Technical characteristics – Northern Connectors Harting Har-flex PCB Connectors User Manual

Page 4

14

04

har

-flex

15

. .

. . .

. . .

2 . . .

15

. .

. . .

. . .

6 . . .

15

. .

. . .

. . .

5 . . .

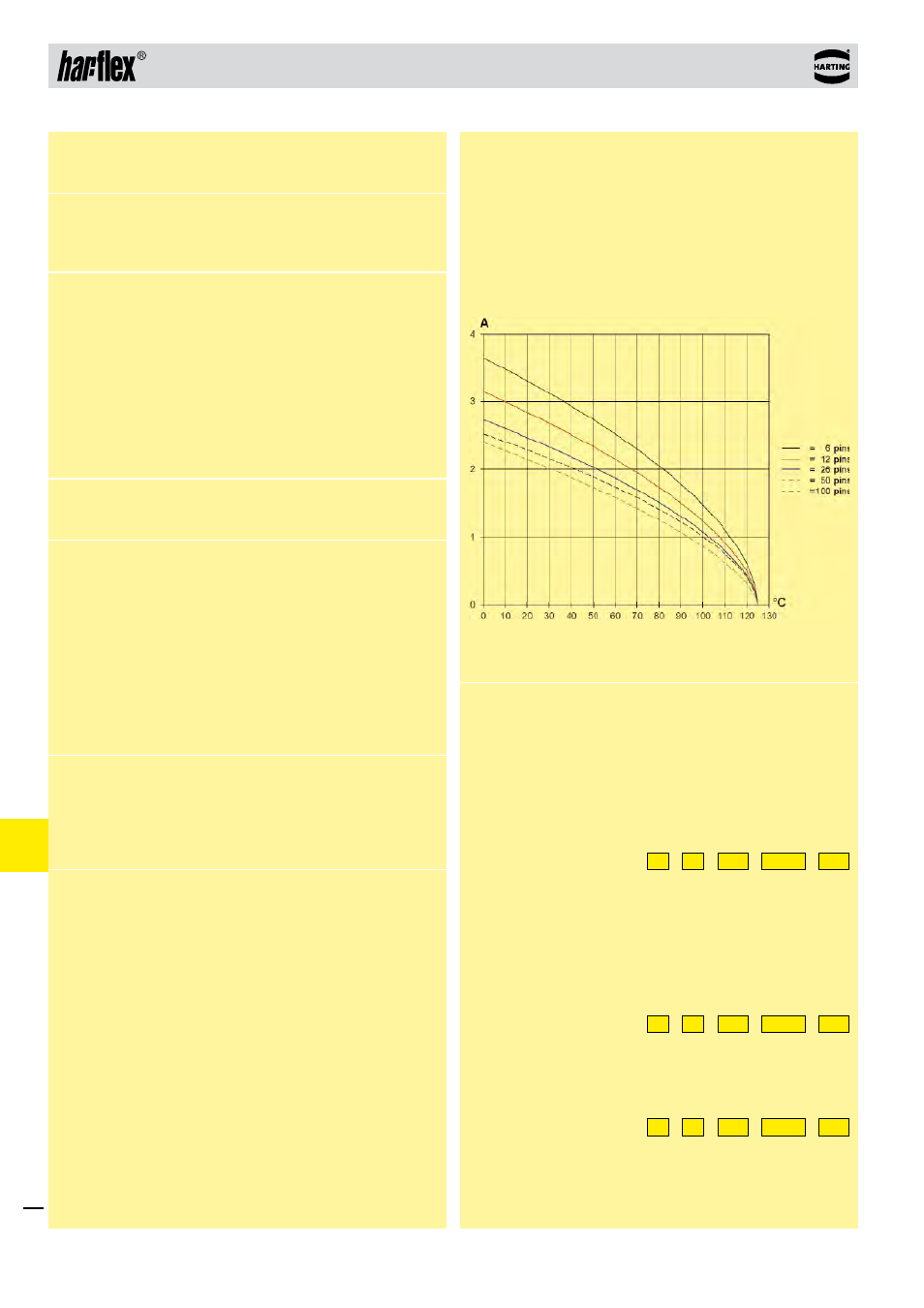

Derating curve at I

max

* 0.8 (IEC 60 512-5-2)

Technical characteristics

Current carrying capacity

acc. to IEC 60 512-5-2

The current carrying capacity is limited by maximum temperature

of materials for inserts and contacts including terminals.

The current capacity-curve is valid for continuous, not interrupted

current-loaded contacts of connectors when simultaneous

power on all contacts is given, without exceeding the maximum

temperature.

Control and test procedures according to DIN IEC 60 512-5-2.

Durability

Performance level 1 (recommended for majority of applications)

Initial 250 mating cycles, 10 days gas test (25 °C/75 % r.h.)

using H

2

S 10 ppb, NO

2

200 ppb, CL

2

10 ppb, SO

2

200 ppb.

Measurement of contact resistance. The remaining 250 mating

cycles are subject to measurement of contact resistance and

visual inspection. Visual inspection. No abrasion of the contact

finish through to the base material. No functional impairment.

Part number definition:

Performance level 2

Initial 125 mating cycles, 4 days gas test (25 °C/75% r.h.) using H

2

S

10 ppb, NO

2

200 ppb, CL

2

10 ppb, SO

2

200 ppb. Measurement of

contact resistance. The remaining 125 mating cycles are subject

to measurement of contact resistance and visual inspection.

Visual inspection. No abrasion of the contact finish through to

the base material. No functional impairment.

Part number definition:

Performance level S4

Defined contact surface of min. 0.06 µm Au over 0.7+0.2 µm PdNi.

Part number definition:

Number of contacts

6, 8, 10 … 96, 98, 100

Connector pitch

1.27 mm x 1.27 mm

[0.050’’ x 0.050’’]

Clearance and creepage distance

Board connectors (SMT)

min. 0.4 mm

Cable connectors (IDC)

AWG 30/1 (solid)

min. 0.35 mm

AWG 30/7 (stranded)

min. 0.4 mm

Test voltage U

r.m.s.

500 V

Contact resistance

< 25 mΩ

Insulation resistance

> 10 GΩ

Insertion and withdrawal force

approx. 0.5 N / contact

Working temperature range

for connectors:

– 55 °C … + 125 °C

for flat cable assembly:

depends on cable type

The higher temperature limit

includes the local ambient and

heating effects of the contacts

under load

Temperature during reflow soldering min. 150 s > 217 °C

(acc. to ECA/IPC/JEDEC

min. 30 s > 240 °C

J-STD-075 Level PSL R0)

Electrical termination

Board connectors

SMT (Surface Mount Technology)

Cable connectors

IDC (Insulation

Displacement Connection)

Materials

Moulding material

LCP

UL approval

UL 94-V0

CTI value

(Comparative Tracking Index)

175

Contacts base material

Copper alloy

Contact surface

Mating

side

Board connectors

Au over PdNi

(acc. performance level)

Cable connectors

Au over PdNi

(acc. performance level)

Termination

side

Board

connectors

(SMT)

Sn

Cable

connectors

(IDC)

Sn