Caution – S&S Cycle Chain Drive Camshaft Set for Harley-Davidson Twin Cam 88 Engines User Manual

Page 4

6.

Use tool H-D

®

#42313 (Cam Chain Tensioner Unloader)

to swing primary cam chain tensioner away from chain.

Secure with retention pin. See Picture 5.

Do not pull the retention pins from the primary or secondary

cam chain tensioners when the chain and sprockets are

removed! The primary and secondary cam tensioner springs

exert 35-40 pounds of pressure when retained. Removing a

retaining pin without supporting the shoe will cause the

spring to snap open through its full travel, damaging it,

and/or the tensioner shoe. The tensioner can also injure

hands and fingers in its path.

NOTE - If cam chain tensioner retaining pins interfere with

cleaning or service procedures when the cam support plate is

removed, use cam chain tensioner unloader tool (H-D #42313) to

hold against spring pressure, then remove retaining pin and ease

spring assembly into the unloaded position.

7.

Working gradually around edge of sprocket, carefully

pry sprockets off cams until loose on shaft. Remove

sprocket/chain assembly and mark chain with magic

marker to indicate direction of travel. Chain should be

reinstalled in same direction.

8.

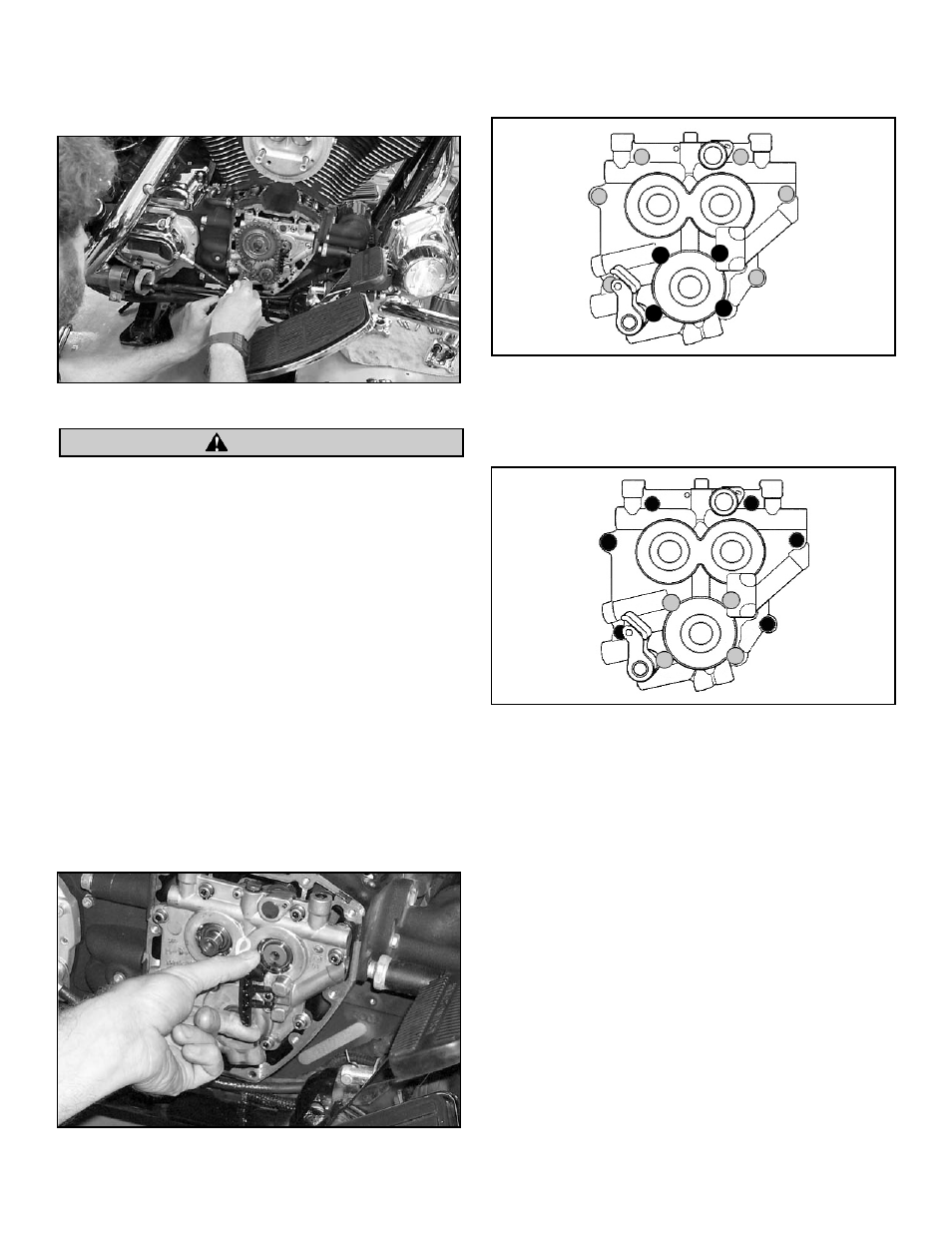

Remove chain guide. See Picture 6.

9.

Gradually loosen and remove four oil pump bolts

according to sequence shown in Figure 1.

10. Gradually loosen and remove six support plate bolts

according to sequence shown in Figure 2.

NOTE - Failure to remove or install bolts according to correct

procedure may result in parts damage not covered under

warranty.

11. Carefully remove cam support plate assembly from

crankcase. Use tool H-D #42313 to swing secondary cam

tensioner away from chain. Secure tensioner with

second retention pin inserted through front of support

plate. Do not remove pin until support plate assembly

has been reinstalled in engine.

NOTE - It is not necessary to remove oil pump from engine to

complete installation. However, installer must insure that oil

pump O-rings are in good condition and remain in place during

procedure. It is installer’s responsibility to replace O-rings if

necessary.

12. Remove screws that secure bearing retainer to support

plate and remove retainer from plate.

4

Picture 6

Figure 1

4

2

3

1

Figure 2

1

5

3

6

2

4

Picture 5

CAUTION