Caution – S&S Cycle High Performance Valve Spring Kits 90-2079, 90-2080 and 90-2081 User Manual

Page 2

S&S

®

valve spring and collar kits 90-2079, 90-2080 and 90-2081 are

designed for street and race applications that utilize camshafts

with extremely high lifts requiring higher than normal spring

pressures. These kits are intended primarily for use on S&S Special

Application heads. .660-lift kit 90-2079 can also be used on S&S

Street Heads normally supplied on S&S engines, or any other

head which can accept a 1.650” outer spring O.D.

NOTE - Kit 90-2079 is a “bolt-in” installation for earlier S&S street

heads equipped with .630” high-lift option that utilizes .085”

longer valves. See following paragraph for part numbers. It

remains the engine builder’s responsibility to confirm all

measurements and clearances during installation.

Kits are designed for “no shoulder” valve guides. Keepers fit

stock

5

⁄

16

” diameter valves and supplied titanium collars or exact

replacement only. In S&S street heads, .660-lift kit requires use of

.085” longer valves 90-2004 (intake) and 90-2005 (exhaust). All

kits are compatible with S&S 90-2013 (intake) and 90-2012

(exhaust) valves supplied with Special Application heads.

Because of special assembly procedures required with high-lift

camshafts and related parts, S&S recommends that these parts be

installed by a professional mechanic having considerable

experience with parts of this nature.

●

Improper assembly including failure to establish proper

measurements and clearances can cause extensive engine

damage which is solely the responsibility of the installer.

●

Mixing valves, springs, collars, keepers or other parts from

different valve spring kits can cause extensive engine

damage which is also the responsibility of the installer.

NOTE - S&S valve spring kits 90-2079, 90-2080 and 90-2081

feature triple valve springs. 90-2079 and 90-2080 utilize flat

middle spring. 90-2081 has round middle spring.

Spring Installation Procedure

1.

If applicable, remove cylinder heads from engine and

disassemble. If cylinder heads/valves are to be reconditioned,

proceed according to standard procedure at this time. Refer

to appropriate service manual or consult professional

mechanic as needed.

2.

Place lower spring collar in valve spring pocket in head.

Place outer spring on collar. Collar must rest flat on head

and spring coils must not contact sides of spring pocket in

head. If necessary, machine lower collar and/or spring

pocket to obtain minimum clearance of .030”. Do not

modify spring in any way.

3.

