Hpla/hpha-series 36" trowel — maintenance – Multiquip HPHA-SERIES User Manual

Page 34

PAGE 34 — HPLA/HPHA-SERIES 36" WALK-BEHIND TROWEL— OPERATION AND PARTS MANUAL — REV. #3 (07/06/10

)

Trowel Arm Adjustment

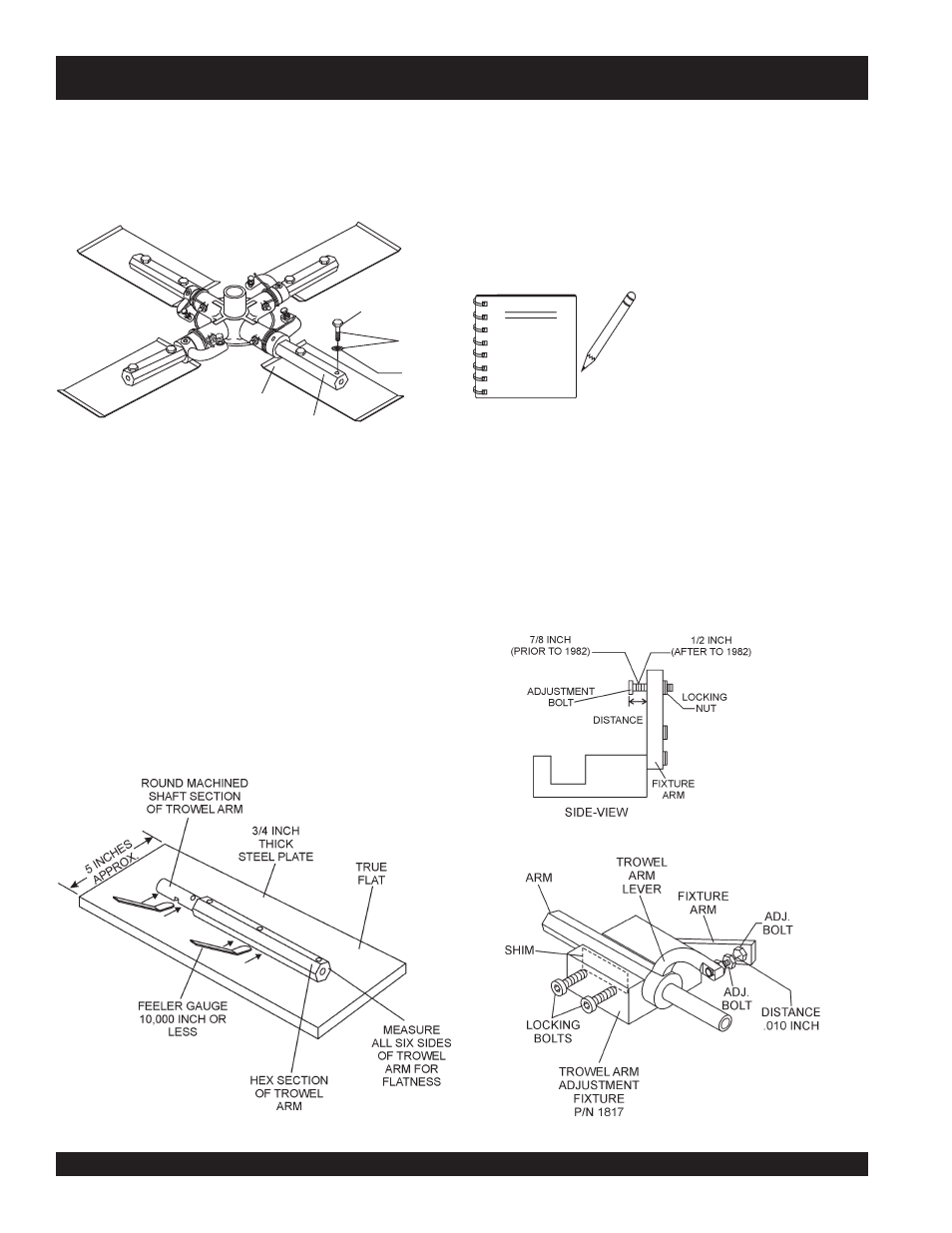

Shown in (Figure 48) is the adjustment fixture with a trowel arm

inserted. As each trowel arm is locked into the fixture, the arm bolt

is adjusted to where it contacts a stop on the fixture. This will

consistently adjust all of the trowel arms, keeping the finisher as

flat and evenly pitched as possible.

1. Locate the trowel arm adjustment tool P/N 1817. Set the

adjustment tool for a clock-wise blade rotation, meaning the

fixture arm is in the "UP" position.

Figure 48. Trowel Arm Adjustment Tool

Trowel Arm Flatness Test

1. Using a piece of 3/4 inch thick steel plate or any surface which

is

true

and

flat

, check all

six sides

of each trowel arm for

flatness.

2. Check each of the six sides of the trowel arm (hex section

only) using a ten thousands of an inch (max.) feeler gauge

(Figure 47) between the flat of the trowel arm and an

ex

-

tremely flat

test surface.

3. If the trowel arm is found to be

uneven

or

bent

, replace the

trowel arm. A bent trowel will not allow the trowel to operate

in a smooth fluid rotation.

4. Next, check each of the six sides of the round machined shaft

section of the trowel arm. Each section should have the

same

clearance

between the round of the trowel arm shaft and the

test surface.

Figure 47. Trowel Arm Flatness Test

HPLA/HPHA-SERIES 36" TROWEL — MAINTENANCE

Trowel Blade Removal

1. Remove the trowel blades from the trowel arm by removing

the three hex head bolts (Figure 46) from the trowel arm. Set

blades aside.

Figure 46. Trowel Blades

2.

Wire brush

any build-up of concrete from all six sides of the

trowel arm. Repeat this for the remaining three arms.

NOTE

Trowel arms can be damaged by

rough handling or by striking

exposed plumbing or forms while in

operation.

ALWAYS look-out for

objects which might cause damage

to the trowel arms.

REMOVE

LOCK

WASHER

HEX

HEAD

BOLT

BLADE

ARM