Porto-screed psh — operation – Multiquip PSH User Manual

Page 18

PAGE 18 — STOW PORTO-SCREED — OPERATION & PARTS MANUAL — REV. #1 (03/17/04)

OPERATION

PORTO-SCREED PSH — OPERATION

DO NOT

alter.this setting since

damage to the eccentric bearings

can result and both the engine

and machine warranty will be

automatically VOIDED.

4. Start the engine as previously described. Refer to the

Engine Manual Starting Instructions for complete starting

instructions of the engine. Allow the engine to warm up 1-2

minutes before operating. The throttle lever should be set

to permit the engine to warm up WITHOUT engaging the

centrifugal clutch and causing the machine to vibrate and

move forward under its own power.

5. To begin operation move the throttle lever (Item C, Figure

18) to the high speed or “Full Throttle” position quickly to

prevent damage from occurring to the clutch. The “Full

Throttle” position of this machine has been pre-set at the

factory.

For beam lengths up to 14 ft. (4.2

meters) "2x4" wooden or

lightweight beams are

recommended. For longer lengths,

up to 20 ft. (6 meters), "2x6" beams

should be used.

Do not over tighten the clamping studs. Check the clamping

studs periodically during operation and retighten them if

they loosen.

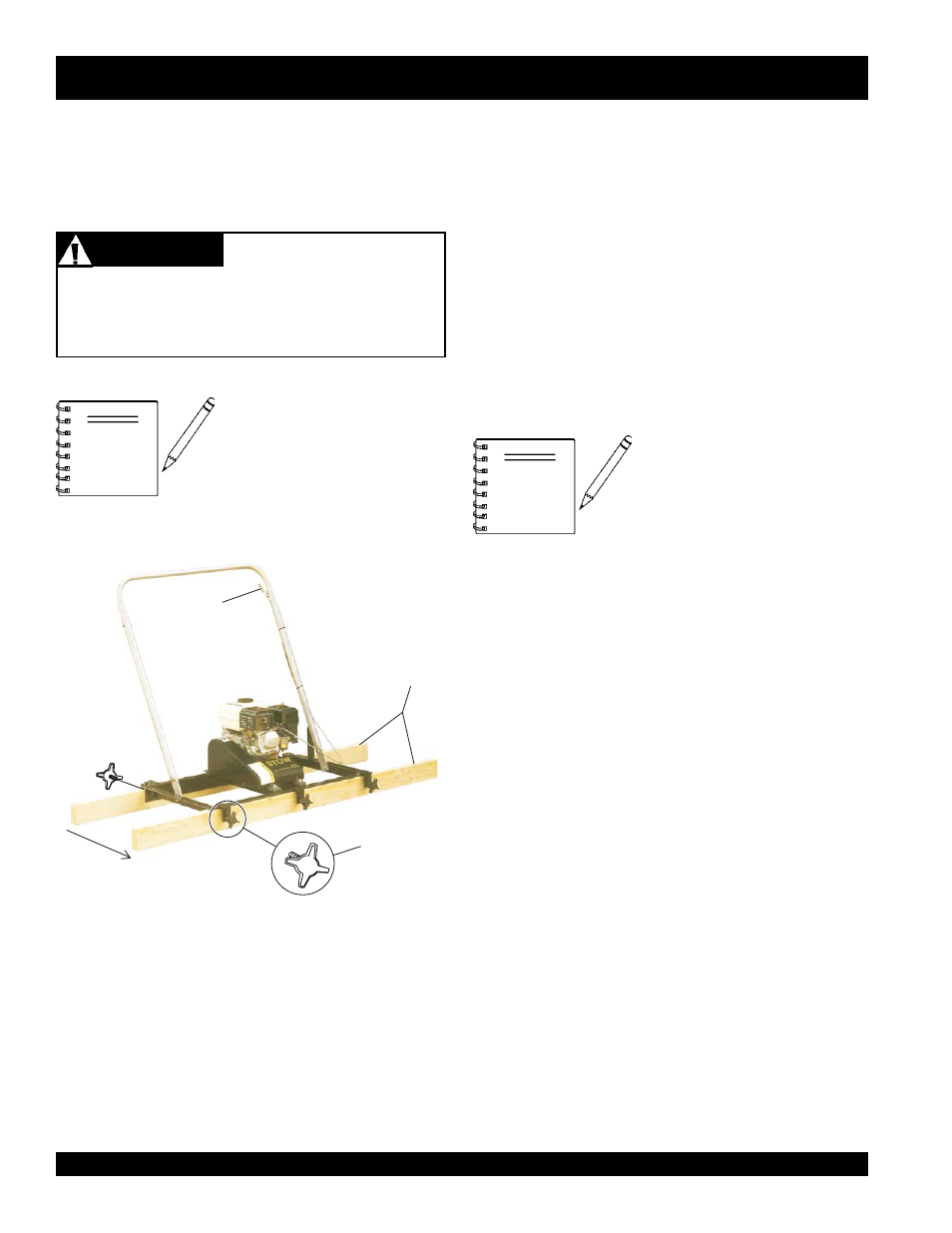

1. Place the machine on the screeding beams (Items B,

Figure 18) and install the clamping studs (Items A).

NOTE

Figure 18. Screeding Beams

2. Position the screed on the forms with the eccentric facing

the desired direction of travel.

3. Pour the concrete into the forms to a height just above the

bottom edge of the sceeding beams and at least 10 ft.

ahead of the unit.

NOTE

Stopping The Engine

1. Move the throttle lever to the

IDLE

or

SLOW

position (Item

C, Figure 15) and run the engine for three minutes at low

speed.

2. After the engine

cools

, turn the engine start/stop switch to the

“

OFF

” position (Figure 16).

A

B

C

TRA

VEL

CAUTION