Troubleshooting (engine/pump) – Multiquip QP3TZ User Manual

Page 25

QP3TZ TRASH PUMP • OPERATION AND PARTS MANUAL — REV. #4 (05/15/14) — PAGE 25

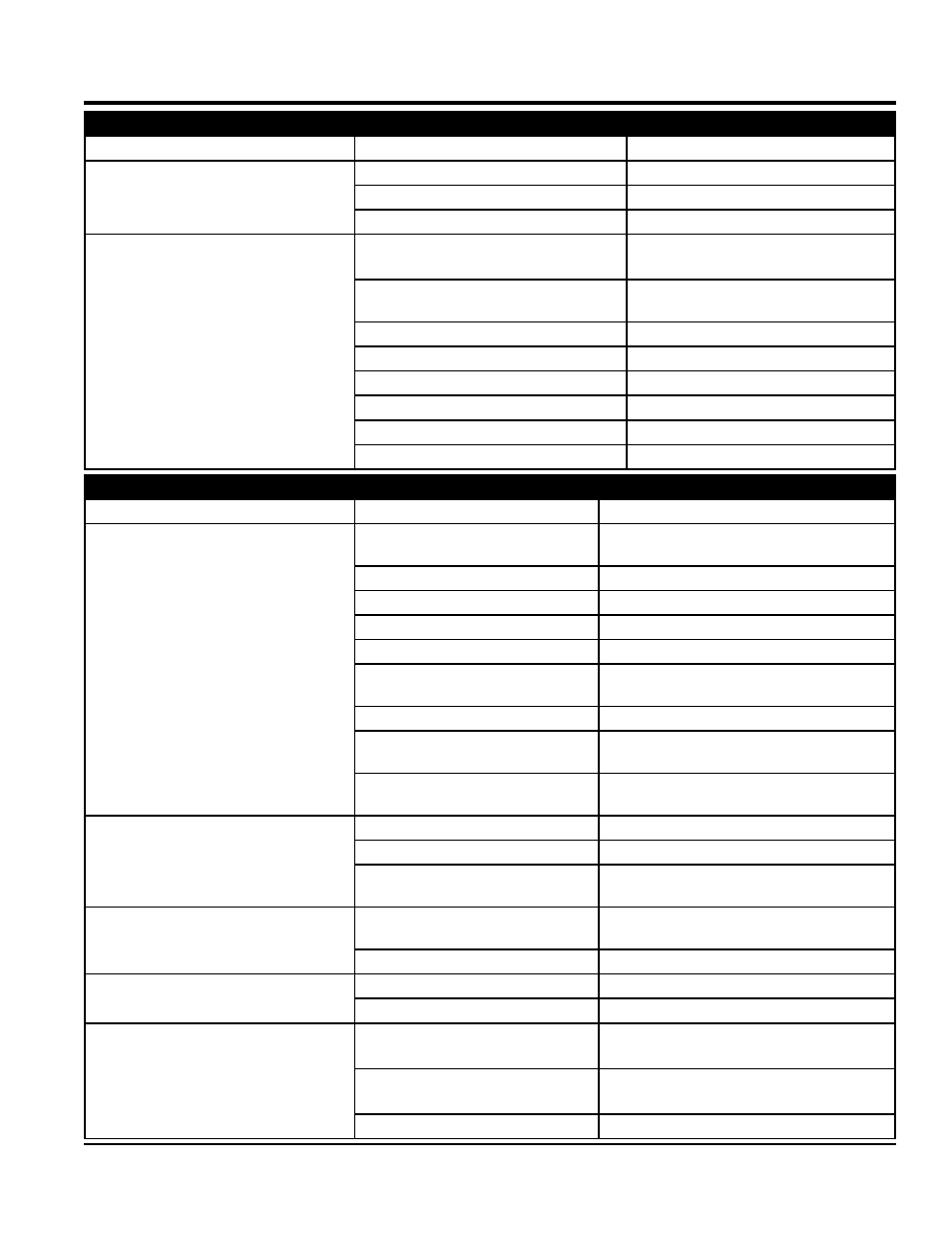

TROUBLESHOOTING (ENGINE/PUMP)

Troubleshooting (Engine) - continued

Symptom

Possible Problem

Solution

Low engine power output and low speed,

black exhaust smoke.

Air filter blocked?

Clean or replace air filter.

Incorrect valve clearances?

Adjust valves per engine specification.

Malfunction at injector?

See engine manual.

Engine overheats.

Too much oil in engine crankcase?

Drain off engine oil down to uppermark on

dipstick.

Entire cooling air system contaminated/

blocked?

Clean cooling air system and cooling fin

areas.

Fan belt broken or elongated?

Change belt or adjust belt tension.

Coolant insufficient?

Replenish coolant.

Radiator net or radiator fin clogged with dust? Clean net or fin carefully.

Fan, radiator, or radiator cap defective?

Replace defective part.

Thermostat defective?

Check thermostat and replace if necessary.

Head gasket defective or water leakage?

Replace parts.

Troubleshooting (Trash Pump)

Symptom

Possible Problem

Solution

Pump does not take on water.

Not enough priming water in the

housing?

Add water.

Engine speed too low?

Increase throttle.

Strainer plugged?

Clean strainer.

Suction hose damaged?

Replace or repair hose, and clamps.

Air leak at suction port?

Check that fittings are tight and properly sealed.

Pump is located too high above water

line?

Move pump closer to water.

Debris collecting in pump housing?

Clean pump housing.

Too much distance between impeller and

volute?

Adjust clearance by adding shims or replace

impeller. Min. .006 inch - Max. .020 inch

Water leaking out weep hole between

pump and engine?

Check condition of mechanical seal and gaskets,

between pump end and engine housing.

Pump takes in water, little or no discharge.

Engine speed too low?

Increase throttle speed.

Suction strainer partially plugged?

Clean strainer.

Impeller/Volute worn?

Adjust clearance by adding shims or replace

impeller/volute.

Suction hose leaks at inlet.

Fittings/clamps are not sealed properly? Tighten, replace or add clamp. (Keep extra seals

on pump).

Hose diameter is too large?

Use smaller diameter hose or replace hose.

Discharge does not stay on coupling.

Pressure too high?

Check pressure, add additional clamp.

Hose kinked or end blocked?

Check hose.

Impeller does not turn, pump is hard to start.

Impeller jammed or blocked?

Open pump cover and clean dirt and debris from

inside housing.

Impeller and volute binding?

Adjust clearance by removing shim from behind

impeller.

Defective engine?

See Engine Owner's Manual.