Lifting the trowel onto a slab, Heavy duty extension cord, Emergency stop switch – Multiquip EPOXY/M SERIES User Manual

Page 28: Correct, Connect one end of a, Make sure to connect the

PAGE 28 —EPOXY SERIES WALK-BEHIND TROWEL— OPERATION AND PARTS MANUAL — REV. #5 (10/06/10)

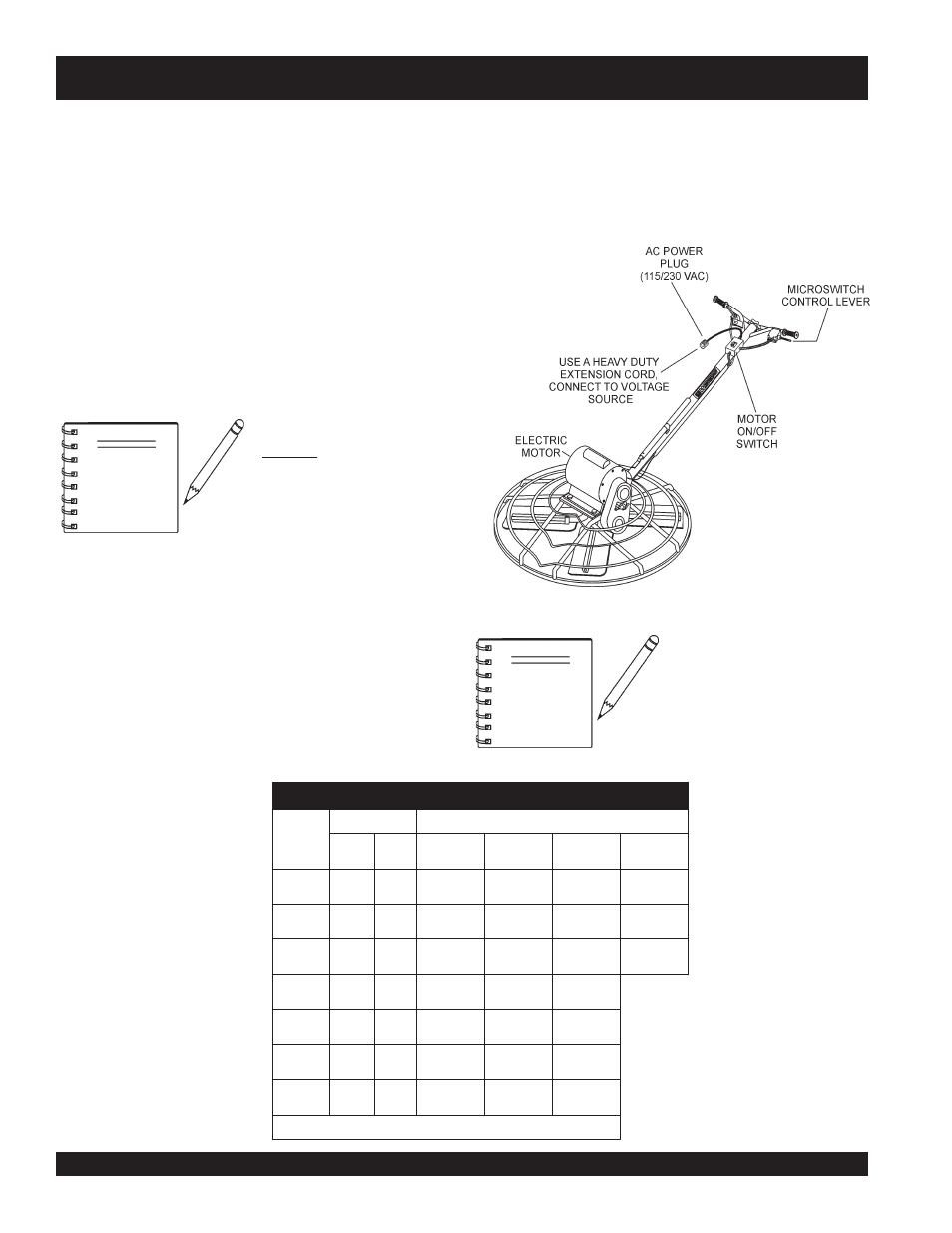

EPOXY/M SERIES TROWEL — INITIAL START-UP (ELECTRIC MOTOR)

Starting The Electric Motor (Single Phase 115/230 Volts)

The electric motor used on the B-Series trowel has two operating

voltages:

■ 115 VAC Single Phase, 2 Horsepower

■ 230 VAC Single Phase, 2 horsepower

1. Lift the trowel onto the slab in the same manner as described

on page 24 ("

Lifting the Trowel Onto a Slab

").

