S&S Cycle Die-Cast Rocker Covers for 1984–99 and 1999–14 Harley-Davidson Big Twin Engines and S&S V-Series and T-Series engines User Manual

Page 2

Introduction

S&S® die-cast rocker cover kits for Harley-Davidson® Evolution® engines

(1984-'99) and Twin Cam 88®, 96™ and 103™ engines (1999-2014) are

similar, but not identical. Mounting holes are larger in the bases for

1999-2014 engines and in slightly different locations. Because of the

different vent systems and mounting-bolt patterns, different rocker

housing bases and rocker housing base gaskets are required for the two

engines.

All S&S V-Series engines for 1984-’99 models, except 41/8" bore, require

1984-’99 style rocker cover kit. S&S 41/8" bore V-Series engines require

1999-’14 style rocker covers. Make sure you have the correct rocker

cover kit, and follow the appropriate installation procedure.

Removal of existing rocker covers and installation of S&S die-cast covers

is similar for 1984-’99 and 1999-2014 engines. Steps 4, 7, and 9 detail

procedures or components for required for both engine types. Where

applicable, procedures and illustrations are clearly designated for each

engine type. Otherwise, installations for both engines are identical. S&S

recommends that the installer become thoroughly familiar with the Top

End Overhaul Procedure section in an appropriate Harley- Davidson®

service manual and refer to this section as required.

S&S wrench set 53-0040 will prove helpful when installing S&S rocker

covers. As an alternative, conventional Allen wrenches can be shortened

by grinding. Otherwise, the motorcycle frame may interfere with the

tightening of some fasteners. S&S strongly recommends the use of a

torque wrench and Loctite® 242 (included) on all fasteners.

S&S rocker covers accept valve springs up to 1.660" O.D. with no

modification. In most instances, they will accept valve lifts to .710"

without modification. It remains the installer’s responsibility to confirm

all clearances. For your own protection and to prevent damage to your

motorcycle during the installation, thoroughly familiarize yourself with

these instructions before proceeding.

NOTES

• Threads should be cleaned with Loctite® primer or an equivalent before

applying Loctite®. S&S has used lacquer thinner with excellent results.

• The installer must check clearances between the valve spring/top

collar and rocker cover housing as well as between the rocker arm and

top cover. These procedures are described in Steps 10 and 16.

CAUTION

Failure to establish correct clearances can result in extensive engine

damage not covered under warranty.

It is the installer’s responsibility to use Loctite according to

directions printed on the container, and to tighten fasteners to

correct torque values. Failure to install fasteners correctly may

result in the fastener vibrating loose and causing extensive engine

damage not covered under warranty.

WARNING

Gasoline, lacquer thinner, and many solvents are extremely

flammable. Fumes may be explosive and toxic if inhaled. Read and

follow the manufacturers’ instructions if applicable, and use these

materials only in a well ventilated area away from sparks and open

flame.

Installation

1. Prepare for rocker cover installation by washing motorcycle, taking

special care to remove dirt from engine and surrounding area.

Disconnect battery, ground cable. Remove gas tanks and clean

engine and surrounding area with compressed air.

CAUTION

Dirt and other contaminants can cause extensive damage if allowed

to fall into engine.

WARNING

Sparks from motorcycle electrical system can ignite gasoline

fumes, resulting in an explosion. Removing battery eliminates

the possibilities of explosion and injury arising from inadvertent

activation of the electric starter.

High-pressure air is potentially hazardous. Wear eye protection

during use and direct air stream away from face and others nearby.

