Wooden floor, Purusline living wetroom solution – Purus Living 600 - Drop/Twist Grate User Manual

Page 7

7

PURUSLINE LIVING WETROOM SOLUTION

Wooden floor

02835

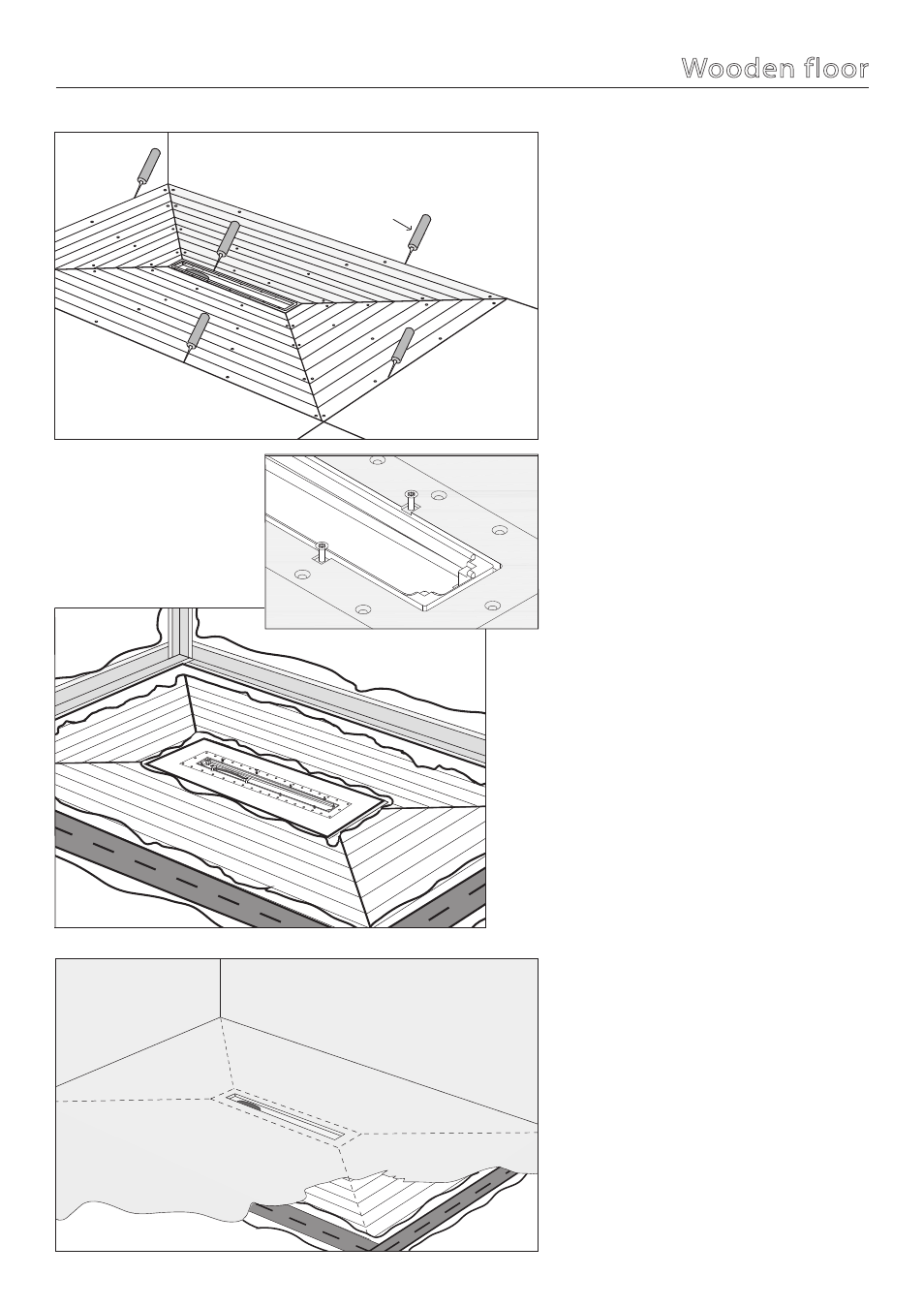

Stage 8

Now cover the whole tray, tapes, gasket, walls and

floor with one coat of Puragum and allow to dry for

another 3 hours, then apply a second coat. Ensure

the Puragum goes up to the edge of the gully groove

ensuring you overlap the gasket with the two coats of

Puragum, then leave to dry for a minimum of 24 hours

before tiling depending on site conditions.

Once the second coat of Puragum has fully

cured, check the tapes and gasket are fully

secure and sealed before tiling.

Ensure the tanking kit is installed as per the

instructions. Ensure you follow the tanking kit

instructions and that the tapes and membranes are

fully secure before tiling.

Ensure you keep to the minimum drying times.

Drying times could be longer depending on site

conditions.

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

Puragum

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

18mm Marine Ply

18mm Marine Ply

MS Polymer

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

Stage 6

Level the floor with 18mm marine plywood (not

supplied) or appropriate tile backer boards. Fix the

18mm marine plywood or tile backer boards to the

floorboards in accordance to BS5385 for ceramic tiles.

Ensuring you avoid screwing through any pipework,

cables etc.

Then totally fill the following gaps with the MS

Polymer, smoothing down as you go along and

ensuring that all the gaps are fully sealed:

1). between the gully and the tray;

2). between the tray and walls;

3). between the tray and floor.

Then allow a minimum of one hour for the MS Polymer

to tack over before applying the tapes and gasket.

Stage 7

Place the gasket around the gully to check if it fits.

Take the Pura Elastomeric Tapes and dry cut to the

tray, floor, walls and board joints.

Once the MS Polymer has tacked over, using a brush

or roller apply the Puragum to all wall, floor and tray

joints one at a time. Apply the Pura Elastomeric Tapes

while the Puragum is still wet, firmly smoothing down

the tape as you go so there are no air pockets or ridges

left and the tapes are fully adhered.

Leaving the height adjusting screws in their holes,

apply the Puragum up to the edge of the groove of the

gully ensuring you have enough Puragum to overlap

the gasket.

Then fix the gasket with Puragum whilst still wet,

ensuring that the whole gasket is overlapped

underneath with Puragum. Ensure the gasket is

centred. Firmly smooth down the gasket and tapes so

there are no air pockets or ridges left and the gasket is

fully adhered.

Now allow to dry for 3 hours.