Caution – S&S Cycle Chain Drive Camshaft Set for Harley-Davidson Twin Cam 88 Engines User Manual

Page 6

4.

Apply thin film of assembly lube to bearing surface of

S&S

®

camshafts and inner race of cam bearings in cam

plate. Support bearings by inner race. Using tool H-D

®

#43644, align both cams with bearings, install into cam

bearings by pressing on front cam only, guide slip-fit

rear cam into bearing. See Picture 10.

5.

Install new retaining ring in groove at end of front cam.

6.

Remove cam needle bearings from crankcase with tool

H-D #42325 and replace with new bearings provided in

S&S installation kit 33-5175 or obtained from other

source. Lubricate with clean engine oil.

7.

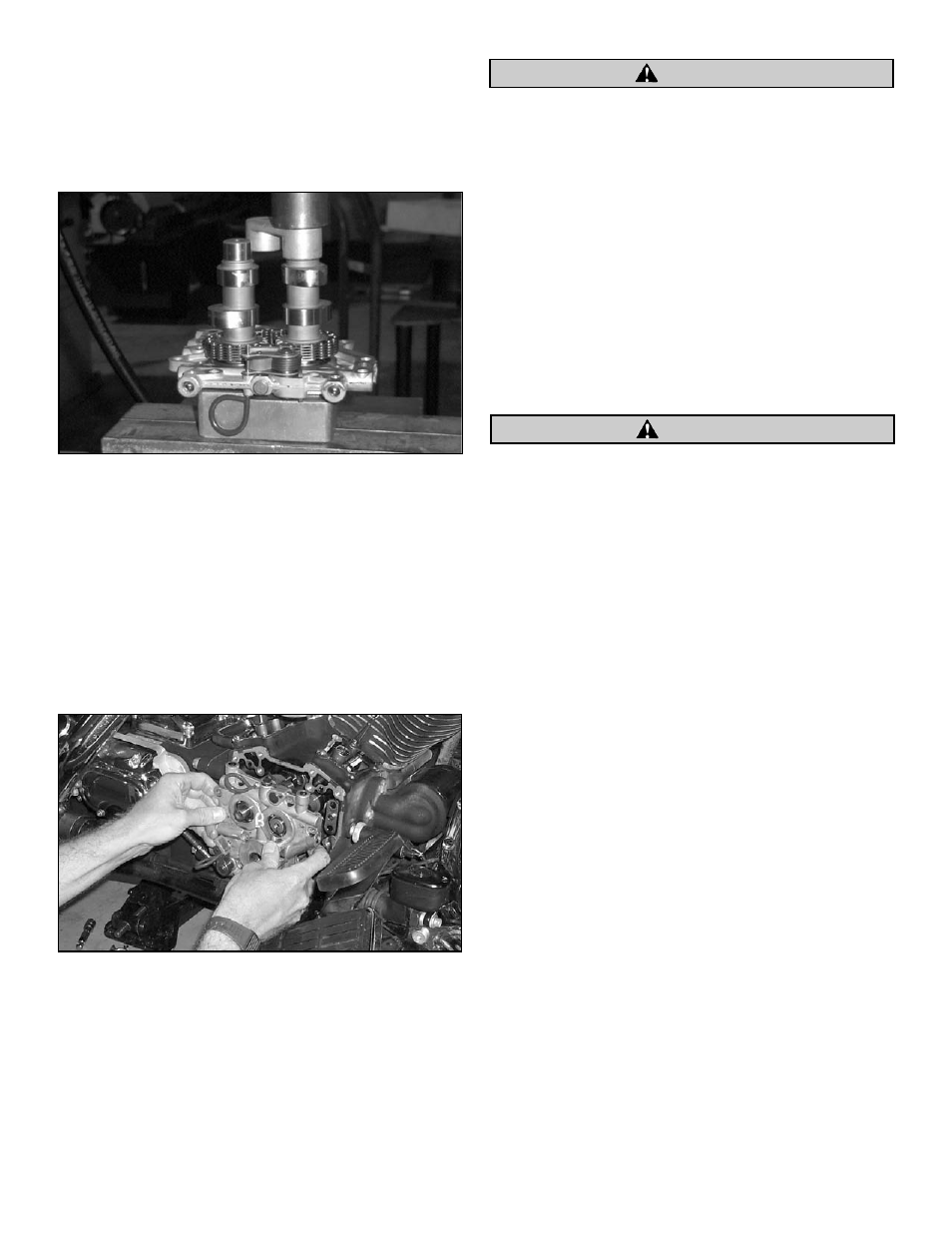

Apply thin layer of assembly lube to cam journals and

lobe surfaces. Align cams with needle bearings and

carefully slide support plate assembly over crankcase

dowels. See Picture 11.

8.

Apply Loctite

®

243 (blue) to six support plate screws,

install screws, and gradually tighten to 95 in-lbs. in

sequence illustrated in Figure 2 on page 4.

NOTE - Support plate assembly should slide into place without

resistance. If resistance is encountered, determine cause before

proceeding. Do not force plate assembly!

S&S has stripped holes for support plate screws when using

maximum 120 in-lb. maximum torque spec recommended by

Harley-Davidson

®

. Holes stripped are those which pass

through alignment dowels, Positions #1 & #2 in Harley-

Davidson diagram of Cam Support Plate/Oil Pump Torque

Sequence.

9. Apply

Loctite

®

#243 (blue) to threads and reinstall four

oil pump bolts according to following procedure:

a.

Gently bottom screws, then back out

1

⁄

4

turn.

b.

Center pump by rotating engine while

snugging screws.

c.

Rotate engine by turning rear wheel (see Section B

securing motorcycle).

d.

Tighten bolts to 90-120 in-lbs. in sequence

illustrated in Figure 1 on page 4.

Do not use primary cam sprocket or crank sprocket bolt heads

to rotate engine.

10. Carefully remove secondary cam tensioner retaining pin.

11. Check front to back alignment of outer drive sprockets.

a.

Place rear cam sprocket spacer next to rear

bearing race.

b.

Install rear camshaft and crankshaft sprockets.

c. Temporarily install crankshaft and camshaft

sprocket bolts. Temporarily use a smaller diameter

washer under the head of the crankshaft bolt. (This

will allow a straightedge to fit on the sprocket face

for Steps 13 d and e.)

d. Torque crankshaft and rear camshaft sprockets to

25 ft-lb. do not use Loctite

®

at this time.

e. Push on rear camshaft to remove end play.

f. Place a straightedge across the cam and

crankshaft sprockets

g. Try to slide a .010” thick feeler gauge between the

straightedge and each sprocket face. If the feeler

gauge does not fit at either location, the front to

rear alignment of the sprockets is correct. In most

situations, re-using the original crankshaft and

camshaft sprockets, the alignment will be correct.

Mis-alignment is generally because a different

camshaft sprocket is used at re-assembly. In cases

where the alignment front to back is not within

.010”, spacing washers are available from the OEM

or aftermarket sprocket manufacturer to align the

gears. Gear alignment must be within .010” before

proceeding.

h. After verifying correct sprocket spacing, remove

camshaft and crank sprocket bolts, remove both

sprockets, and discard smaller diameter washer

used under head of crank sprocket during

alignment check.

6

CAUTION

CAUTION

Picture 10

Picture 11