Generator start-up procedure (manual) – Multiquip DCA250SSI User Manual

Page 35

DCA250SSI 3-POSITION WHEEL GEN. • OPERATION AND PARTS MANUAL — REV. #0 (01/13/10) — PAGE 35

GENERATOR START-UP PROCEDURE (MANUAL)

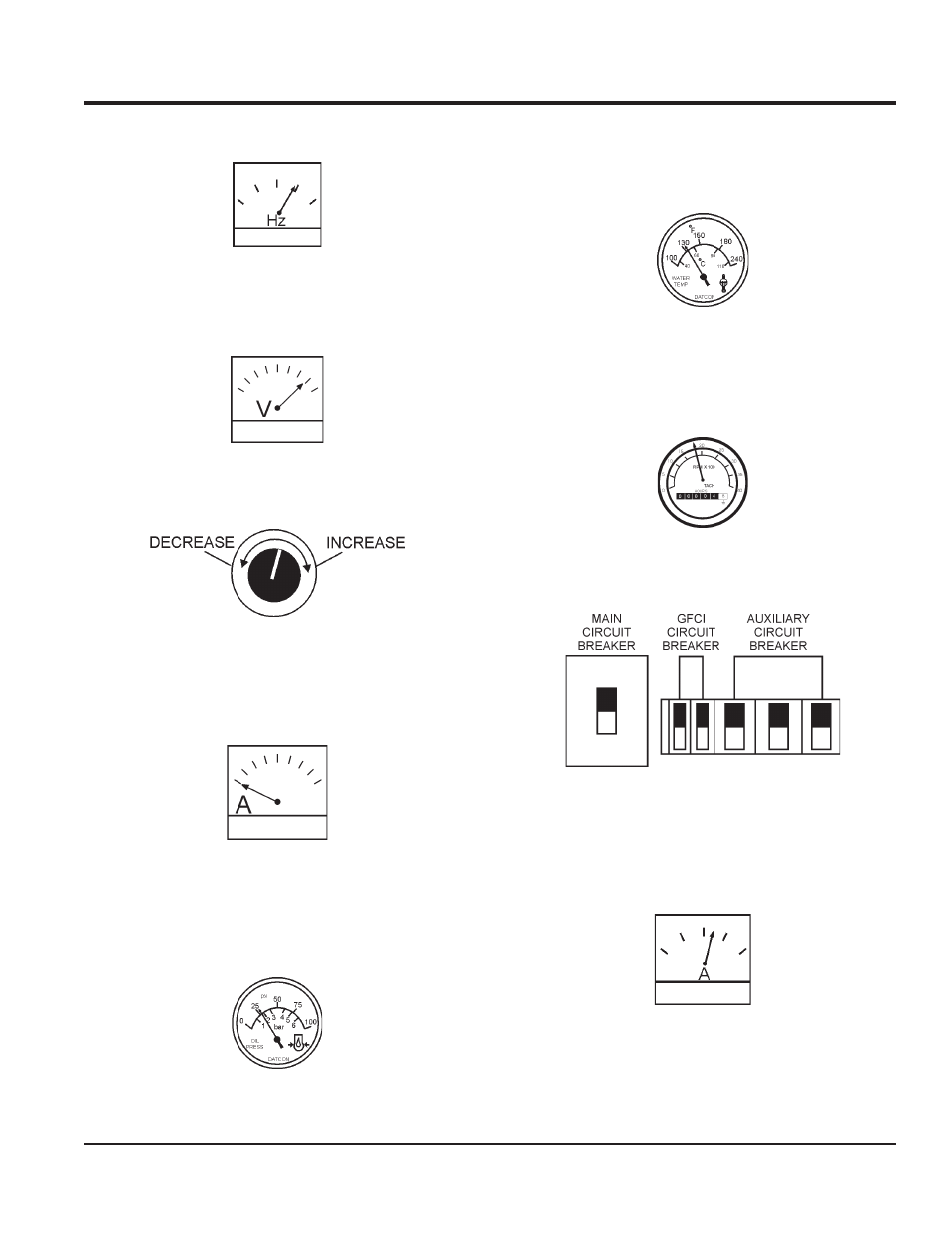

7. The generator’s frequency meter (Figure 43) should be

displaying the 60 cycle output frequency in HERTZ.

Figure 43. Frequency Meter

8. The generator’s AC-voltmeter (Figure 44) will display

the generator’s output in VOLTS. If the voltage is not

within the specifi ed tolerance, .

Figure 44. Voltmeter

9. Use the voltage adjustment control knob (Figure 45)

to increase or decrease the desired voltage.

Figure 45. Voltage Adjust Control Knob

10. The ammeter (Figure 46) will indicate zero amps with

no load applied. When a load is applied, the ammeter

will indicate the amount of current that the load is

drawing from the generator.

Figure 46. Ammeter (No Load)

11. The engine oil pressure gauge (Figure 47) will indicate

the oil pressure of the engine. Under normal operating

conditions the oil pressure is approximately 28 to 85

psi. (193~586 kPa).

Figure 47. Oil Pressure Gauge

12. The coolant temperature gauge (Figure 48) will

indicate the coolant temperature. Under normal

operating conditions the coolant temperature should

be between 167°~203°F (75°~95°C) (Green Zone).

Figure 48. Coolant Temperature Gauge

13. The tachometer gauge (Figure 49) will indicate the

speed of the engine when the generator is operating.

Under normal operating conditions this speed is

approximately 1800 RPM’s.

Figure 49. Engine Tachometer Gauge

14. Place the main, GFCI, and aux. circuit breakers in the

ON position (Figure 50).

Figure 50. Main, Aux. and GFCI

Circuit Breakers (ON)

15. Observe the generator’s ammeter (Figure 51) and

verify it reads the anticipated amount of current with

respect to the load. The ammeter will only display a

current reading if a load is in use.

Figure 51. Ammeter (Load)

16. The generator will run until manually stopped or an

abnormal condition occurs.