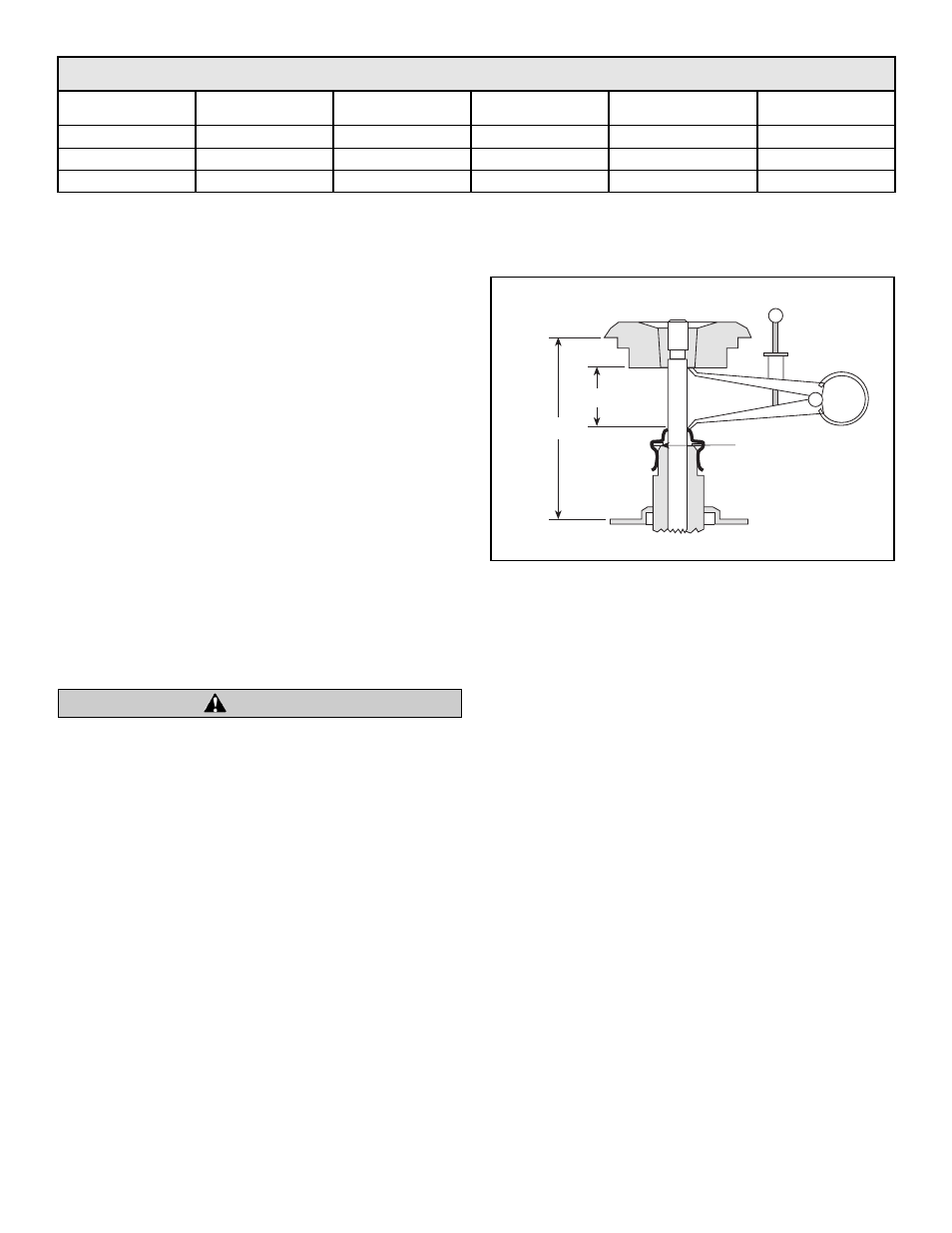

Using following procedure, determine installed spring

height and clearance between top collar and valve guide.

A.

Lubricate valve stem and install valve in guide.

B.

Install bottom collar, valve guide seal, top collar and

valve keepers. Pull top collar tightly against keepers to

seat keepers in collar.

C.

While holding valve firmly against seat in closed

position, measure installed spring height (distance

between lower valve spring seating surface and outside

step of top collar). See Figure A, Dimension A. Record

measurement.

D.

Measure distance between top collar keepers and top of

valve guide or seal (if applicable). See Figure A,

Dimension B. Distance must be at least .060” greater

than valve lift of cam to be used. If distance is less, valve

guide must be shortened to obtain required clearance.

E.

Repeat Steps A-D for remaining valves and record all

measurements. Label and keep track of all parts during

assembly to insure they are installed in same location

and with same valves that measurements were

obtained with.

4.

Adjust installed spring heights to dimension shown in

specifications table above. If installed height is too high,

place shims under lower collar to achieve correct height.

Shims are available from S&S and local sources such as

automotive parts houses. If spring height is too low, grind

valve or valve seat or machine spring floor in cylinder head

to achieve correct height.

2

SPECIFICATIONS

Part Number

Maximum Lift

Installed Height

Seat Force

Force @ Maximum Lift

Coil Bind Height

90-2079

.660”

1.900”

210 lbs.

520 lbs.

1.130”

90-2080

.720”

1.975”

250 lbs.

625 lbs.

1.175”

90-2081

.800”

2.000”

285 lbs.

790 lbs.

1.140”

CAUTION

Remove seal and grind

guide here to obtain

greater measurement B.

B

A

Figure A

Dimension A: Installed spring height must be

adjusted to above specification + /- .020”

Dimension B: Must be .060” greater than valve lift for camshaft to be used.

Remove seal and grind

guide here to increase

dimension B.