S&S Cycle Piston and Cylinder Kits for all 1986-up Harley-Davidson Sportster Models User Manual

Page 2

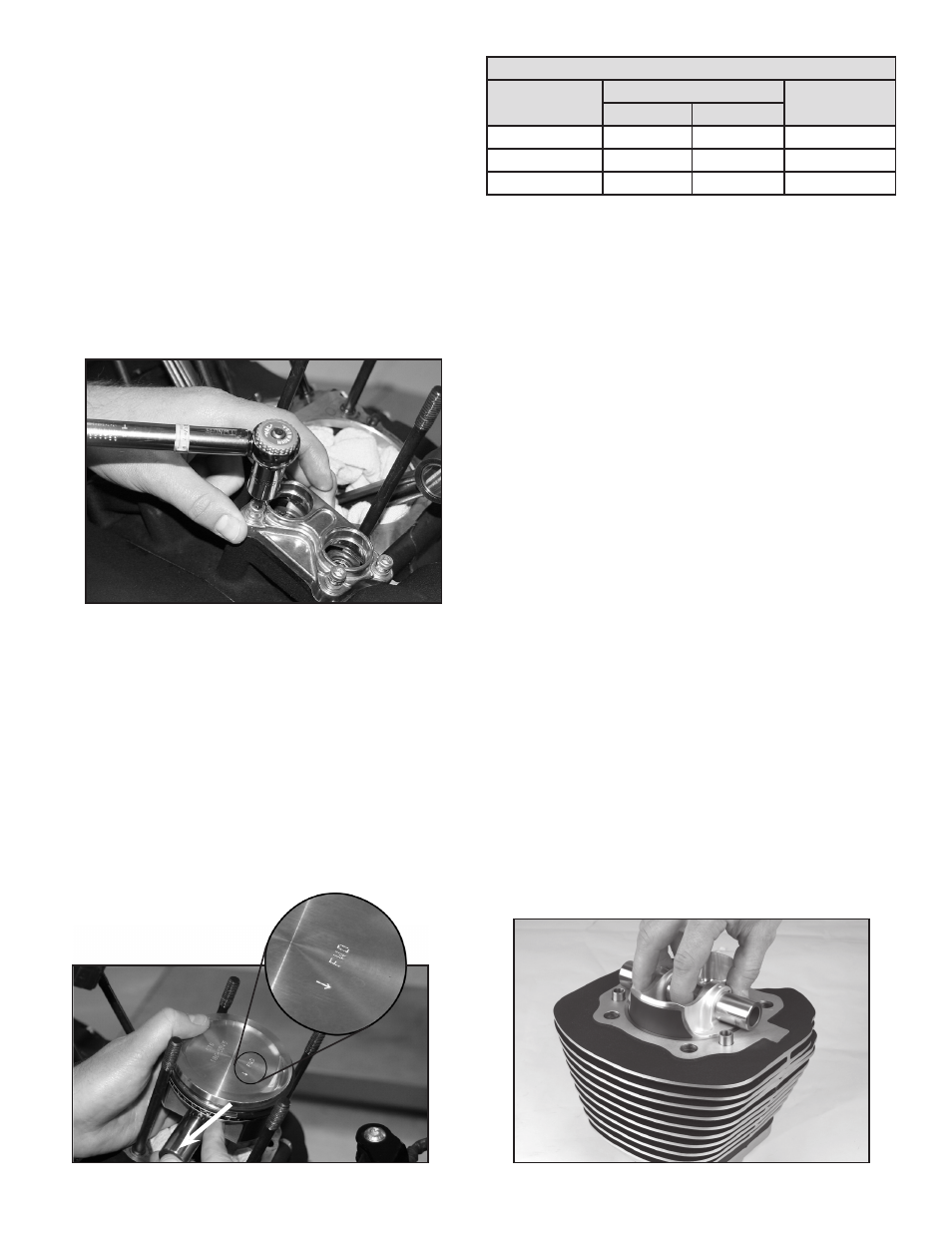

1. Remove the cylinder heads, cylinders, and pistons according to

the procedures in the Harley-Davidson® service manual.

2. For 2004-up models – prior to installing the new S&S pistons

and cylinders, move tappet covers as far as possible to toward

the outside of the engine (away from the cylinders) to ensure

adequate clearance between the tappet covers and cylinder

bases.

a. Remove tappet covers from crankcase

b. Clean tappet covers, reusable gaskets, crankcase gasket

surface, and hardware with solvent and a clean rag.

c. Apply blue thread locking compound to tappet cover screws.

d. Reinstall tappet cover gaskets, covers, and screws, but do not

final tighten.

e. Hold the tappet cover as far away from the cylinders as

possible. See Picture 1, below.

f. Torque screws to 120 In*lb in a criss-cross pattern.

3. Install S&S Pistons

NOTES:

• These S&S piston scan be used in either the front or rear position.

However, when purchased in a kit with cylinders, each piston must be

kept with the cylinder it was delivered in, as each cylinder is individually

honed to fit a specific piston.

• Rebalancing is not required when installing this kit.

a. Clean pistons and wrist pins with solvent.

NOTE: Wristpin must be thoroughly cleaned before installation, paying

particular attention to bore. Pass clean, lint-free cloth back and forth

through wristpin bore several times to insure removal of all contaminants.

b. Apply assembly lube to connecting rod bushings, wristpins,

and piston wristpin holes.

c. Install pistons with the FWD arrow mark pointing toward the

front of the engine. See Picture 2, below, left.

d. Ensure that wristpin clip groove in piston is free of burrs

and foreign matter. Install wire clips using procedure

recommended in a Harley-Davidson® service manual. End

of clip must rest over notch in piston below wristpin hole to

allow removal of clip in future. Be sure clip is fully seated in

groove.

NOTE: Round “wire” style clips supplied with this kit are identical to and

interchangeable with stock clips in Harley-Davidson® Evolution® engines.

4. Install Piston Rings

NOTE: Ring widths on some piston series may change from time to time.

Part numbers of rings originally supplied with pistons should be recorded

for future reference in the event replacement rings are required.

a. Measure ring end gap by pushing ring about 1 inch into the

cylinder bore from the head end of the cylinder, using the

piston to insert the ring squarely in the bore. See Picture 3,

below. Measure the gap between the ends of the ring with

a feeler gauge. See Picture 4, next page. Compression ring

end gap should be between .016" to .026". Oil ring rail end

gap should be between .010 to .050". If there is insufficient

ring end gap, file the end of the piston ring to achieve the

desired gap. Ends of piston ring must be deburred after filing.

b. Thoroughly clean the piston rings after filing and deburring

and install on pistons.

2

Picture 3

Picture 1

Suggested ring end gaps

Ring

Ring Gap Tolerance (inches)

Target Gap

Min

Max

Top

0.016

0.022

0.017

2nd

0.016

0.026

0.021

Oil ring rails

0.010

0.050

0.010 to 0.050

Picture 2