S&S Cycle Die-Cast Rocker Covers for 1984–99 and 1999–14 Harley-Davidson Big Twin Engines and S&S V-Series and T-Series engines User Manual

Page 4

2. Start two 5/16-18 x 21⁄2 hex head bolts in right (cam side) rocker

support holes to temporarily hold cam-side rocker housing

gasket in position. Install two remaining rocker housing screws.

Gradually tighten four 1⁄4-20 x 3⁄4 screws to 10-13 ft.-lbs. Remove

hex head bolts.

3. Measure clearance between rocker housing and valve spring. See

Picture 5, above. Minimum is .025". If necessary, loosen screws

and reposition housing to increase clearance, then retighten

screws.

4. Place new o-ring in center of rocker housing.

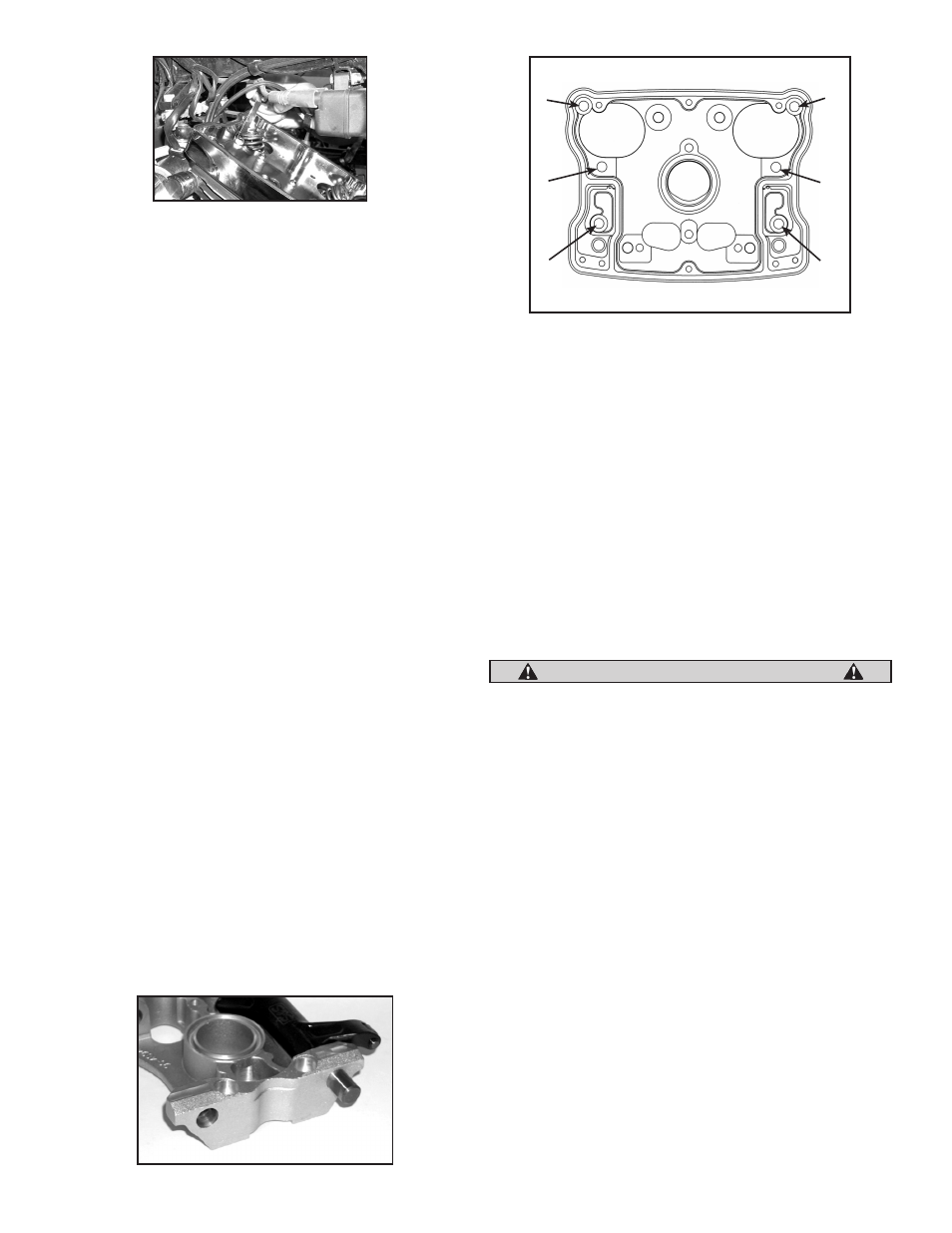

10. Inspect rocker shafts for burrs and excessive wear; deburr or replace

as necessary. Lubricate rocker shafts with assembly lube, place

rocker arms in support, and slide shafts through supports and rocker

arms. Notches in shafts must face away from center of engine and

align with right (camside) bolt holes. See Picture 6, below.

11. Check rocker arm endplay by sliding rocker arm as far to one side

as possible and measuring gap between rocker arm and support

on opposite end. Acceptable endplay is .001" to .012". If endplay

is insufficient, carefully remove material from end of rocker arm to

achieve correct endplay. Smooth out the area where material was

removed. Clean the rocker arm thoroughly to remove any residual

abrasive or metal particles before installing in engine.

12. Prepare rocker support bolts according to instructions on Loctite®

container and apply thin film of Loctite® to threads. Insert two 5/16-18

x 21⁄4" socket head bolts and washers in holes in left (drive) side of

support and two 5/16-18 x 21⁄2" hex head bolts in holes in right (cam)

side of support.

13. Place rocker arm support assembly with rockers in rocker housing.

Align pushrod ends with sockets in rockers and gradually tighten

four support bolts to 15-18 ft-lbs. according to sequence shown. See

Figure 1, page 3.

14. Install remaining rocker support bolt(s).

