Em-120sm — maintenance, Caution – Multiquip EM120SM User Manual

Page 18

PAGE 18 — ESSICK EM-120SM— OPERATION AND PARTS MANUAL — REV. #5 (03/29/10)

NOTE

This connector pin bolt is special. When replacing this

bolt consult the parts section of this manual for the

correct part number.

BEARING BRACKET

Grease the bearing bracket every month.

CLEANING

Always disconnect the spark plug wire before cleaning the inside

of the drum.

Never pour or spray water over the gasoline engine or electric

motor.

For consistent performance, long life and high quality mixing,

thoroughly clean the mixer inside and out at the end of each

day’s operation. To prevent lumps of dried mortar from forming

and contamination of future batches, do not allow a buildup of

materials to form on the blades or anywhere inside the drum.

EM-120SM — MAINTENANCE

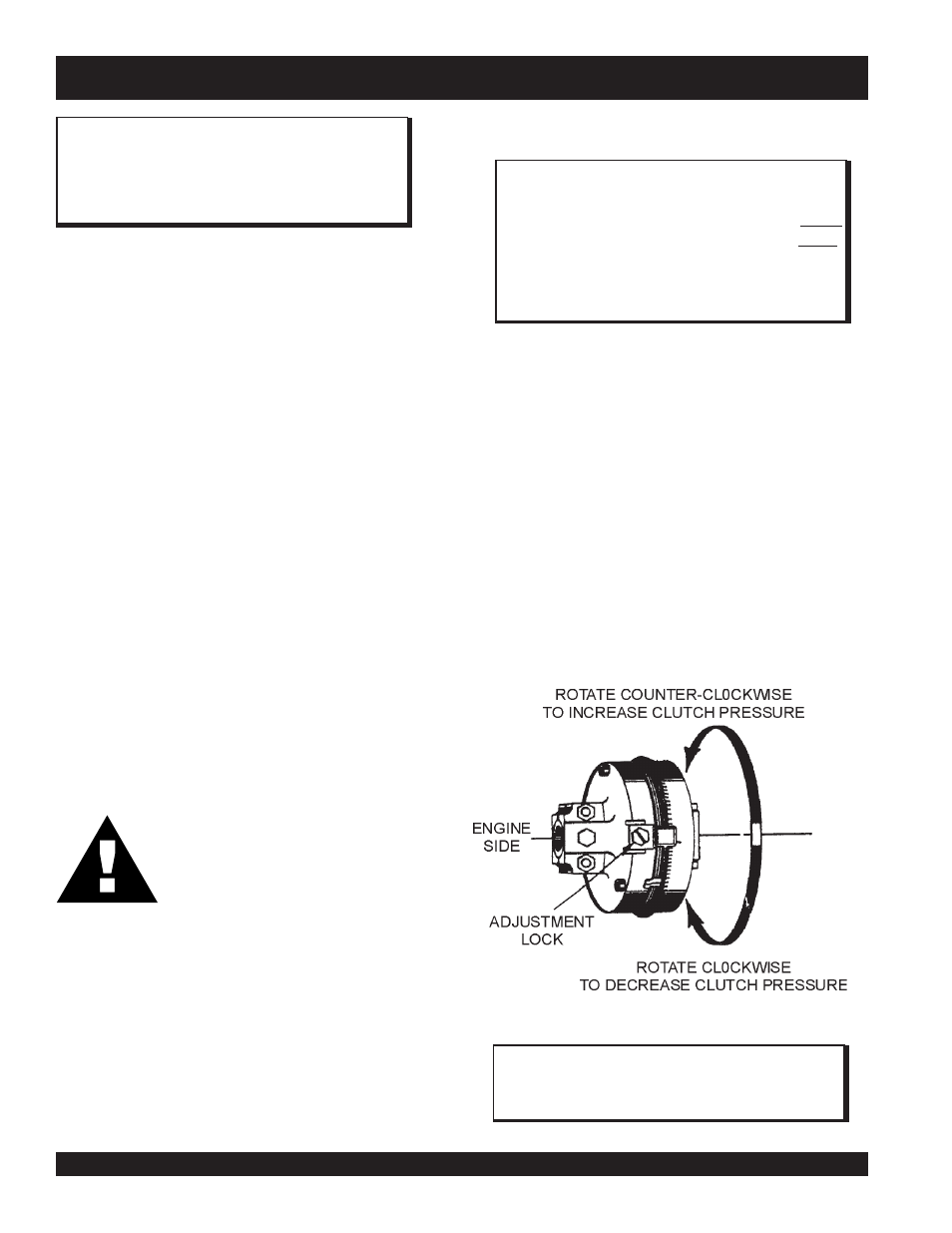

Clutch Adjustment Mechanical 12 CF Mixer

If the rotating mixing paddles appear to be losing rotational speed,

it may be necessary to adjust the clutch. For optimum

performance Multiquip recommends 35-55 lbs. applied pressure

to the hand clutch lever. After the first initial operating hours (8)

check the clutch for proper ensasment pressure.

CAUTION:

Always stop the engine, disconnect the spark

plug or electrical power cord before attempting

this procedure.

1.

To gain access to the " Gear Reduction Compartment"

remove the four 9/16-inch hex head bolts that secure the

hood to the engine and remove engine hood.

2.

Drain the clutch compartment oil by removing the magnetic

3/8 plug located at the bottom of the Gear Reduction

Assembly.

3.

To gain access to the "

clutch Inspection door

" remove

the six 1/2-inch capscrews and lockwashers that secure

the clutch inspection door. Remove door and gasket.

NOTE

The Gear Reduction Compartment consist of two

compartments, a lower and upper.The

lower

compartment houses the clutch, the

uppe

r

compartment contains the actual gear reduction.

Remember each compartment requires a different type

of lubricating oil.

4.

Check that the clutch is disengaged by pulling the shifter

lever towards the rear of the mixer.

5.

Refer to Figure 12 for steps 5A through 5G:

A. Rotate the clutch using the recoil starter until the

adjustment

lock

(Figure 11) P/N EM934040 is visible.

Using a flat blade screwdriver loosen the adjustment bolt

just enough to release the adjustment lock.

B. Using a punch, rotate the

adjusting ring

P/N EM 934045

one notch at a time in the counter-clockwise direction until

a firm 35 to 55 lbs. pressure is felt when engaging the

clutch lever (the lever should snap into the engaged

position).

Figure 11. Clutch Adjustment Lock Location

NOTE

If the clutch cannot be adjusted, it may be necessary to

inspect or replace the clutch.

Clutch Adjustment Procedure