Instructions for use – Retsch SR 300 User Manual

Page 16

2/8/2012

Retsch GmbH

16

0002

Instructions for use

Target group: Laboratory personnel

General

The SR 300 is a modern, high-performance product manufactured by

the Retsch GmbH.

A broad selection of accessories makes the SR 300 rotor-beater grind-

ing mill a versatile device suitable for a wide range of applications,

principally in chemicals and pharmaceuticals, in mineralogy and biolo-

gy, etc., and in industrial and research laboratories.

The SR 300 is used primarily for preliminary and final pulverization of

dry, soft to medium-hard materials of up to about 4 on the Mohs

hardness scale.

Ultimate fineness

The ultimate fineness which can be achieved is dependent on the size

of the sieve openings and the fracture characteristics of the pulveriza-

tion product. In favorable cases fineness of < 60 µm can be attained.

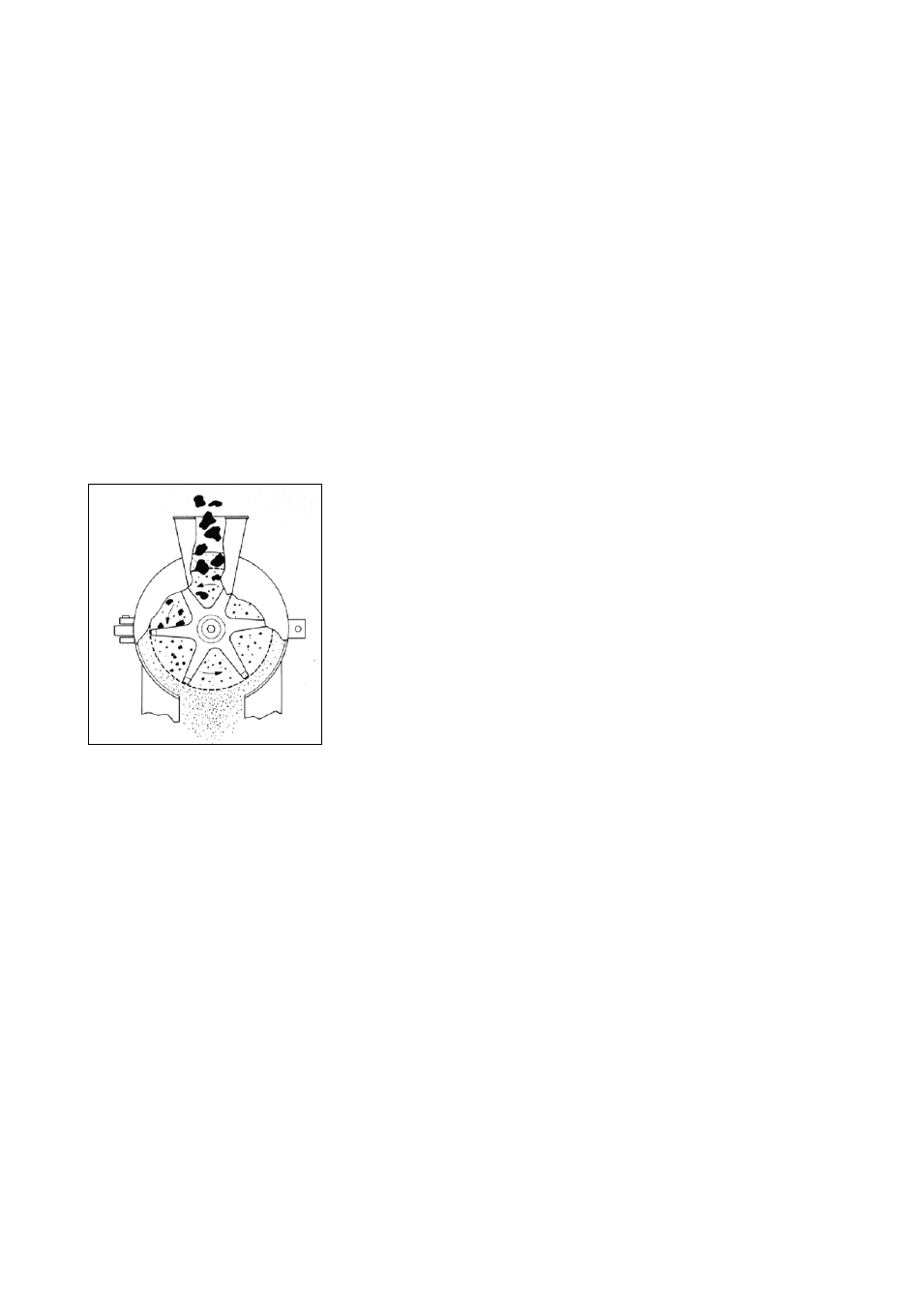

Operating principle for the SR 300

Operating schematic

Pulverization in the SR 300 rotor-beater mill is effected by impact, re-

bound and shear action.

Once it has been introduced into the feed hopper, the product passes

into the grinding chamber where the size reduction process takes place

between the rotor-beater, the grinding insert and the sieve. See also

the operating schematic.

Once the product has achieved the appropriate ultimate fineness it

passes through the sieve and into the collection receptacle.

Using a cloth filter bag or a Conidur filter (optional accessory) mount-

ed between the SR 300 and the collection receptacle, the air stream

generated by the rotor-beater as it turns will be deflected and routed

downward toward the material discharge. In addition it will increase the

material throughput rate and ensures that the solids portion in the air

stream will be separated out.