A. 1999-up engines: Prepare one 1/4-20 x 1 socket head bolt and

one 1/4-20 x 2 socket head bolt for Loctite® and apply thin film of

Loctite® to threads. Install Part #50-7017 .425" diameter washer on

the 1/4-20 x 1 bolt, and install Part #50-7020 .475" diameter washer

on the 1/4-20 x 2 bolt. Insert 1/4-20 x 1 bolt with washer in center left

side of support and 1/4-20 x 2 bolt with washer in center right side

of support. Tighten both to 10-13 ft-lbs.

B. 1984-'99 engines: Prepare one 1/4-20 x 2 socket head bolt for

Loctite® and apply thin film of Loctite® to threads. Install Part #50-

7020 .475" diameter washer on bolt and insert bolt with washer in

center right hole of support. Tighten to 10-13 ft.-lbs.

NOTE: Hydraulic lifters may take 5-10 minutes to bleed down after rocker

assembly is installed. Do not rotate engine until pushrods can be turned

with light finger pressure.

CAUTION

Rotating engine before lifters have bled down can cause extensive

engine damage.

15. Confirm clearance between rocker arm and top rocker cover

by applying layer of clay at least .060" thick to areas of cover that

rocker arms will come closest to at maximum lift. Temporarily install

covers with four screws and rotate engine through two complete

revolutions. Carefully remove covers and examine clay. Layer of

clay above rocker arm must remain at least .060" thick. If dented,

indentation must leave at least .060" of clay between rocker arm

and cover. Remove clay and thoroughly clean rocker and cover with

clean, lint-free cloth.

16. Place rocker cover seal and o-ring in position on rocker housing.

17. Install one flat and one fiber washer on each of six 1⁄4-20 x 3⁄4 rocker

cover screws.

NOTE: Install flat washer on screw first. Fiber washer goes between flat

washer and rocker cover.

18. Install rocker cover and gradually tighten screws to 90-100 in-lbs. in

sequence shown. See Figure 3, next page.

19. After confirming that pushrods turn with light finger pressure,

extend pushrod tubes and replace retainer clips.

4

Picture 5

Picture 6

Figure 2

camside

driveside

fro

nt

2

3

6

5

4

1