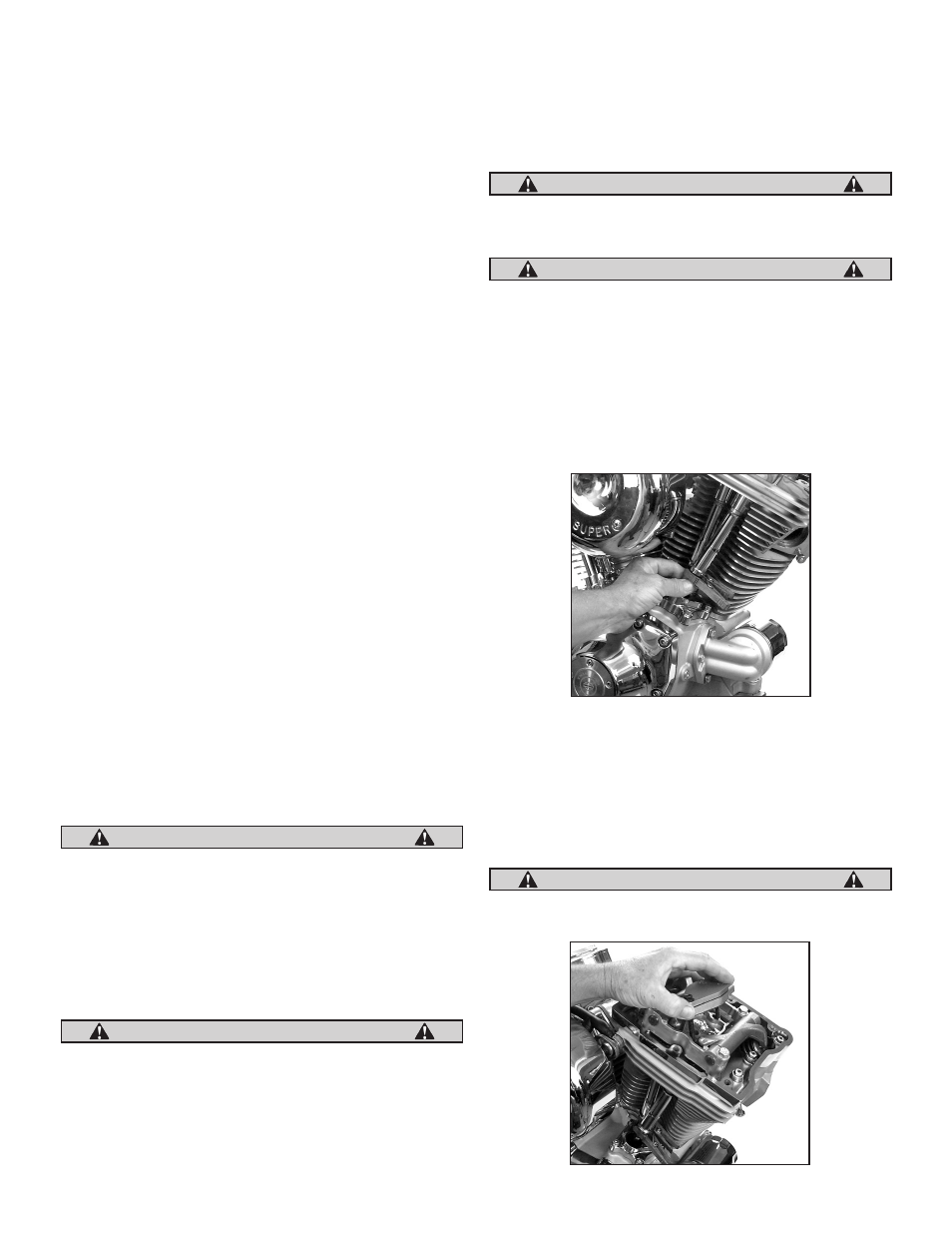

2. Remove original top rocker cover. Remove pushrod cover retainers

from front cylinder pushrods and collapse pushrod covers.

3. Lift the rear wheel of the motorcycle with a jack. remove sparkplugs,

place motorcycle in fifth gear, and turn wheel to rotate engine and

place intake and exhaust pushrods/lifters for front cylinder at their

lowest point of travel. Front piston will be at TDC on compression

stroke with pushrods/lifters at lowest point. Confirm that both

pushrods can be rotated with light finger pressure. See Picture 1.

CAUTION

Failure to confirm correct pushrod position can result in damage to

rocker arm support plates and other parts.

2

Picture 1

Picture 2