General – Retsch SR 300 User Manual

Page 17

2/8/2012

Retsch GmbH

17

0002

General

Cleaning

SR 300

Fig. 14

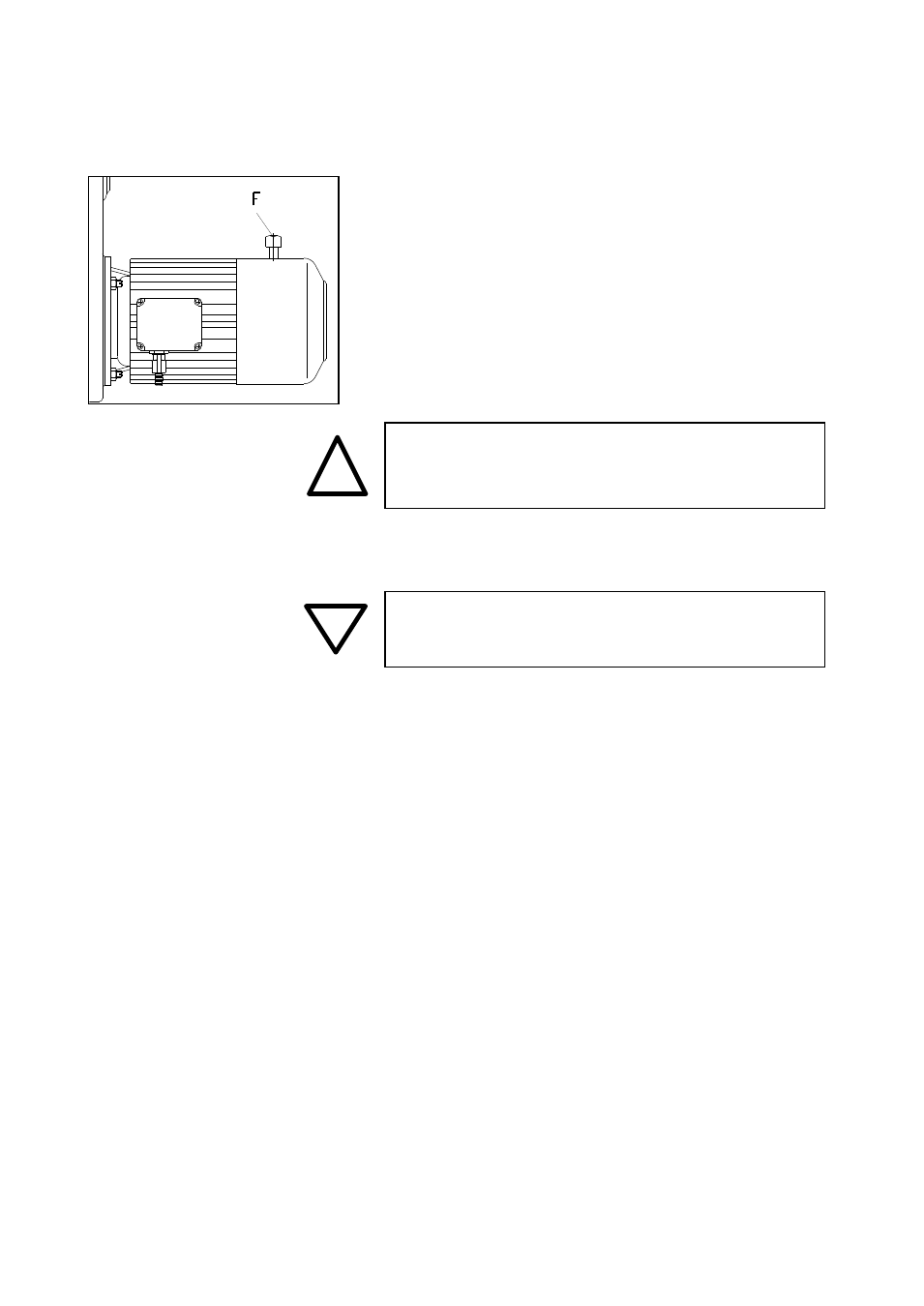

The grinding chamber in the SR 300 can be cleaned with a brush and,

if necessary, an industrial vacuum cleaner and compressed air.

The motor brake can be released to facilitate cleaning the SR 300

grinding chamber; use lever F (Fig. 14) to do so. The rotor-beater can

now be turned easily, thus simplifying 0cleaning.

The SR 300 is engineered to IP 54 safety standards.

!

Never clean the SR 300 with running water.

Hazard of fatal electrical shock.

Sieves, grinding inserts and rotors

Once they have been removed from the SR 300, these items can be

cleaned under running water or in an ultrasonic bath.

Dry all wet parts thoroughly after cleaning.

Rust can form on wet components.

Maintenance

The SR 300 is largely maintenance-free.

Required inspections

The limit switches and the motor brakes are to be checked twice a year

for proper operation.

Limit switch on the left, at the door hinge

The limit switch must shut down the motor at a maximum opening

gap of 3 mm.

Limit switch on the right, at the quick-acting catch

The motor brakes must engage when the hand wheel is turned by a

maximum of 45°.

Motor brakes

Start the SR 300.

Stop the SR 300.

Use a stopwatch to time the braking period.

If the braking period should exceed 1.5 seconds, then contact the

authorized service technicians.