2. Connect one end of a

heavy duty extension cord

to the

AC power plug on the trowel.

3. Connect the other end of the extension cord to an AC power

source.

Extension Cable

When electric power is to be provided to the trowel at some

distance from the power source, extension cords are normally

used. Cables should be sized to allow for distance in length and

amperage so that the voltage drop between the power source

and point of use (trowel) is held to a minimum. Use the cable

selection chart (Table 4) as a guide for selecting proper extension

cable size.

At 115 VAC the motor should

draw about 16.6 amps and at

230 VAC the motor should draw

about 8.4 amps.

Figure 26. Electric Motor Trowel

4. Squeeze the micro-switch lever ( Figure 26) to begin trow-

eling. This lever will act an

emergency stop switch

. When

this lever is released, voltage to the electric motor will be

interrupted. When this lever is squeezed the voltage will

resume. This can only be accomplished if the trowel's power

ON/OFF switch is in the ON position.

)

n

o

i

t

a

r

e

p

O

e

s

a

h

P

e

l

g

n

i

S

,

z

H

0

6

(

n

o

i

t

c

e

l

e

S

e

l

b

a

C

.

4

e

l

b

a

T

n

i

t

n

e

r

r

u

C

s

e

r

e

p

m

A

s

t

t

a

W

n

I

d

a

o

L

h

t

g

n

e

L

e

l

b

a

C

e

l

b

a

w

o

ll

A

m

u

m

i

x

a

M

0

2

1

t

A

s

t

l

o

V

0

4

2

t

A

s

t

l

o

V

e

r

i

W

0

1

#

e

r

i

W

2

1

#

e

r

i

W

4

1

#

e

r

i

W

6

1

#

5

.

2

0

0

3

0

0

6

.t

f

0

0

0

1

)

m

5

0

3

(

.t

f

0

0

6

)

m

3

8

1

(

.t

f

5

7

3

)

m

7

0

1

(

.t

f

0

5

2

)

m

6

7

(

5

0

0

6

0

0

2

1

.t

f

0

0

5

)

m

2

5

1

(

.t

f

0

0

3

)

m

1

9

(

.t

f

0

0

2

)

m

1

6

(

.t

f

5

2

1

)

m

8

3

(

5

.

7

0

0

9

0

0

8

1

.t

f

0

5

3

)

m

7

0

1

(

.t

f

0

0

2

)

m

1

6

(

.t

f

5

2

1

)

m

8

3

(

.t

f

0

0

1

)

m

0

3

(

0

1

0

0

2

1

0

0

4

2

.t

f

0

5

2

)

m

6

7

(

.t

f

0

5

1

)

m

5

4

(

.t

f

0

0

1

)

m

0

3

(

5

1

0

0

8

1

0

0

6

3

.t

f

0

5

1

)

m

6

4

(

.t

f

0

0

1

)

m

0

3

(

.t

f

5

6

)

m

9

1

(

0

2

0

0

4

2

0

0

8

4

.t

f

5

2

1

)

m

8

3

(

.t

f

5

7

)

m

2

2

(

.t

f

0

5

)

m

5

1

(

0

3

0

0

6

3

0

0

2

7

.t

f

5

7

)

m

3

2

(

.t

f

0

5

)

m

5

1

(

.t

f

5

3

)

m

1

1

(

.

e

g

a

tl

o

v

w

o

l

m

o

r

f

tl

u

s

e

r

n

a

c

e

g

a

m

a

d

t

n

e

m

p

i

u

q

E

:

N

O

I

T

U

A

C

Make sure to connect the

correct

AC voltage (115 or

230 VAC) to the electric motor.

Connecting an incorrect

voltage could cause serious

damage to the electric motor.

The identification plate located

on the motor will indicate the

motor's voltage requirement.

NOTE

NOTE