Ja-series trowel— pre-inspection – Multiquip JA-SERIES User Manual

Page 23

JA-SERIES WALK-BEHIND TROWEL — OPERATION AND PARTS MANUAL — REV. #9 (07/02/10) — PAGE 23

JA-SERIES TROWEL— PRE-INSPECTION

Fuel Check

Motor fuels are highly flammable and can be dangerous if

mishandled. DO NOT smoke while refueling. DO NOT attempt

to refuel the trowel if the engine is

hot!

or

running

.

Explosive Fuel

Blade Check

Check for worn or damaged blades. Check to see if one blade is

worn out while the others look new. If this is the case there could

be a blade pitch problem. Refer to the maintenance section of

this manual for blade pitch adjustment procedure. Replace any

worn blades.

CONTROLS

Safety Kill Switches

This trowel has been equipped with a safety kill switch or a hand

operated clutch. Safety kill switches or hand clutches should be

tested every time the engine is started.

Centrifugal Type Kill Switch

The switching mechanism of this switch (Figure 20) should

operate freely and should

always

be kept in this condition. With

the switch in the OFF position, the engine should not start or run.

The purpose of this switch is to stop the engine in a runaway

situation, (i.e.-the operator releasing the handle during operation).

NOTE

NEVER!

disable or disconnect the kill switch.

It is provided for operator safety. Injury may

result if it is disabled, disconnected or

improperly maintained.

Hand Clutch

Some finisher models are equipped with a

hand operated

clutch. These units are not equipped with a safety kill switch. The

unit automatically stops rotating when the clutch lever is released.

DO NOT let the machine sit unused with the engine at high speed

for an extended period of time. It will cause premature belt wear

or may destroy the belt. Always set the engine speed to idle when

the hand clutch is disengaged.

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if fuel level is low. If fuel is low, replenish

with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel.

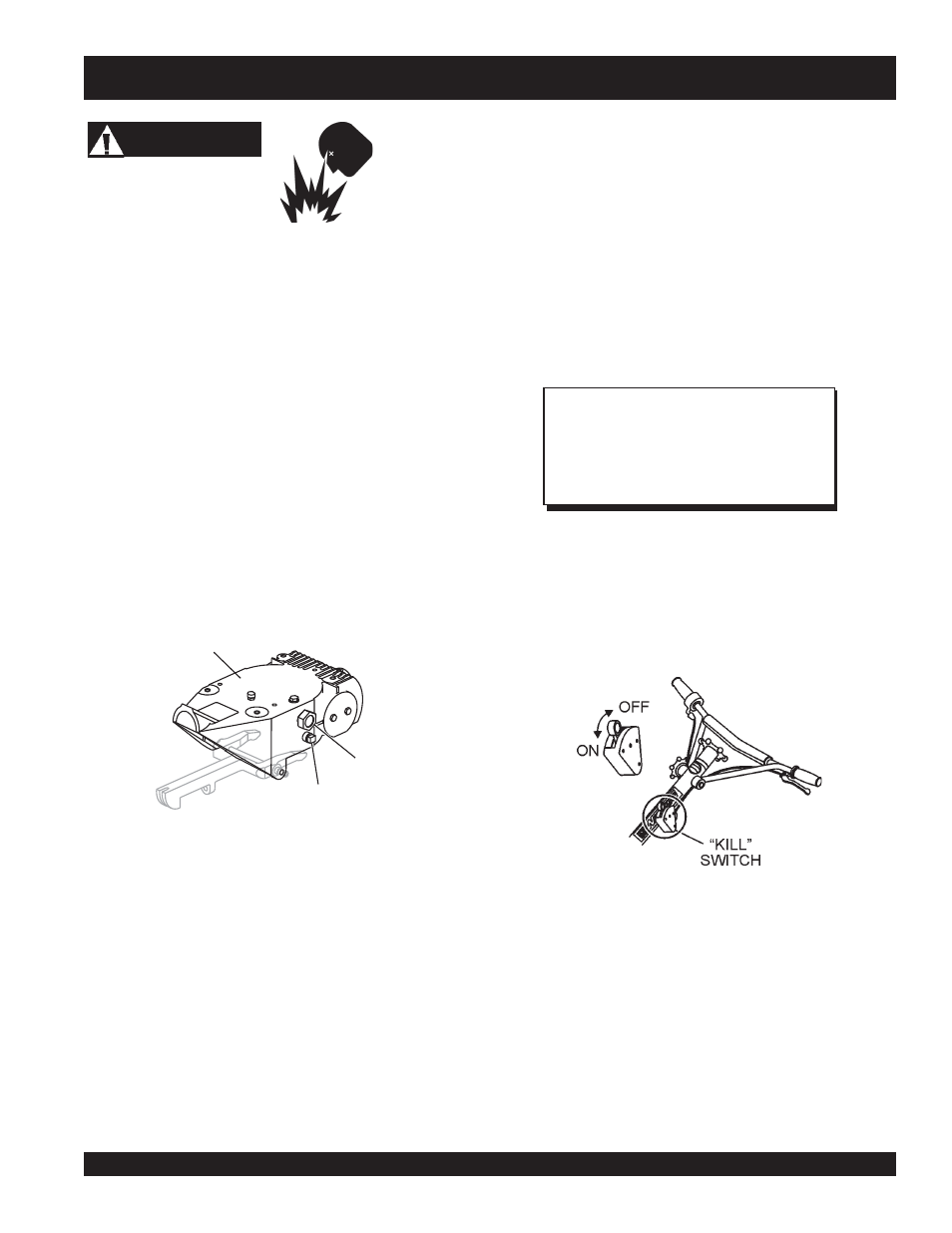

Gearbox Oil

1.

Determine if the

gearbox

oil is low by removing the oil

plug located on the side of the gearbox. This plug will be

marked by the "

check

" decal. See (Figure 19). The correct

level of the lubrication oil should be to the bottom of the fill

plug.

Figure 19. Gearbox

2.

If oil does not reach the middle of the

sight glass

fill with

type ISO 680 (Whiteman P/N 10139) gearbox lubricant oil

until the oil level reaches the middle of the sight glass.

Figure 20. Centrifugal Kill Switch

GEARBOX

DRAIN

PLUG

OIL SIGHT/

FILL PLUG

V-belt Check

A worn or damaged V-belt can adversely affect the performance

of the trowel. If a V-belt is defective or worn, simply replace the V-

belt as outlined in the maintenance section of this manual.