

RING GAP

TOP RAIL GAP

BOTTOM RAIL GAP

TOP COMPRESSION

RING GAP

SECOND COMPRESSION

RING GAP

EXPANDER GAP

TOP RAIL GAP

BOTTOM RAIL GAP

TOP COMPRESSION

RING GAP

Figure 5: GAP PLACEMENT ILLUSTRATION

PISTON FIT SPECIFICATIONS

PART #

DESCRIPTION

CLOSE FIT

LOOSE FIT

106-5548 – STD

106-5549 – +.010"

106-5550 – +.020"

883 TO 1200 CONVERSION PISTON

1986-UP XL 31⁄2" BORE DISHED

DOME

.0025" TO.0030"

0035" TO.0045"

920-0070

1250CC PISTON 1986-UP XL

39/16" BORE FLAT DOME

.0025" TO.0030"

0035" TO.0045"

920-0071

1250CC PISTON 1986-UP XL

39/16" BORE 5.5CC RAISED DOME

.0025" TO.0030"

0035" TO.0045"

*NOTE: FIT WRISTPINS AT .0007" TO .0014".