Maintenance/troubleshooting (electric motor) – Multiquip SP1E16A User Manual

Page 22

page 22 — Sp1e16a paVeMeNT SaW • operaTioN MaNual — reV. #0 (04/14/10)

MaintenanCe/trOubleSHOOting (eleCtriC MOtOr)

Chassis lubrication

Blade Shaft Bearings — Two zerk fittings are located

at the lower-front area of the saw. Lubricate before daily

use. Use a good quality automotive or general purpose

grease. Check and lubricate more often if unit is under

heavy use. Do not overfill bearings. Overfilling can

damage the grease seals which can result in bearing

exposure to dirt and contaminants which can then

shorten the life of the bearings. Excess grease can also

drip onto the cutting surface.

V-Belt

See "V-belt Alignment and Tensioning" section in this

manual.

TrouBleSHooTiNg

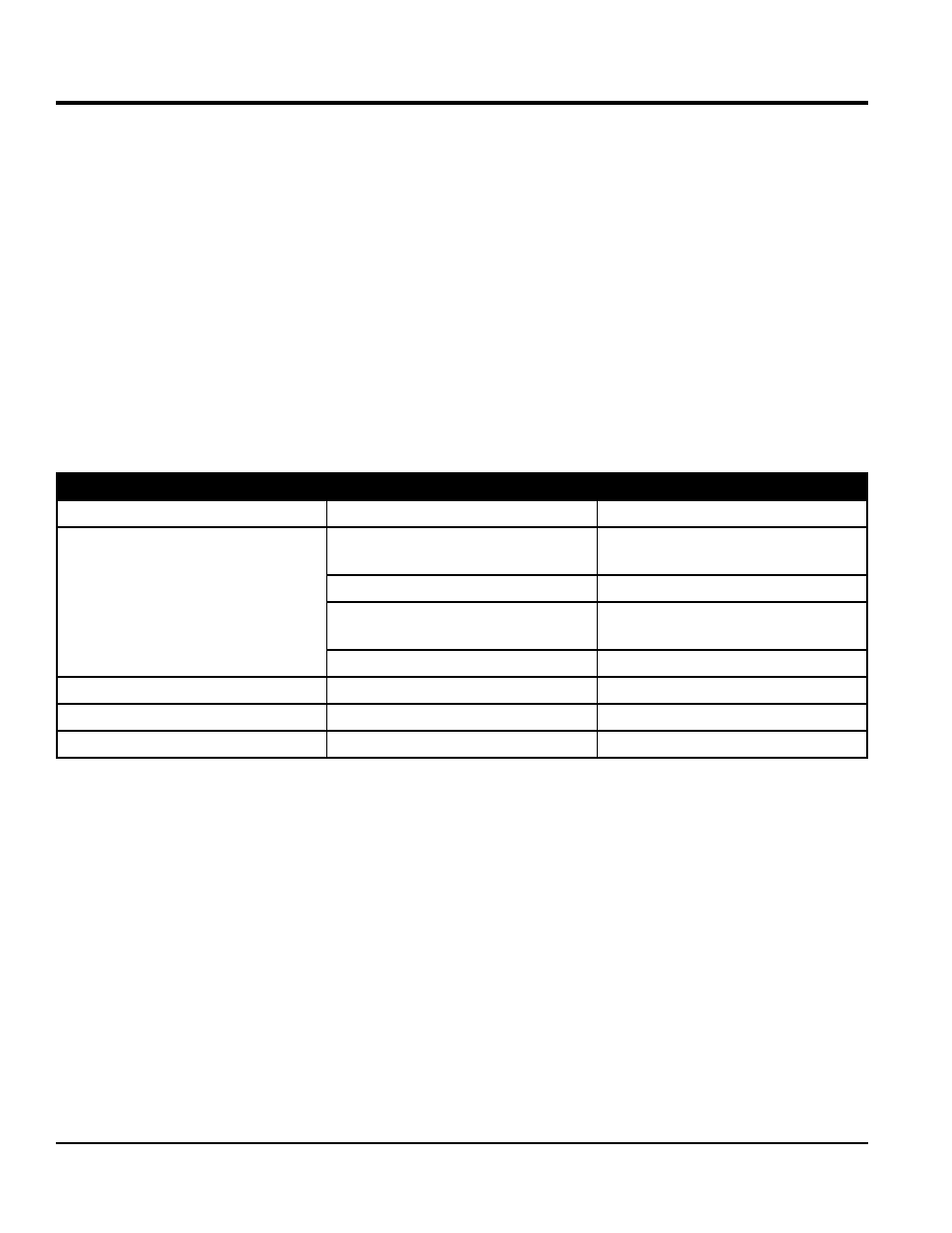

Table 4. Troubleshooting (electric Motor)

Symptom

possible Cause

Solution

Electric motor will not start.

Is there power?

Check power source. Check reset

button.

Is power cable plugged in?

Plug in power cable.

Is ON/OFF switch placed in ON

position?

Place ON/OFF switch in ON position.

Defective cable?

Check cable.

Electric motor continuously stops.

Reset button OK?

Check power source.

Electric motor RPM's too low.

Low voltage?

Check input voltage (230 VAC).

Electric motor RPM's too high.

High voltage?

Check input voltage (230 VAC).